Military equipment overturning test device

A testing device and equipment technology, applied in weapon testing, offensive equipment, weapon accessories, etc., can solve the problems of inability to guarantee the quality, heavy weight, and long test cycle of weapon system products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

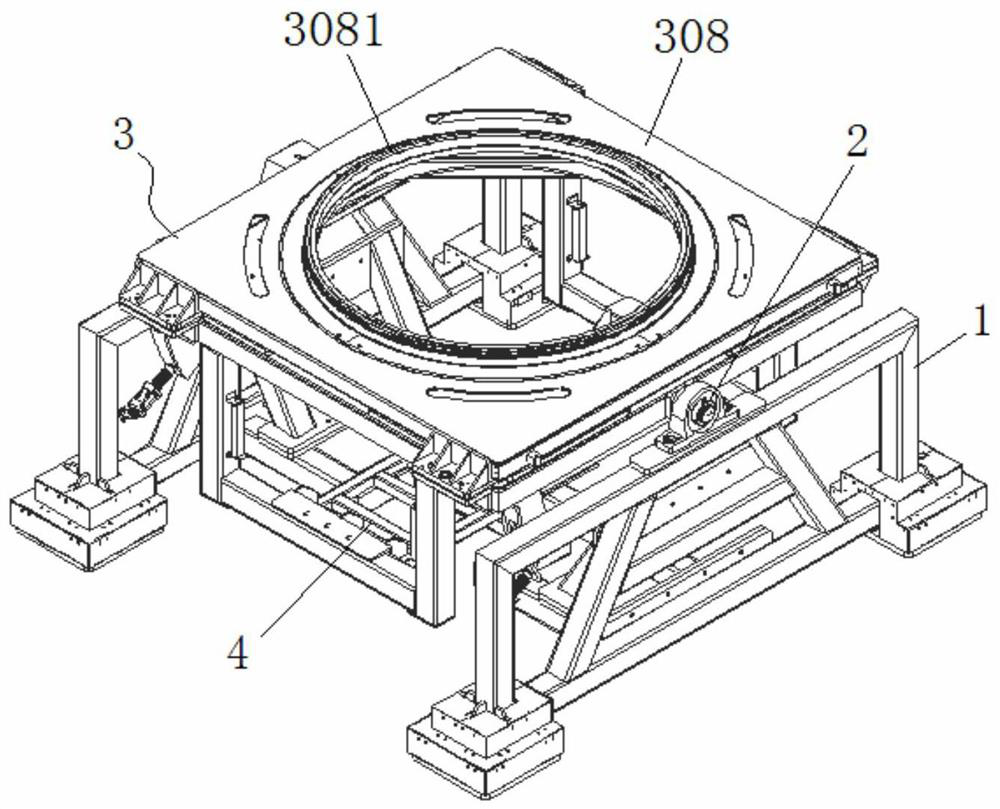

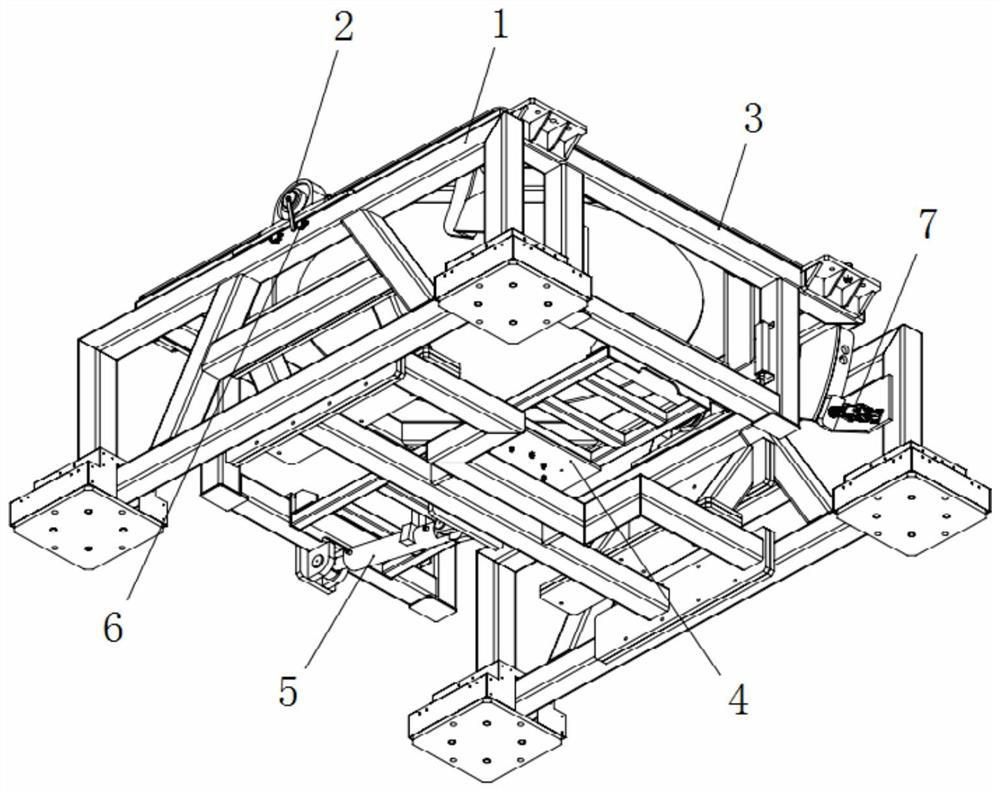

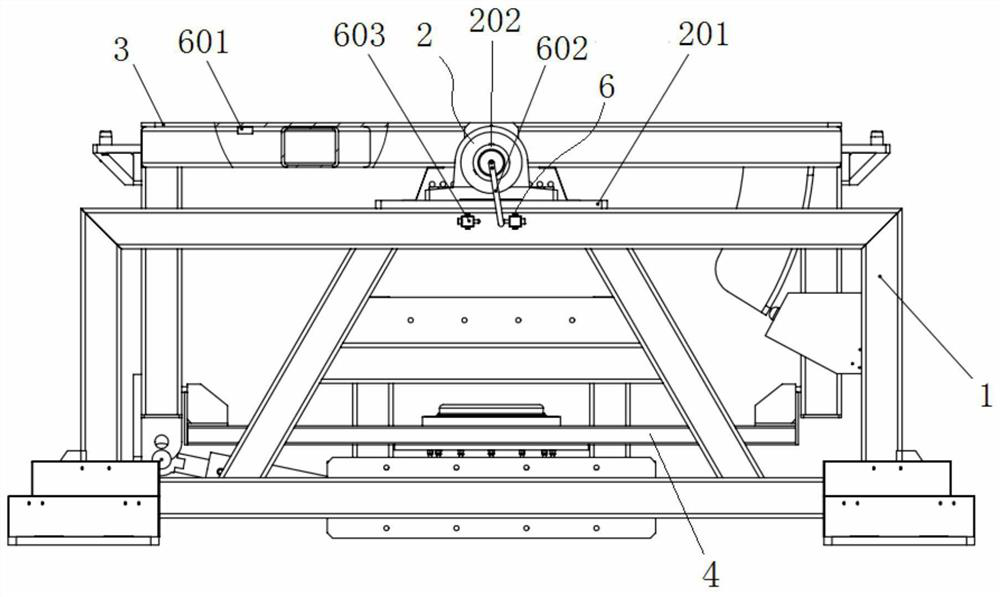

[0035] Such as Figure 1-12 As shown, the present invention includes a test base 1, an overturn frame 3, an overturn driving device 5, a position detection assembly 6 and a locking assembly 7, wherein the test base 1 includes side supports 101 on the left and right sides, and the two sides of the overturn frame 3 The middle part is rotatably mounted on the side brackets 101 on the corresponding sides, the bottom end of the turning drive device 5 is hinged to the bottom of the test base 1, and the upper linear output end is hinged to one end of the turning frame 3, and the turning frame 3 passes through The turning drive device 5 is driven to turn over in the test base 1, and the upper side edge of the turning frame 3 is provided with a support plate 307 with a positioning pin 306, and the positioning pin 306 is used to fix a tray 308 of different types of mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com