Adjustable machining workbench

A technology of mechanical processing and workbench, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., and can solve the problems of lower processing error tolerance rate and affecting processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

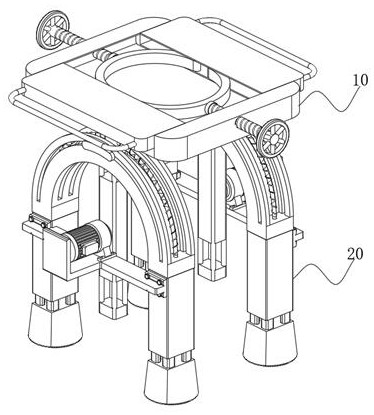

[0044] see Figure 1-Figure 10 As shown, this embodiment provides an adjustable mechanical processing workbench, including a processing platform 10 and a pair of support mechanisms 20 installed at the bottom of the processing platform 10, and the processing platform 10 at least includes:

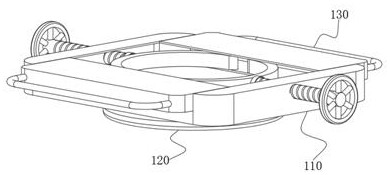

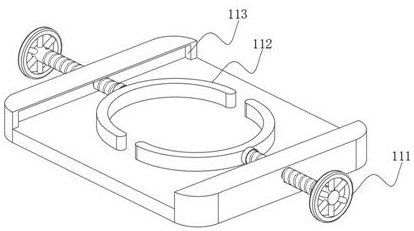

[0045] The operation panel surface 110, both sides of the operation panel surface 110 are provided with adjustment rods 111, the adjustment rods 111 are rotationally connected with the operation panel surface 110, and the end of the adjustment rod 111 is provided with a clamping rod 112;

[0046] Rotation mechanism 120, the rotation mechanism 120 is arranged at the bottom end of the operation panel surface 110, the rotation mechanism 120 includes a turntable 121, the middle position of the turntable 121 is provided with a rotating shaft 122, and the rotation shaft 122 is connected with the bottom end of the operation panel surface 110;

[0047] The support mechanism 20 includes at least:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com