A high-efficiency knife shaft applied to a film crusher and its crusher

A crusher and high-efficiency technology, applied in the direction of grain processing, etc., can solve problems such as material jam, low efficiency, and reduced efficiency, and achieve the effects of low noise, good cutting effect, and improved life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

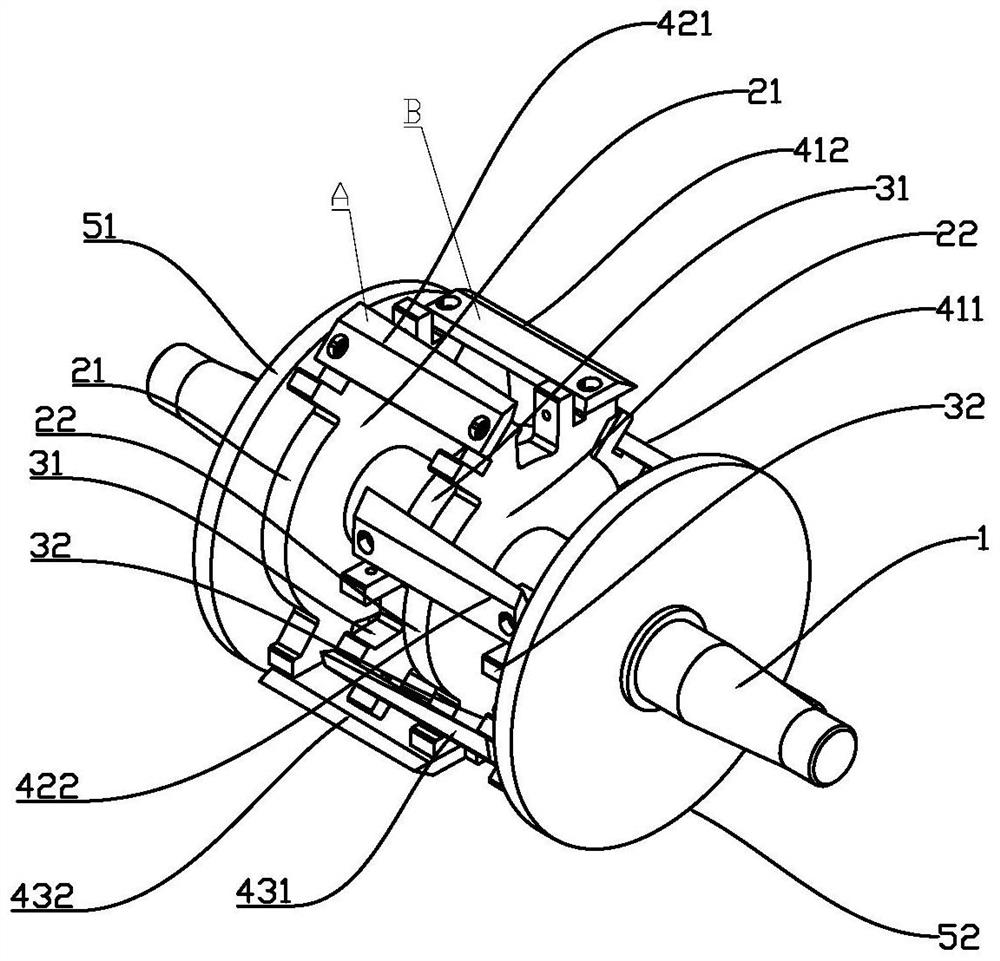

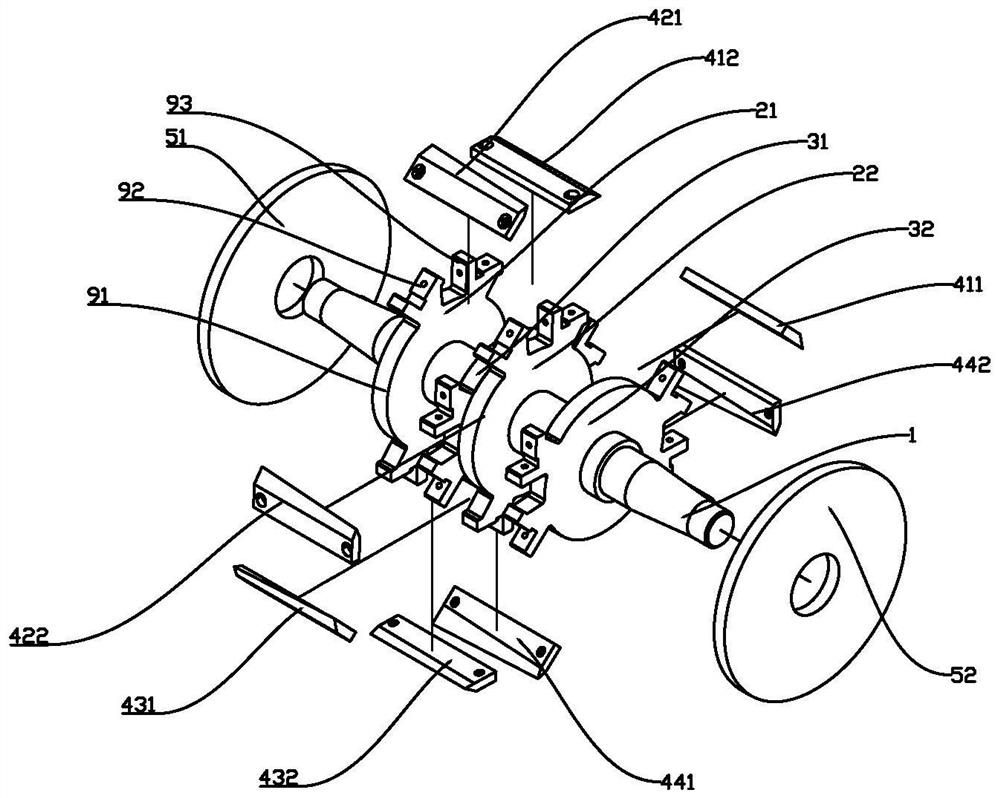

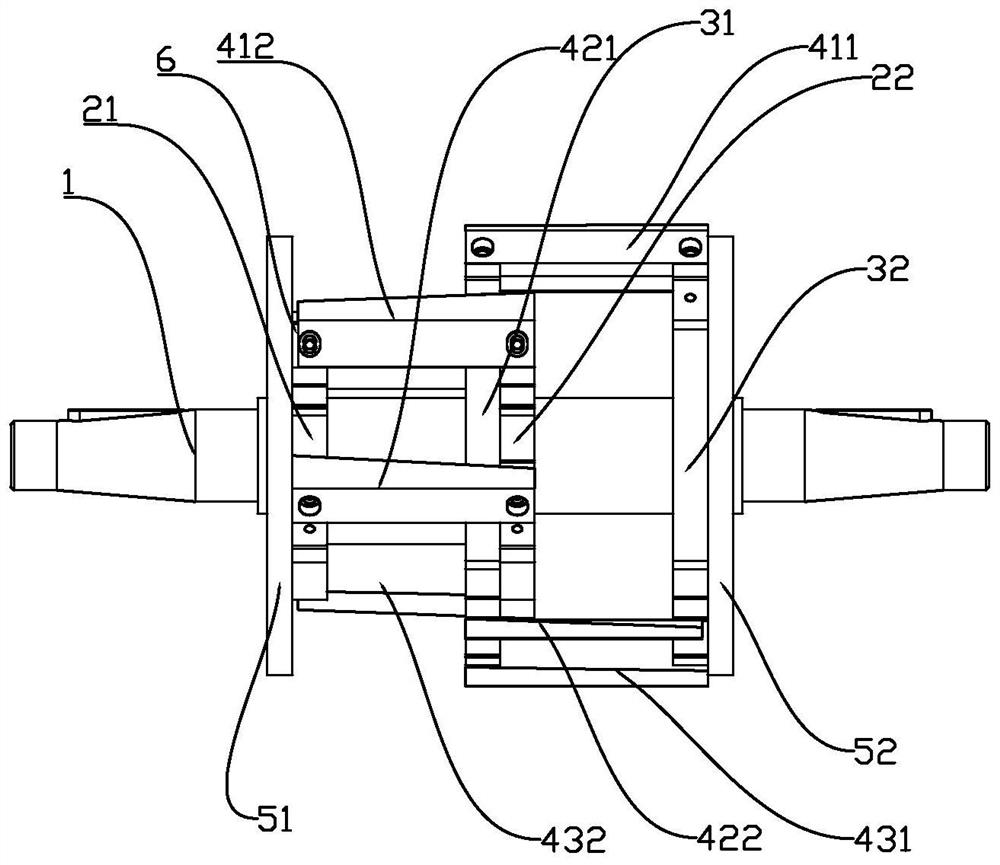

[0032] Below in conjunction with accompanying drawing and embodiment, the present invention is described in detail:

[0033] In order to deepen the understanding of the present invention, the present invention will be further described in detail below with reference to the implementation cases and accompanying drawings. The present invention can be implemented in the following ways:

[0034] The tool shaft in this case includes a rotating spindle, a tool holder, an end face baffle and a special-shaped knife. Among them, the main shaft is the main carrier of the special-shaped knife, which is segmented in order in the axial direction, and the order is: input flywheel installation section, bearing installation section, working section, bearing installation section, and counterweight flywheel installation section to form a complete cutter shaft . While ensuring the workload, only two rows of knives are installed in the axial direction between the front baffle 51 and the rear ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com