A mold for orthopedic metal parts

A technology for metal parts and orthopedics, which is applied in the field of metal orthopedic molds, which can solve the problems of lack of cleaning function and difficulty in ensuring the flattening of copper strips, so as to improve the efficiency of orthopedics, prevent elastic recovery, and ensure the effect of orthopedics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

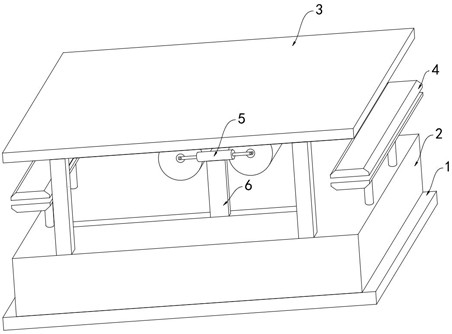

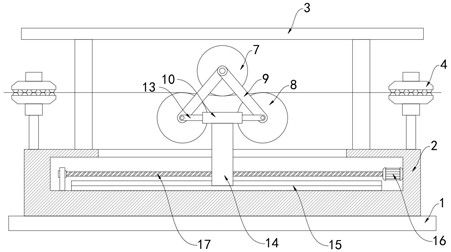

[0029] Such as Figure 1-8 As shown, a mold for orthopedic metal parts includes a base plate 1, a base 2 is fixed on the base plate 1, a top plate 3 is arranged above the base 2, and fixing clips 4 are arranged on both ends of the upper surface of the base 2, for use To fix the two ends of the copper strip, an orthopedic mechanism 5 is arranged above the base 2, and a driving mechanism 6 for driving the orthopedic mechanism 5 to move is arranged in the base 2;

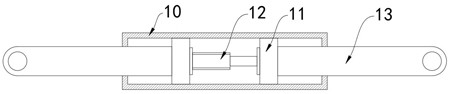

[0030] The orthopedic mechanism 5 comprises an upper orthopedic roller 7, the lower sides of the upper orthopedic roller 7 are provided with lower orthopedic rollers 8, the upper orthopedic roller 7 and the lower orthopedic roller 8 are connected by a connecting plate 9, and the two lower orthopedic rollers 8 A fixed cylinder 10 is provided, and two sliding plugs 11 are slidably connected in the fixed cylinder 10, and the two sliding plugs 11 are connected by a cylinder 12, and the two sliding plugs 11 are respectively...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap