Automatic directional oiling mechanism for screw

A technology of oiling and screwing, which is used in coatings, devices that apply liquid to the surface, etc., can solve the problems of screw threads stained with grease, secondary rework, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

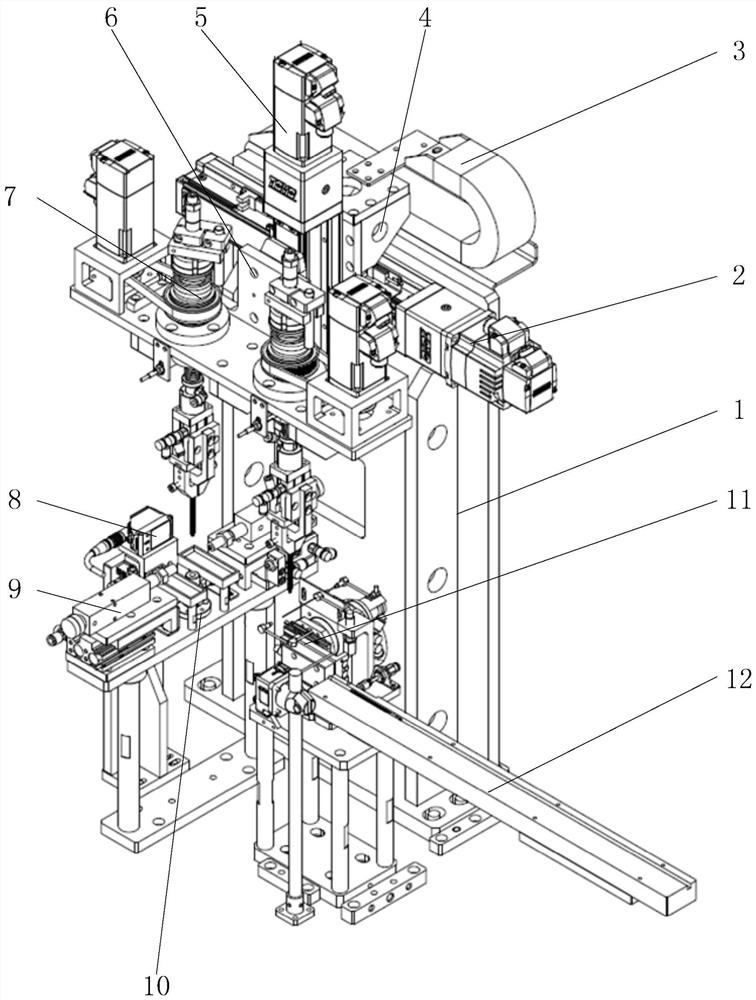

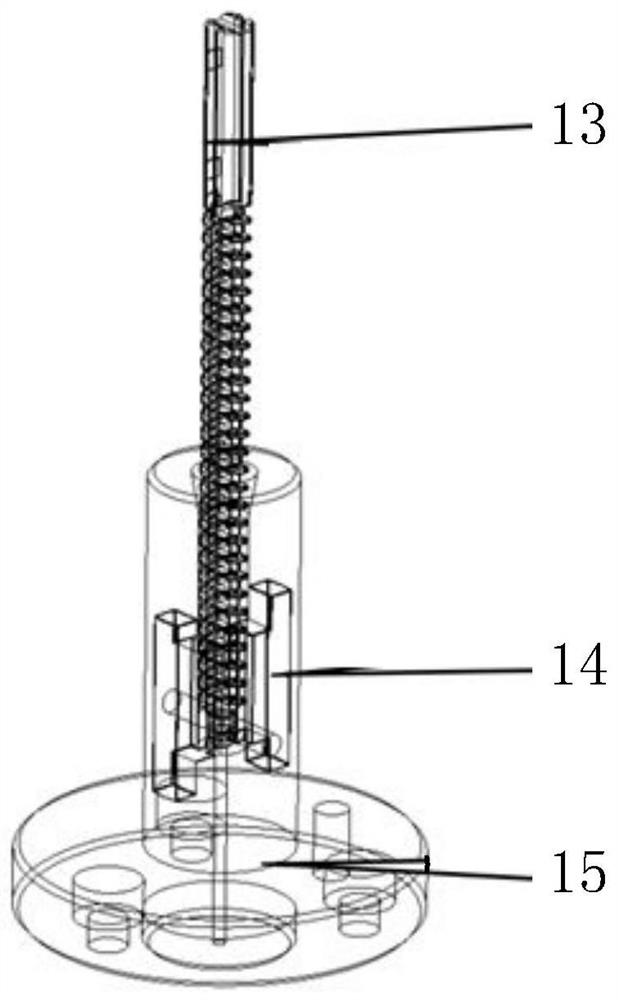

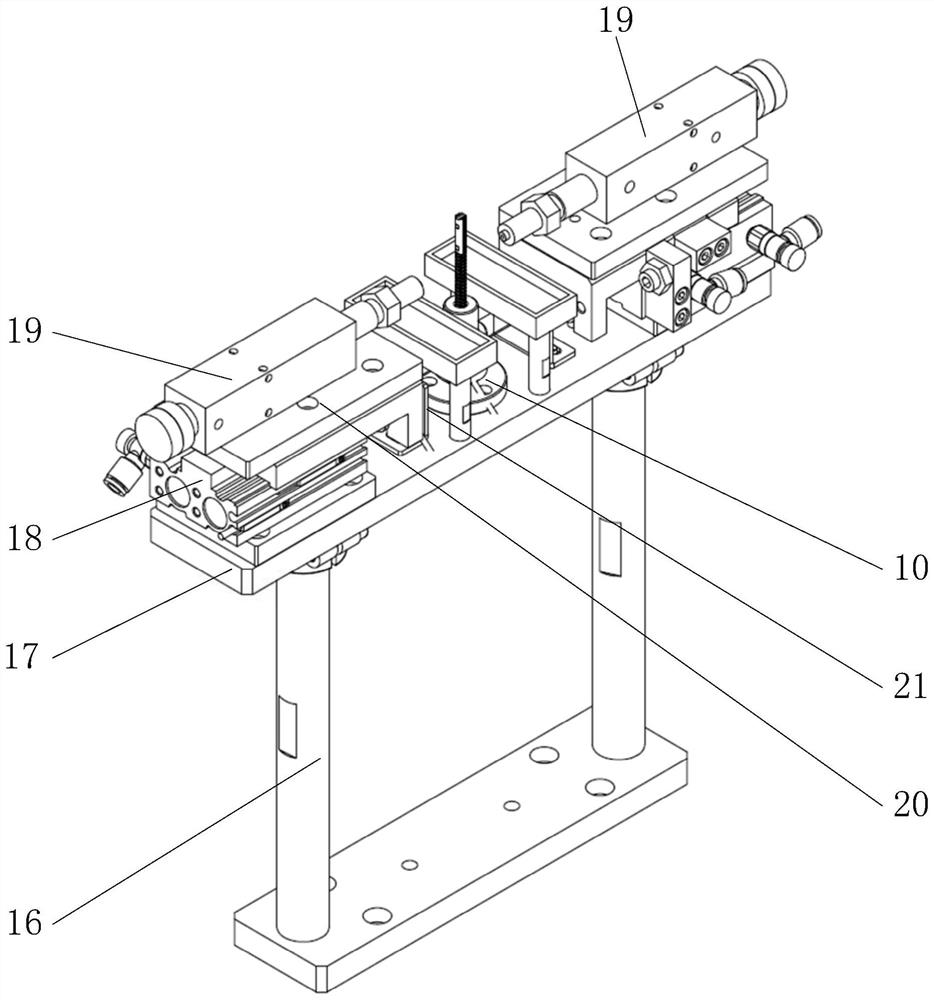

[0057] like Figure 1 to Figure 9 shown,

[0058]An automatic directional oiling mechanism for a screw, including an equipment base 1, a clamping and rotating mechanism 7, an oiling detection mechanism 8, a quantitative oiling mechanism 9, a screw material distribution mechanism 11 and a feeding track 12. The equipment base 1 is along the It is arranged in the Z-axis direction, and the top side of the device base 1 is provided with an X-axis drive motor 2 along the X-axis direction. The top of the X-axis connection seat 4 is connected with the Z-axis drive motor 5, and the driving end of the bottom of the Z-axis drive motor 5 is drivingly connected to the Z-axis connection seat 6 through the Z-axis slider. The clamping and rotating mechanism 7 arranged in the direction is connected, and a quantitative oiling mechanism 9 is arranged below the clamping and rotating mechanism 7 along the negative direction of the X-axis. There is an oiling detection mechanism 8, and a screw fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com