Electric vehicle hub motor combining external rotation type and internal rotation type

An in-wheel motor and internal rotation technology, which is applied to synchronous motors with stationary armatures and rotating magnets, electric vehicles, motors, etc., can solve the problem of high replacement costs, high manpower and material resources, and the economic burden of electric vehicle users. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

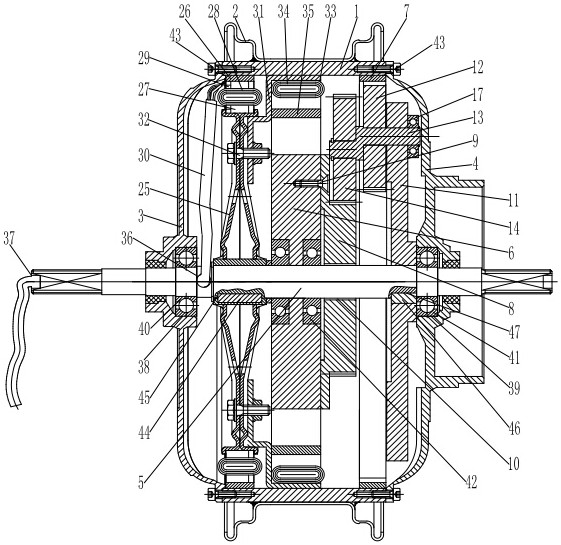

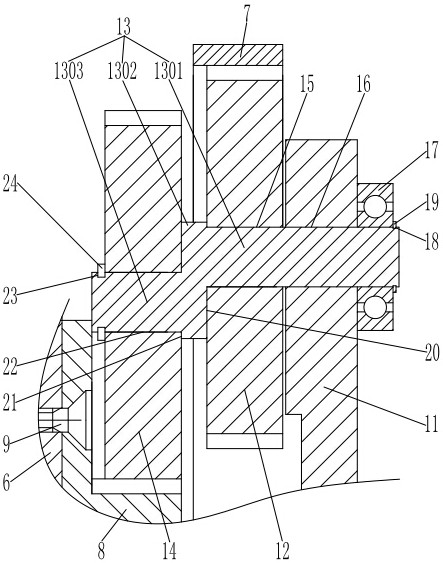

[0020] see figure 1 , figure 2 , the present invention provides an electric wheel hub motor combining an external rotation type and an internal rotation type, comprising a steel ring 1, a wheel hub 2 set outside the steel ring 1, the left end port cover of the steel ring 1 is combined with a motor left cover 3 The right end port of the steel ring 1 is covered with a motor right cover 4; the center of the steel ring 1 is provided with a motor shaft 5; Outside the right cover 4 of the motor; the left part of the steel ring 1 is provided with a main motor stator assembly that matches the motor shaft 5; the main electronic stator assembly is connected with an electric wire 30, and the electric wire 30 passes through to the outside world; The right side of the stator assembly of the main motor is provided with a generator stator assembly fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com