A Digital Constant Power High Voltage Plasma Power Supply

A plasma, constant power technology, applied in output power conversion devices, AC power input into DC power output, electrical components, etc. , low power efficiency, etc., to facilitate mass production, improve anti-interference ability, and ensure the uniformity of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

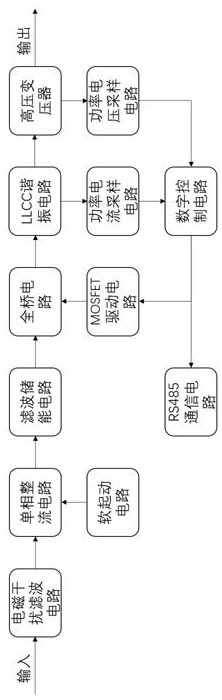

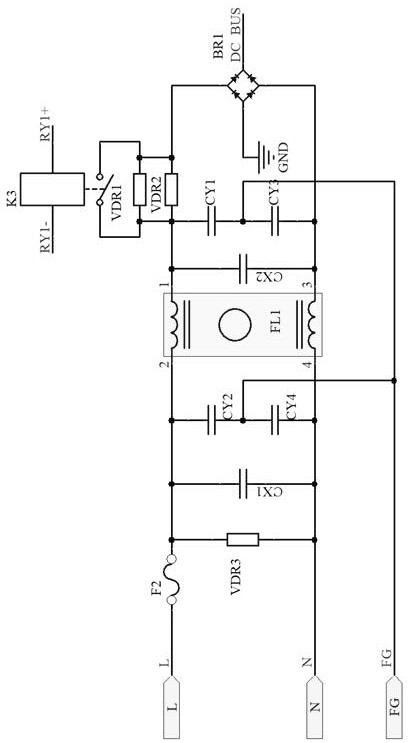

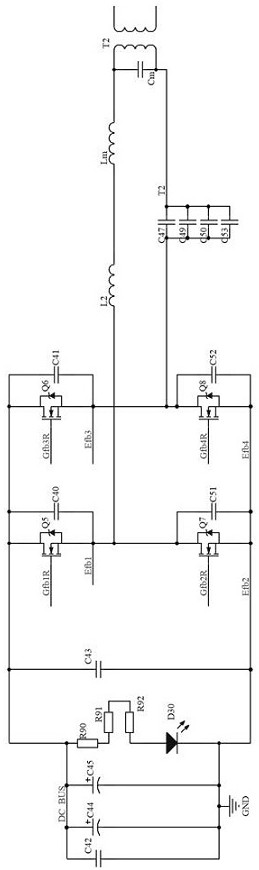

[0024] Example 1: see Figure 1-Figure 6 , a digital constant power high-voltage plasma power supply, the digital constant power high-voltage plasma power supply includes an electromagnetic interference filter circuit, a soft start circuit, a single-phase rectifier circuit, a filter energy storage circuit, a full bridge circuit, an LLCC resonance circuit, and a power voltage Sampling circuit, power and current sampling circuit, digital control circuit, MOSFET drive circuit and RS485 communication circuit, the input voltage is connected to the single-phase rectifier circuit through the electromagnetic interference filter circuit, a DC voltage is formed by the filter energy storage circuit, and connected to the full bridge circuit wave, and then connected to the LLCC resonant circuit for oscillation filtering, and then connected to the high-voltage transformer for output; the soft start circuit is connected to the single-phase rectifier circuit, the power voltage sampling circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com