Cutter shaft of crusher and film crushing processing method

A technology of crusher and cutter shaft, which is applied in the direction of mechanical material recycling, grain processing, plastic recycling, etc., can solve the problems of material jam, low efficiency and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0034] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with examples of implementation and accompanying drawings. The present invention can be implemented in the following ways:

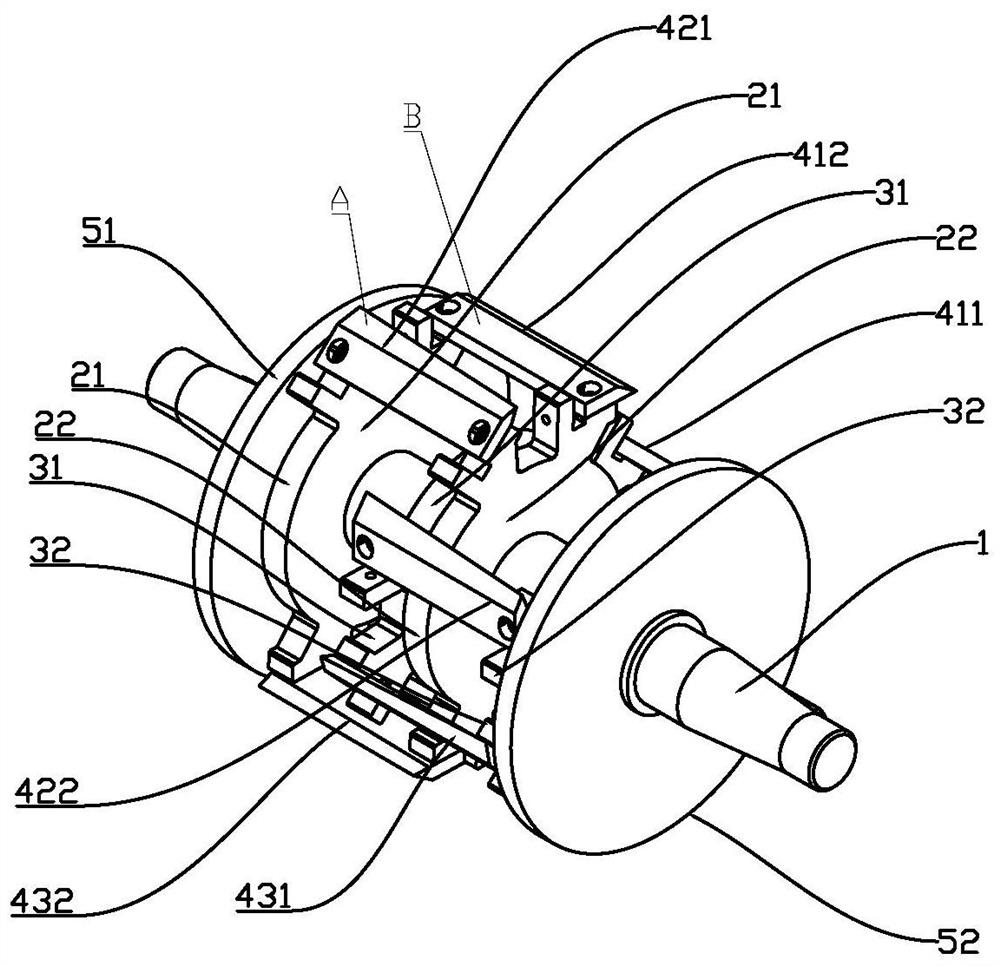

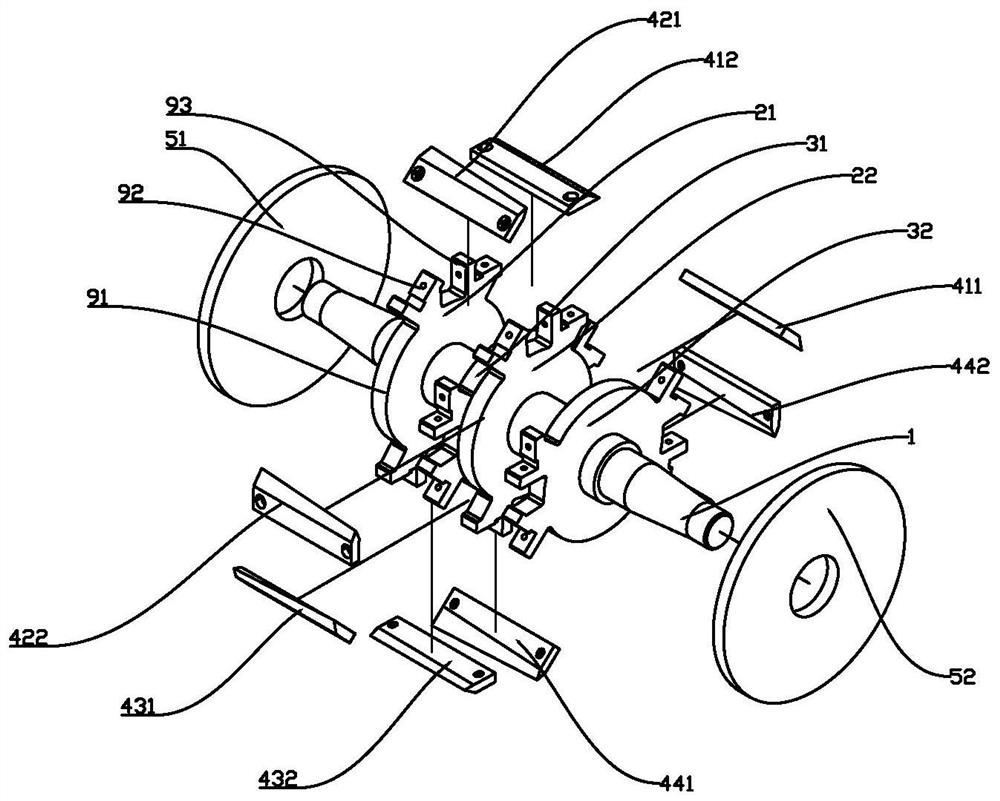

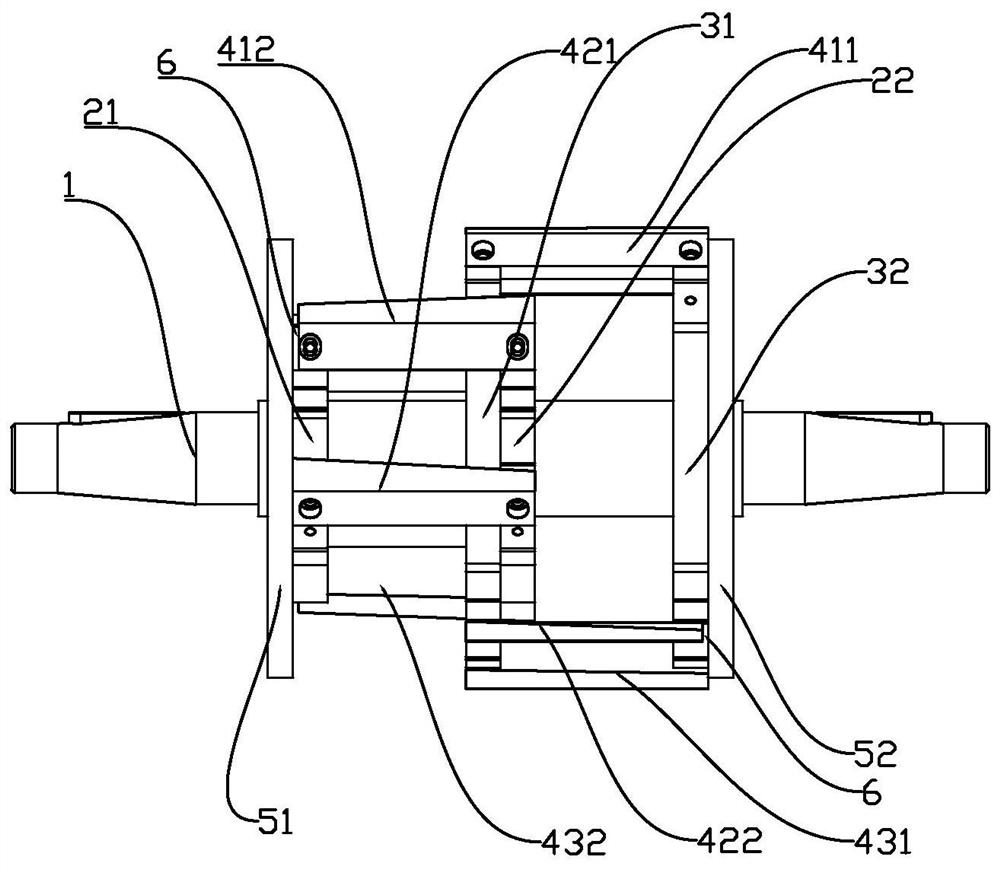

[0035] A cutter shaft of a crusher includes a main shaft 1 on which a front end baffle 51 and a rear end baffle 52 are arranged and correspondingly arranged at both ends of the main shaft 1 . On the main shaft 1, between the front end face baffle plate 51 and the rear end face baffle plate 52, the front one tool rest 21, the rear one tool rest 31, the front two tool rests 22 and the rear two tool rests 32 are arranged respectively in sequence. Such as figure 1 , 2 As shown, the rear one tool rest 31 and the front two tool rests 22 are overlapped and arranged in the middle of the main shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com