Self-adaptive control method for stability and roundness of radial and axial rolling process of super-large rings

A self-adaptive control and axial rolling technology, applied in the field of ring rolling, can solve the problems of ring geometry variation, product quality at the end of ring rolling, roundness and stability control of super-large ring rolling, etc. problems, to achieve the effect of both stability and roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

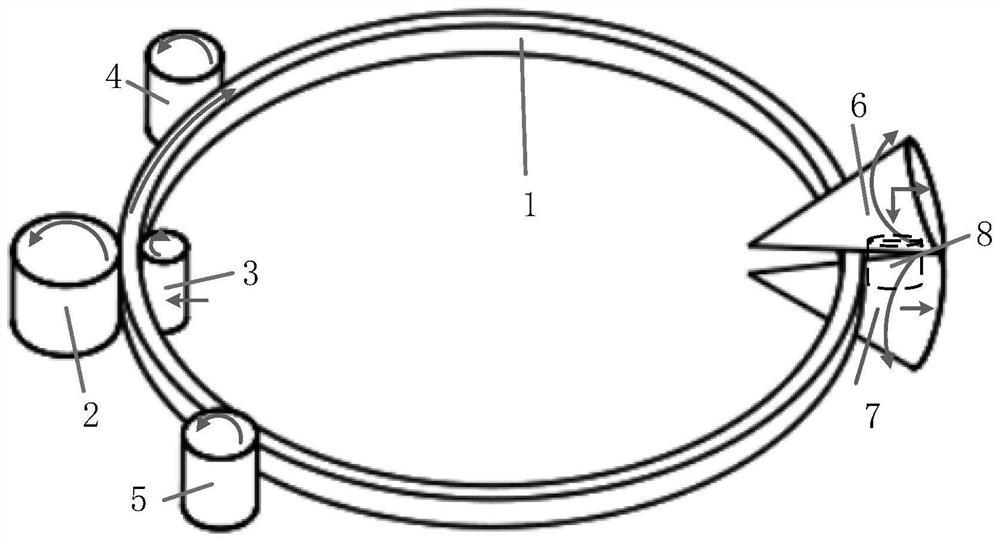

[0066]

[0070]

[0072]

[0074] n=n

[0076]

[0079]

[0081]

[0083]

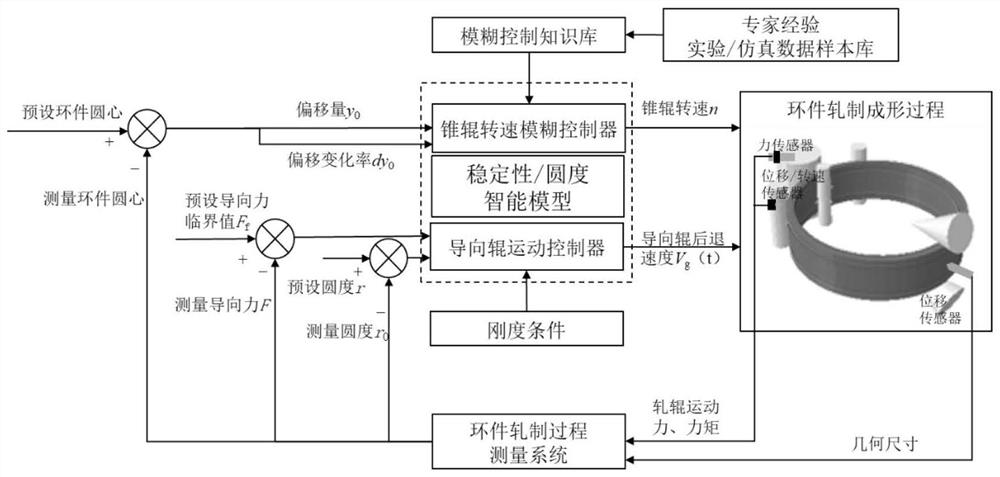

[0086] The guiding force has a significant impact on the rolling roundness of the ring. Therefore, the guiding force feedback control strategy as shown in Figure 6 is proposed.

[0087]

[0089] F

[0090]

[0093]

[0095] V

[0097]

[0100]

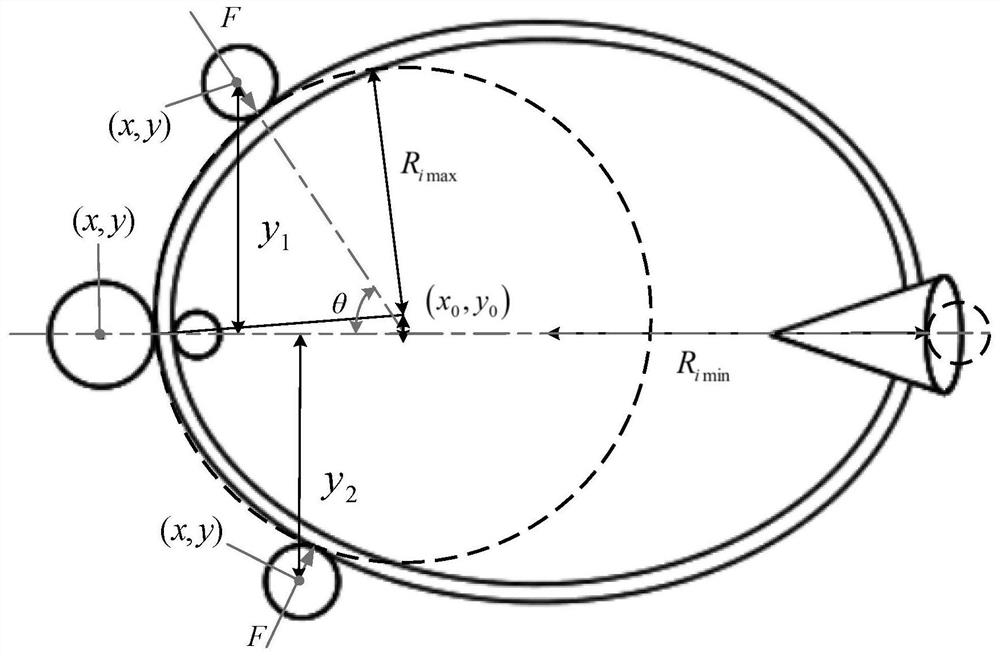

[0104] Further analyzed the average offset of the whole process of ring rolling and the later stage of rolling (the ring was rolled from Φ15m to the end)

[0105] As shown in FIG. 12 , the ring has always maintained a positive offset (downward biased state), and the rate of change of the offset changes only within a small range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com