Automatic running-in system and method for power transmission grade high-voltage vacuum circuit breaker

A vacuum circuit breaker, high-voltage technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve problems such as impact, large vibration of the circuit breaker body, and inability to use normal working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

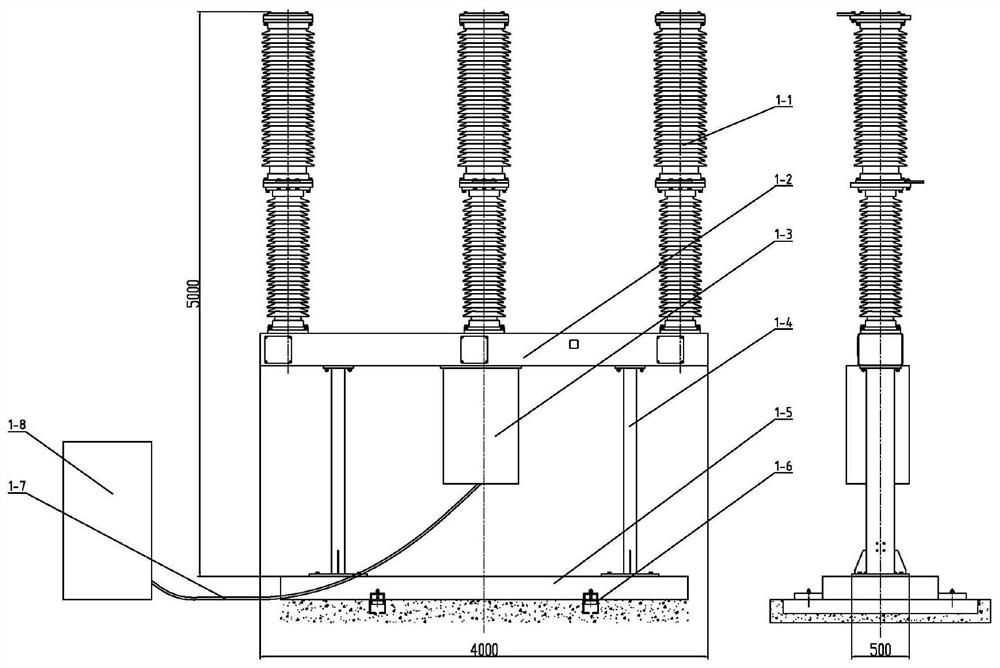

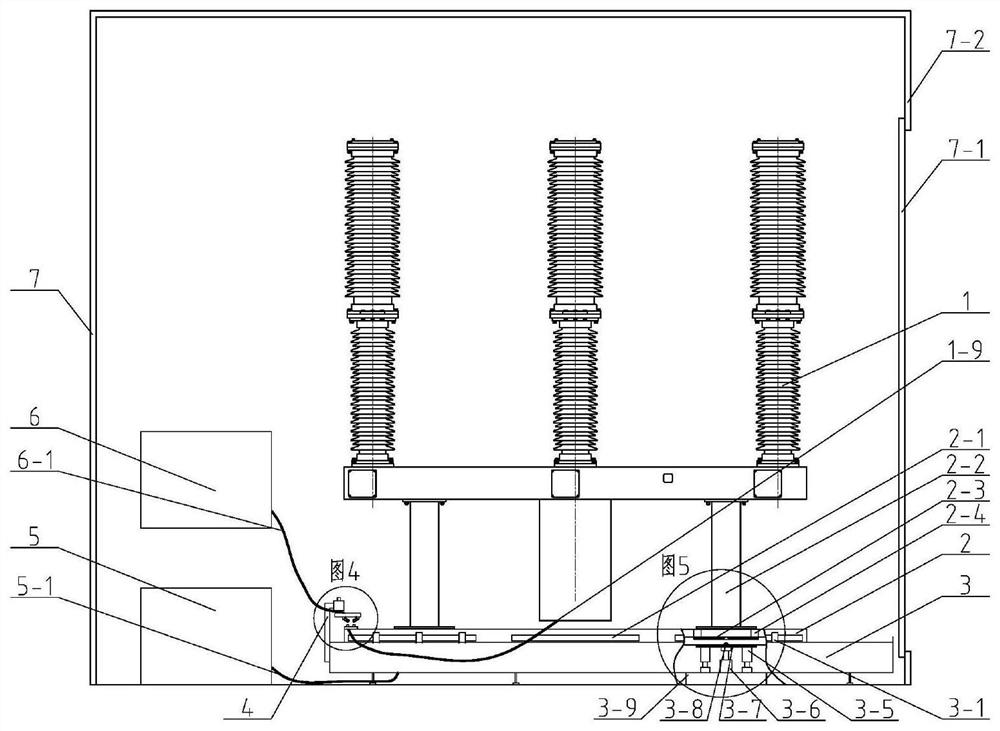

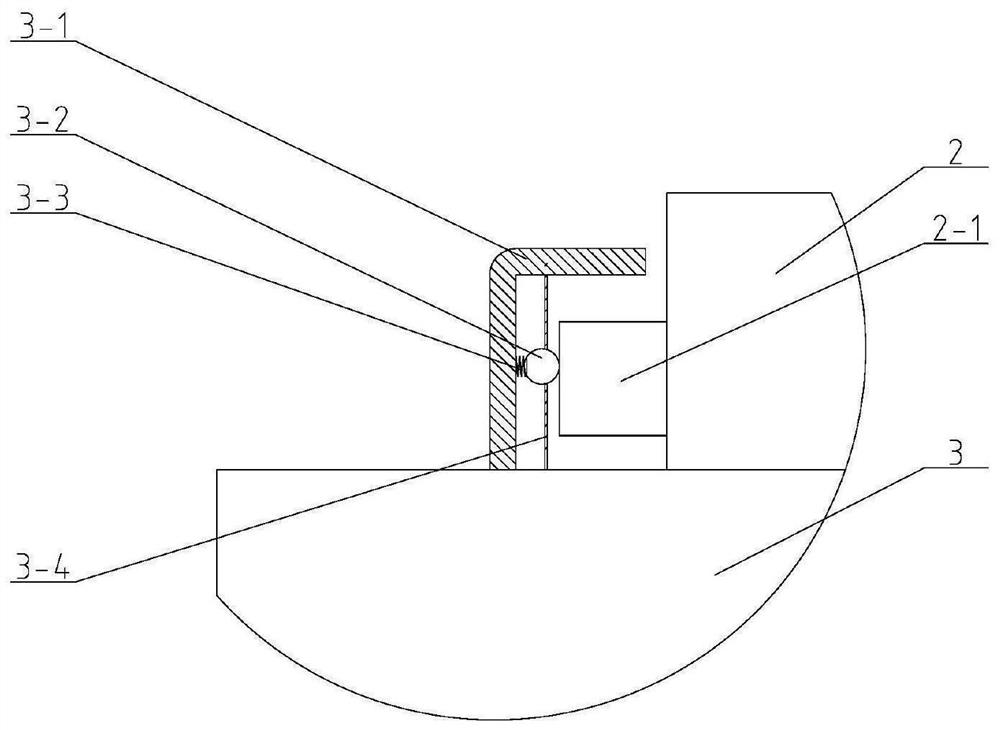

[0048]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0049] It is an object of the present invention to provide an automatic milling system and method for transmitting a transmission level high-voltage vacuum circuit breaker, which is capable of improving the operation of the transmission of the transmission level high-voltage vacuum circuit breaker, and guarantees the personal safety during the test.

[0050] In order to make the above objects, features, and advantages of the present invention, the present invention will be further described in detail below with reference to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com