Steel structure box beam convenient to install and assembling method

An easy-to-install, box-shaped girder technology, applied to long-strip structural members, structural elements, truss-type structures, etc. for load-bearing, can solve the problems of time-consuming and labor-intensive installation, inconvenient installation, etc., and achieve easy separation and convenience Pull adjustment, fast and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

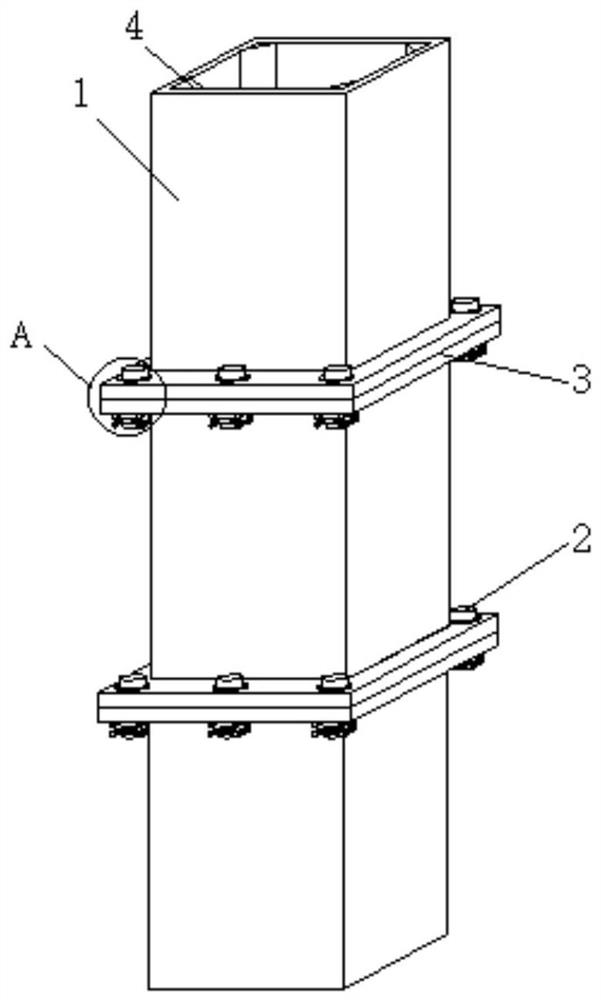

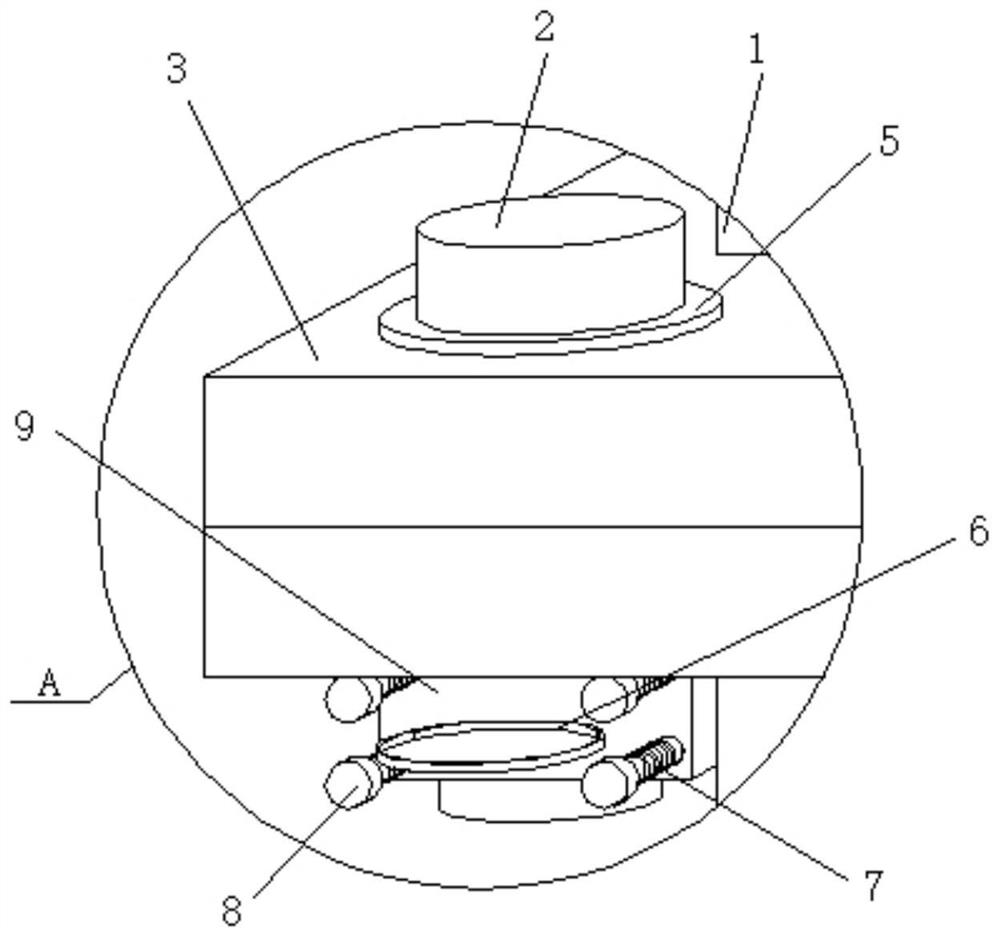

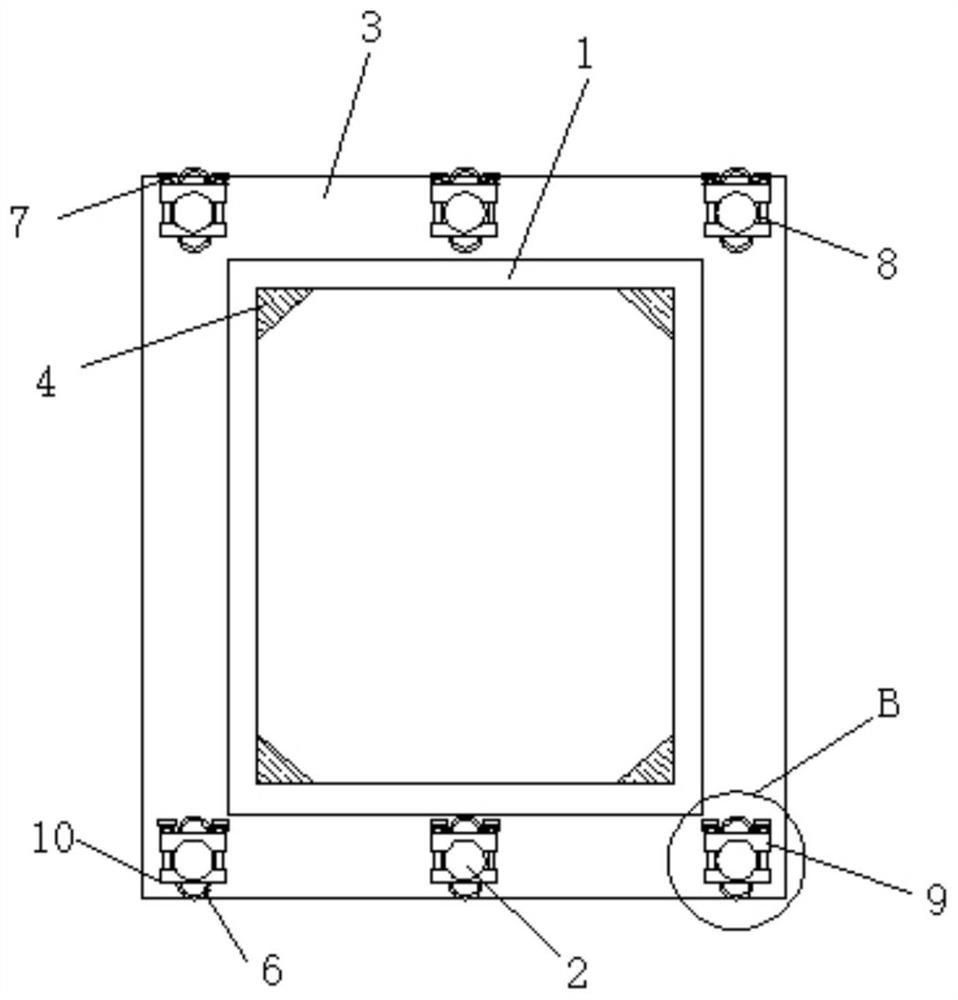

[0030] see Figure 1 to Figure 5 , the present invention provides a technical solution: a steel structure box girder for easy installation, including a box girder main body 1, an assembly frame 3 is sleeved on the end of the box girder main body 1, and the end face of the adjacent assembly frame 3 Fitting each other, the end surface of the assembly frame 3 is provided with an assembly hole, and the assembly column 2 runs through the inside of the assembly hole. Through the designed assembly column 2, assembly groove 12, assembly block 9 and connection block 10, the assembly column 2 passes through the After the assembly hole of the frame 3 is assembled, the assembly block 9 and the connecting block 10 are snapped into the assembly groove 12 at the other end of the assembly column 2 to realize fixing, which makes the assembly of the present invention quicker and more convenient, and the outer wall of one end of the assembly column 2 An assembly groove 12 is provided, and the tw...

Embodiment 2

[0034] see Figure 1 to Figure 5 , the present invention provides a technical solution: a steel structure box girder for easy installation, including a box girder main body 1, an assembly frame 3 is sleeved on the end of the box girder main body 1, and the end face of the adjacent assembly frame 3 Fitting each other, the end surface of the assembly frame 3 is provided with an assembly hole, and the assembly column 2 runs through the inside of the assembly hole. Through the designed assembly column 2, assembly groove 12, assembly block 9 and connection block 10, the assembly column 2 passes through the After the assembly hole of the frame 3 is assembled, the assembly block 9 and the connecting block 10 are snapped into the assembly groove 12 at the other end of the assembly column 2 to realize fixing, which makes the assembly of the present invention quicker and more convenient, and the outer wall of one end of the assembly column 2 An assembly groove 12 is provided, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com