Self-adaptive brush assembly and door leaf full-automatic dust removal system comprising same

A dust removal system and self-adaptive technology, applied in the direction of dust removal, cleaning methods using tools, cleaning methods using gas flow, etc., can solve problems such as poor effect, easy to cause dust, and low dust cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

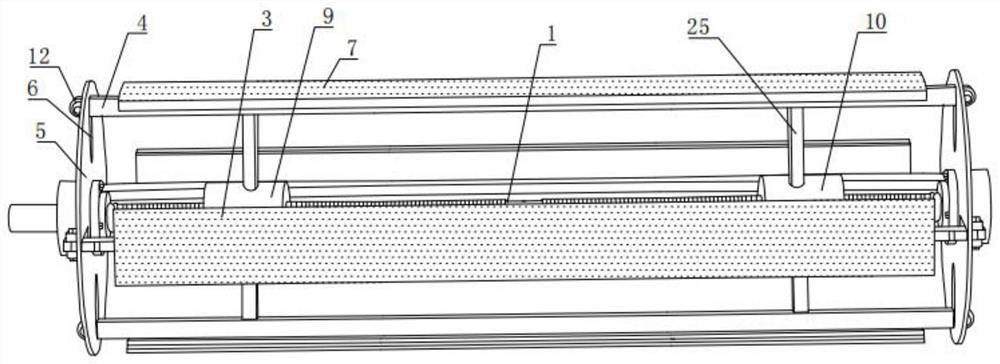

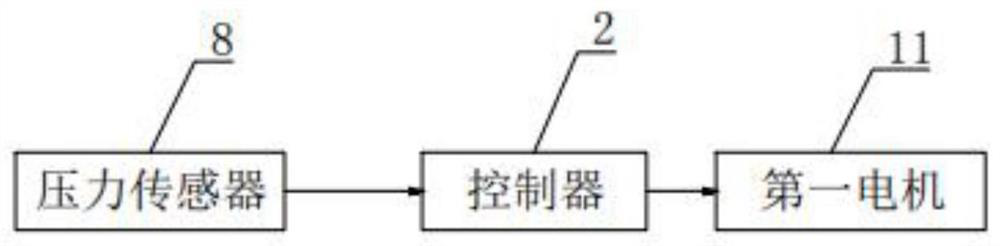

[0035] Such as figure 1 with figure 2 As shown, an adaptive brush assembly includes a lead screw 1, a controller 2, four movable tiles 3, four limit rods 4 and limit circular plates 5 respectively arranged at both ends of the lead screw 1;

[0036] Four limit grooves 6 are evenly distributed on the limit circular plate 5, the end of the limit rod 4 is slidingly fitted with the limit groove 6, and the limit rod 4 is in phase with the movable tile 3. connected, the surface of the movable tile 3 is provided with a brush 7, and a pressure sensor 8 is provided between the brush 7 and the movable tile 3;

[0037] The front section and the rear section of the lead screw 1 are respectively provided with a first helical groove and a second helical groove opposite in direction of rotation, and the front section and the rear section of the lead screw 1 are respectively provided with a first nut seat 9 and a corresponding one. The second nut seat 10; the first nut seat 9 and the second...

Embodiment 2

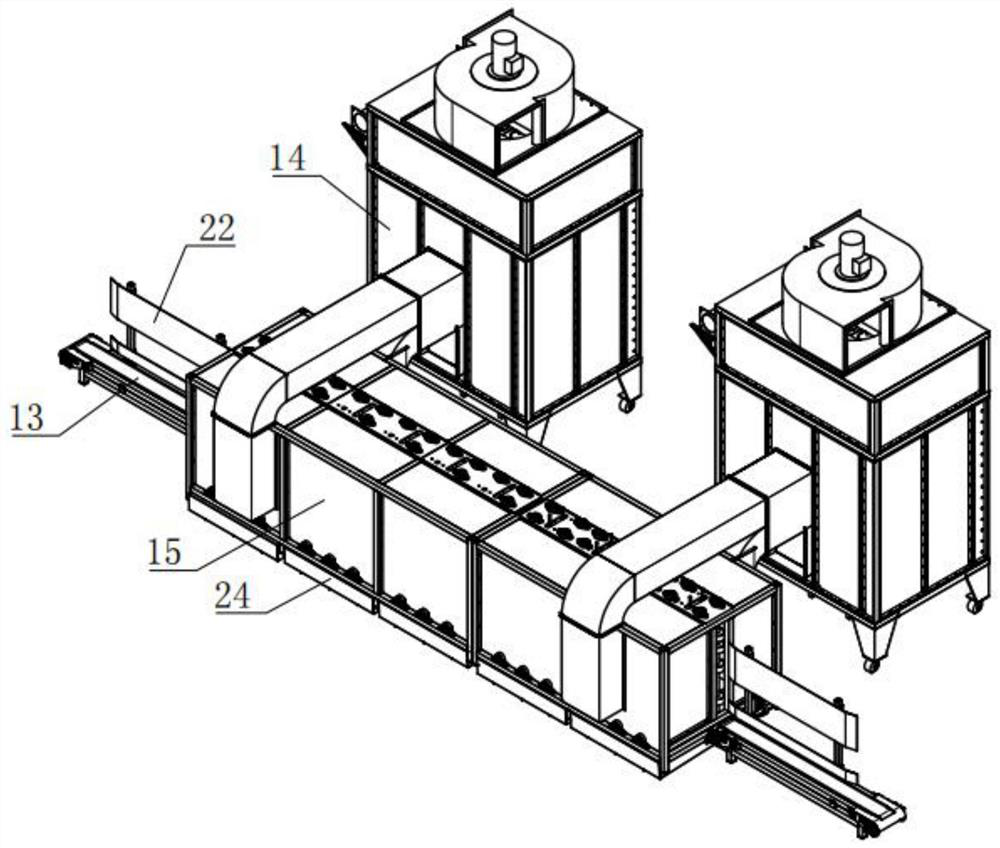

[0046] Such as Figure 1-7 As shown, this embodiment is a fully automatic dust removal system for a door leaf that includes the self-adaptive brush assembly 16 in Embodiment 1, including a feeding mechanism 13, a dust suction mechanism 14 and a plurality of dust removal units 15; the brush assembly 16 has two groups;

[0047] The dust removal unit 15 includes a dust removal box 17, two sets of stoppers 18 and two sets of dust removal air knives 19, the centers of the opposite sides of the dust remover box 17 are respectively provided with openings for door leaves to enter and exit, and each set of stoppers 18 It consists of a plurality of driving wheels 20 arranged along the length direction of the dust removal box 17. Two sets of limiters 18, two sets of brush assemblies 16 and two sets of dust removal air knives 19 are connected to the dust removal box 17 respectively. Limiting parts 18, two groups of brush assemblies 16 and two groups of dedusting air knives 19 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com