Automatic modification equipment for front edge of fan blade

A technology for fan blades and blade leading edges, which is applied in the field of automatic repair equipment for the leading edge of fan blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

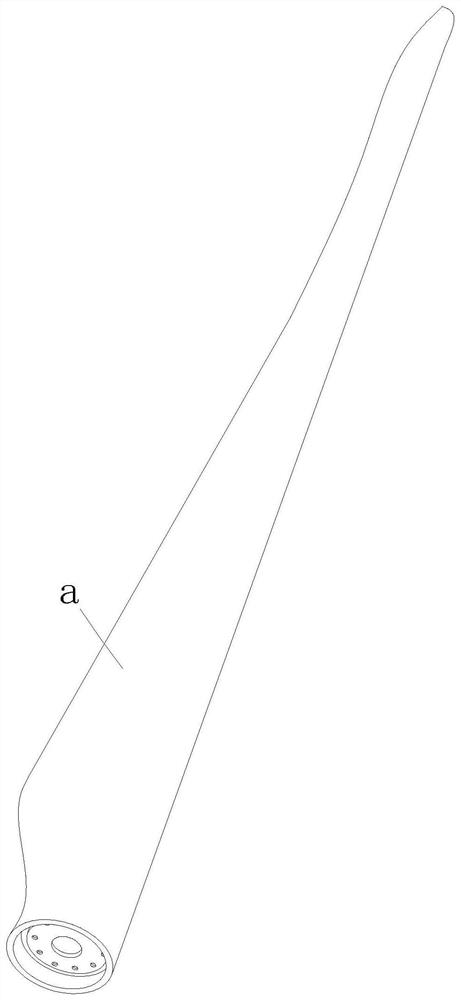

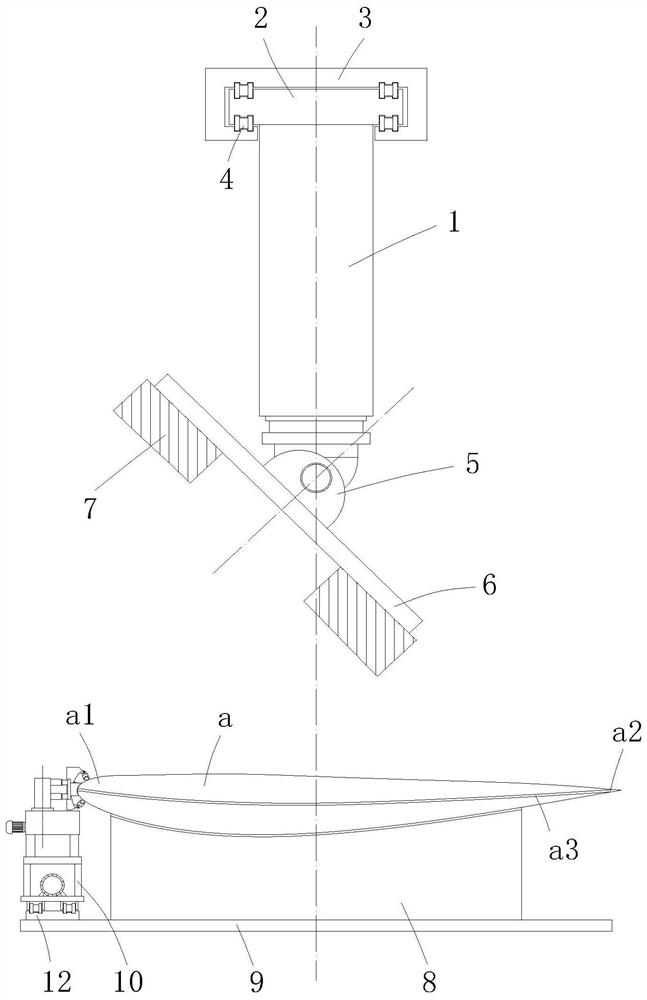

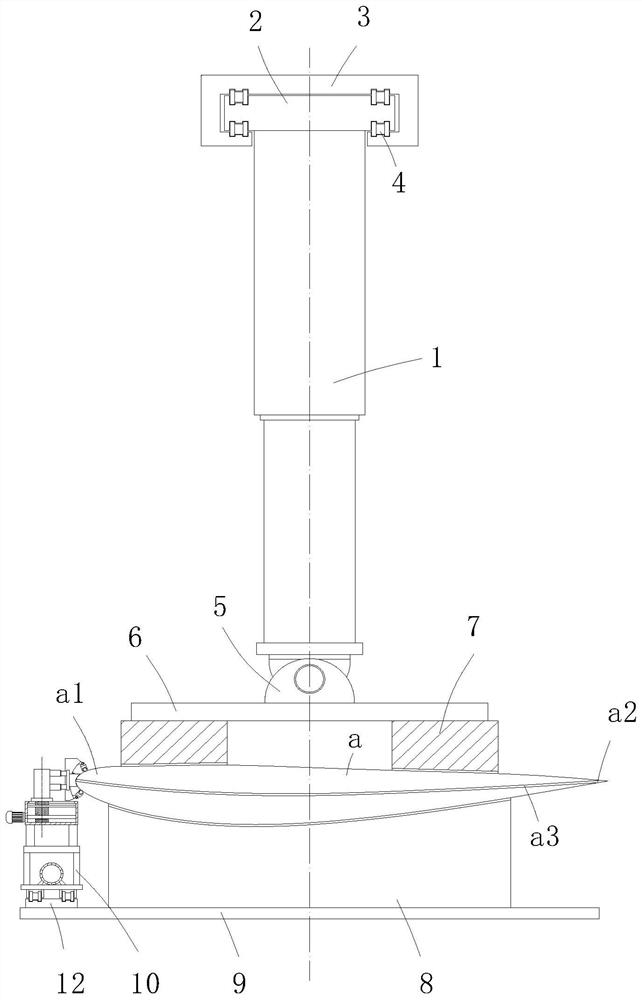

[0030] A leading edge automatic trimming device for fan blades, comprising a support platform 8 for laterally supporting the fan blade a and a base 9 for fixing the support platform 8 to the ground, above the support platform 8 there is a matching support The platform 8 is used to position the upper positioning unit of the fan blade a, and the upper end of the base 9 is laid with a trolley track 12 on the side close to the leading edge a1 of the blade, and the trolley track 12 is provided with a front edge repair mechanism that can drive independently;

[0031] In this example, if Figure 1-2 As shown, the cross-section of the fan blade a shows that the fan blade a includes two sheets and an adhesive layer a3 that is located between the two sheets and bonds the two sheets. After the fan blade a is bonded and formed, the adhesive The junction layer a3 will protrude on the leading edge a1 and the trailing edge a2 of the fan blade a after the mold is opened, and it needs to be re...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is that, as Figure 2-3 As shown, the upper positioning unit includes an underpackage walking track 3 fixed on the crossbeam of the workshop, and a self-propelled linear walking vehicle 2 is installed through the walking wheels 4 in the walking track 3. The lower end of the linear walking vehicle 2 is vertically A lifting cylinder 1 is installed, and the telescopic end of the lifting cylinder 1 is connected with a horizontally arranged installation platform 6 through a rotating seat 5. The lower end of the installation platform 6 is provided with a positioning seat 7 for positioning the fan blade a after cooperating with the support platform 8, and the lifting cylinder 1 A pressure sensor II is installed on the telescopic end of the motor, and the movement of the positioning seat 7 can be effectively driven by the walking of the linear traveling vehicle 2 on the walking track 3, and the segmented blade leading edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com