A device for detecting yarn quality and controlling waste yarn diversion in the production process

A technology for yarn quality and production process, which is applied in the field of yarn quality detection and control of waste thread diversion equipment, to ensure the diversion effect, help popularize use, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

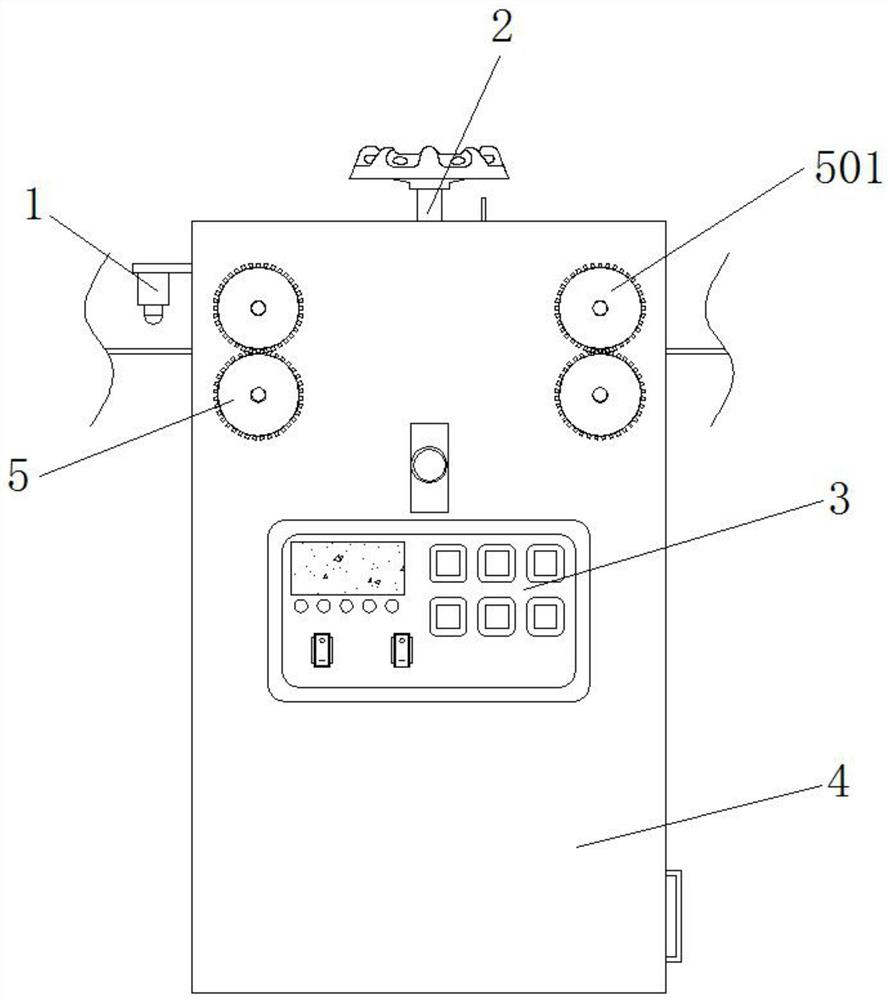

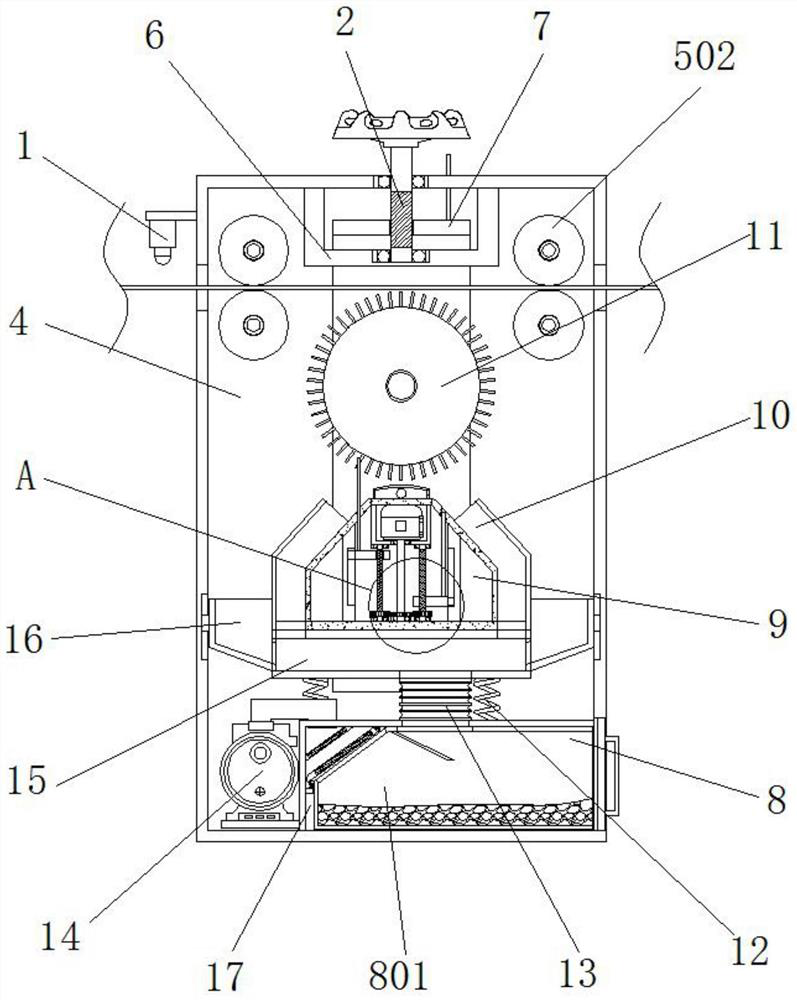

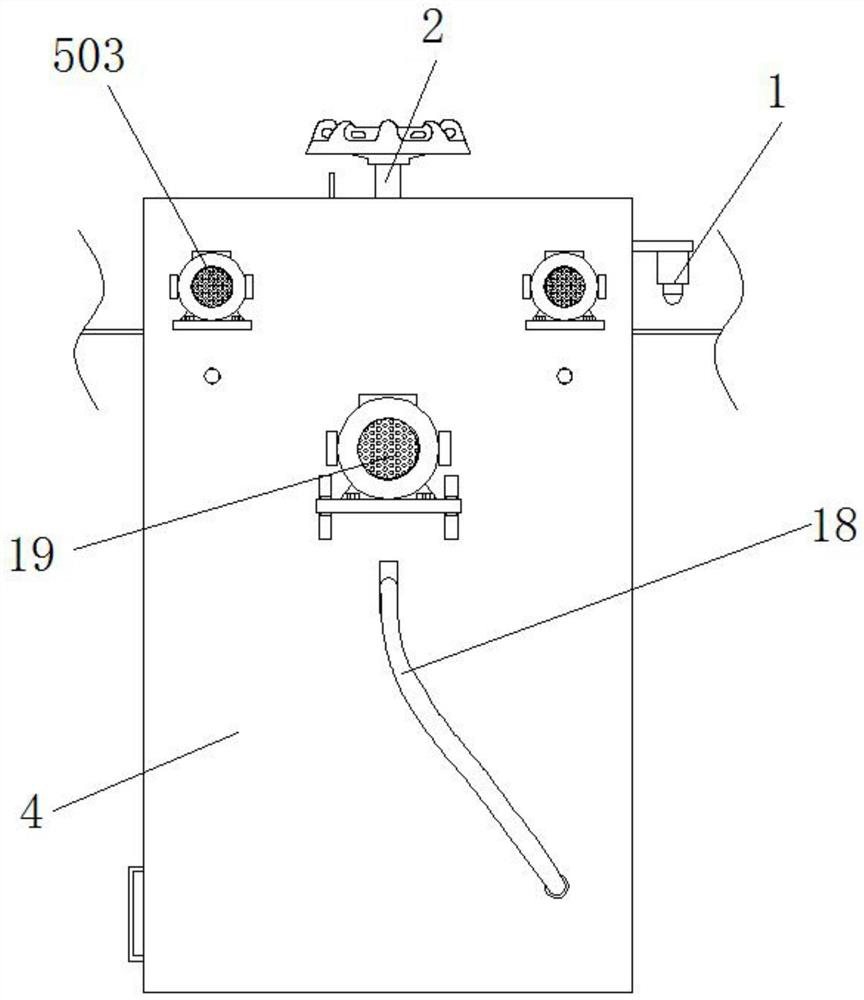

[0039] Example 1, such as Figure 1-7 As shown, when the yarn moves between the two pairs of guide rollers 502, the first threaded rod 2 is manually rotated first, and the U-shaped movable frame 7 is controlled to rise or fall by the thread action, thereby adjusting the distance between the bristles 25 and the yarn , then directly control the driving device 19 to drive the rotating cylinder 11 to rotate, use the rotating bristles 25 to brush off the waste thread on the yarn, and at the same time control the work of the air pump 14, so that the air in the main body compartment 4 passes through the first recovery compartment respectively 10 and the second recovery bin 16 enter the inside of the collection bin 15, and then enter the inside of the collection bin 801 through the telescopic tube 13, and part of the waste lines flying inside the main body bin 4 will be sucked in by the second recovery bin 16, thereby completing the collection. Yarn shunt treatment to avoid waste thre...

Embodiment 2

[0040] Example 2, such as Figure 1-8 As shown, when some waste threads are hung between the bristles 25, the second servo motor 901 can be controlled by the control panel 3 to drive the rotating rod 905 to rotate, and the transmission of the driven gear 904 and the driving gear 908 can be used to drive two groups of second threads. Rod 906 rotates, and due to thread effect, one group of lifting plates 903 rises, and another group of lifting plates 903 descends, and the movable rod 907 on the rising lifting plate 903 can move between multiple groups of bristles 25, and the bristles between bristles 25 The waste thread is scraped to clean the waste thread on the bristles 25, and when the movable rod 907 with the waste thread is retracted into the interior of the installation chamber 902, the waste thread will not enter the interior of the installation chamber 902, but fall off On both sides of the top of the installation bin 902, the waste thread that loses attachments is quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com