Shaft coupling of mechanical supercharger

A technology of mechanical superchargers and couplings, applied in couplings, elastic couplings, mechanical equipment, etc., can solve the problem of shortening the fatigue life of coupling torque springs, and solve the grooves on the inner surface of the torque springs. Influence of notches, effect of reducing wear, avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

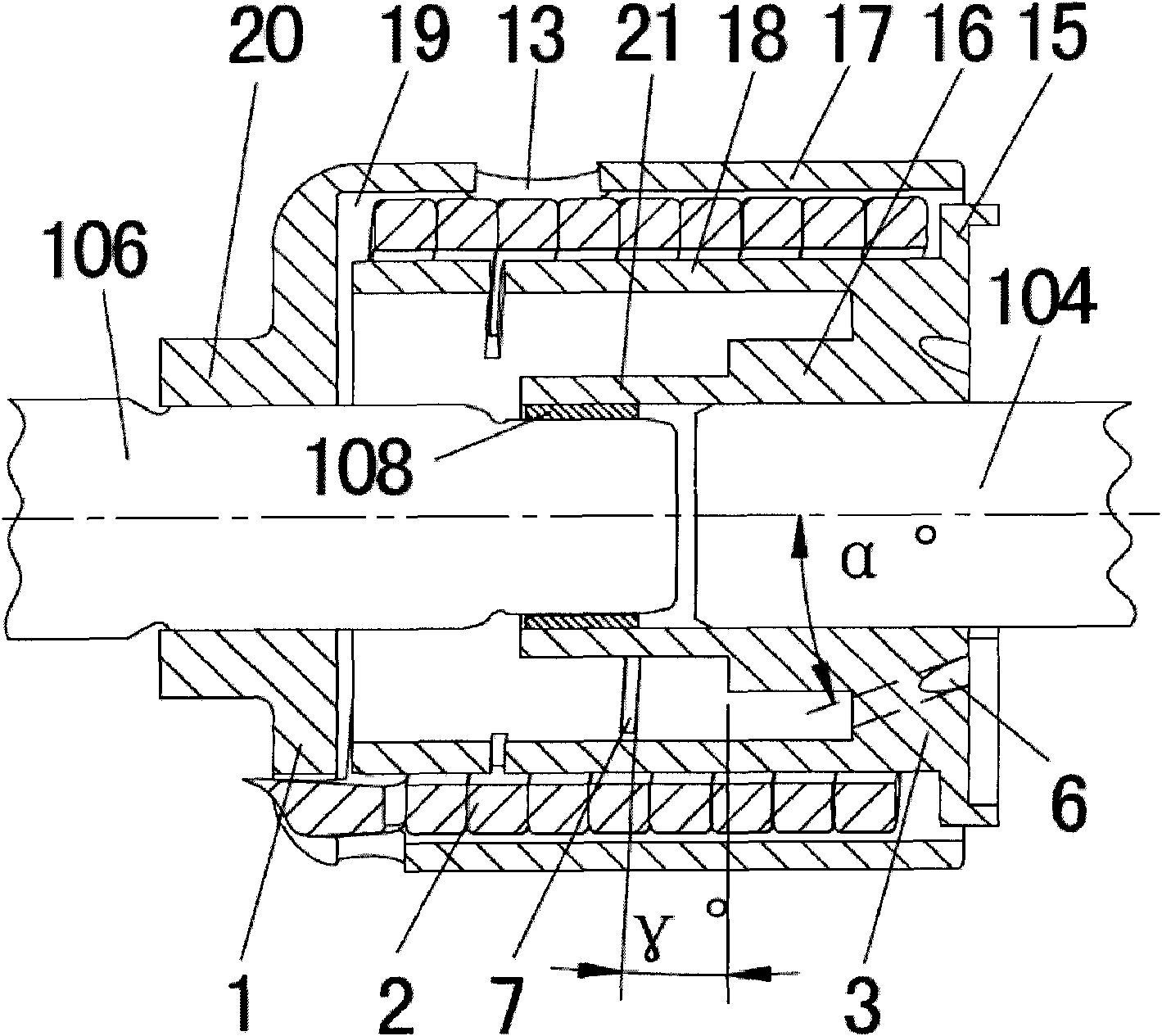

[0033] In the following, referring to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape and structure of each component involved, the mutual position and connection relationship between each part, the function and working principle of each part, etc. will be further described. Details of:

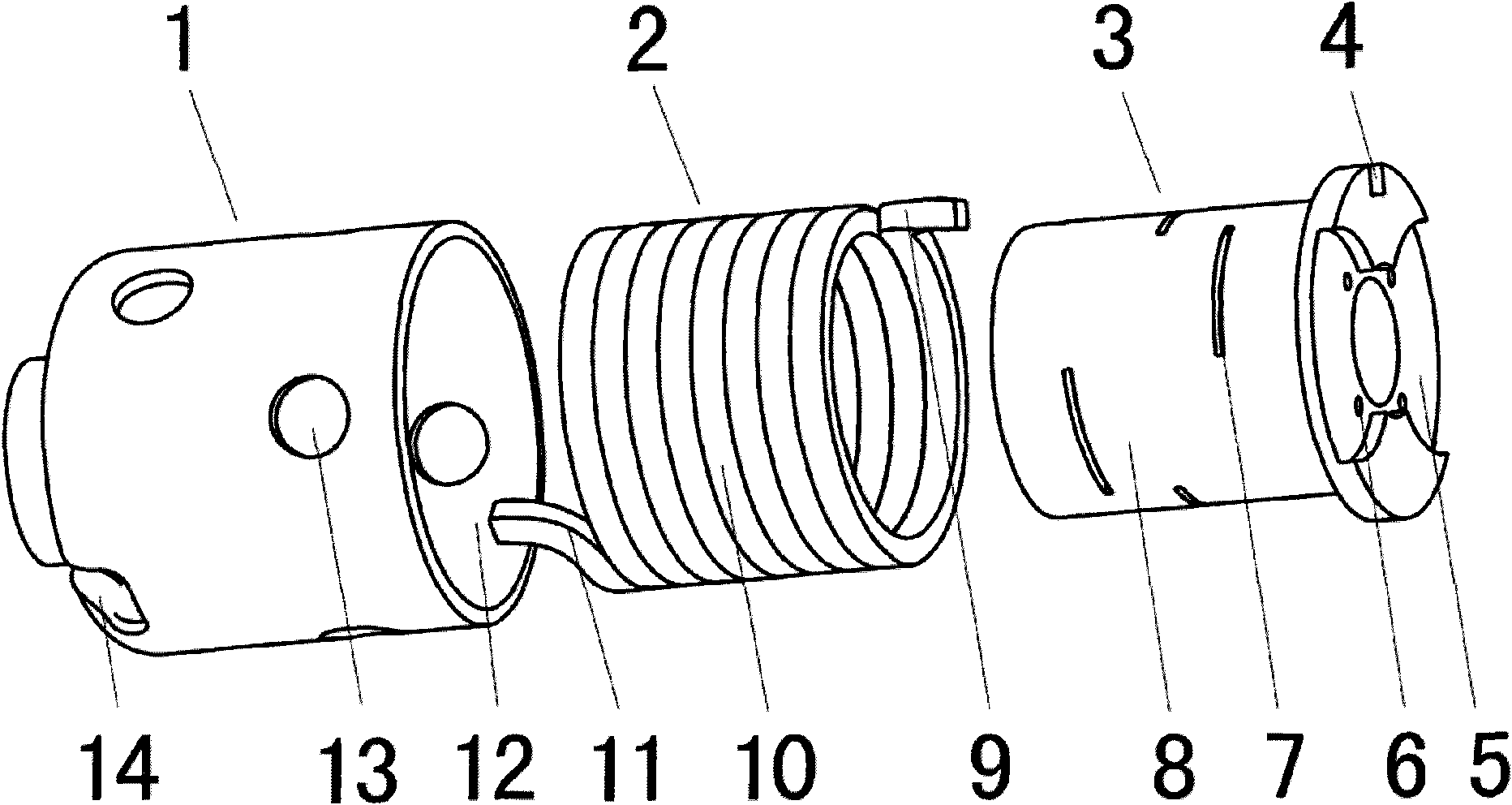

[0034] as attached figure 1 As shown, the present invention is a coupling of a supercharger, and the coupling of the supercharger includes a front hub 1, a torsion spring 2, a rear hub 3, a rear notch 4, and a rear tang 9. , the front tang 11, the front slot 14, the front hub 1 is set to a columnar cavity structure, the rear hub 3 is set to a columnar structure, the annular torsion spring 2 is set outside the rear wheel hub 3, and the rear wheel hub 3 is set in the In the front hub 1 , the front tang 11 of the torque spring 2 is clamped on the front notch 14 on the front hub 1 , and the rear tang 9 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com