Beef jerky production process

A production process and technology of beef jerky, which is applied in the direction of meat/fish preservation, food preservation, food science, etc. It can solve the problems of easily affecting food safety, poor taste, and bitter taste of beef jerky, so as to ensure the quality of smoking, Improve the taste and avoid the effect of large taste deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

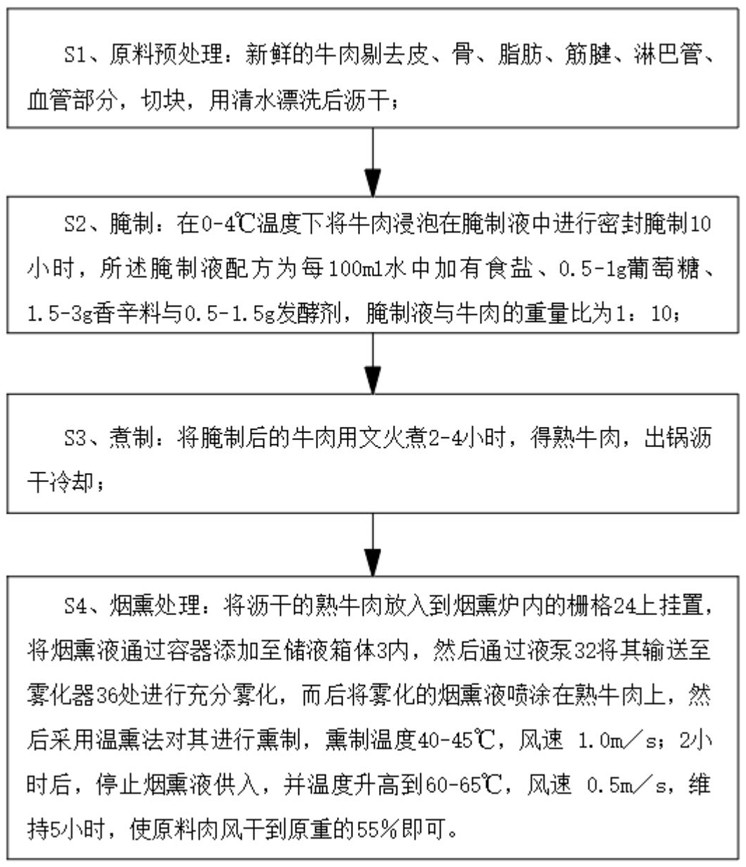

[0039] like Figure 1-Figure 5 Shown, a kind of beef jerky production process comprises the following steps:

[0040] S1. Raw material pretreatment: remove the skin, bones, fat, tendons, lymphatic vessels, and blood vessels from fresh beef, cut into pieces, rinse with water and drain;

[0041] S2. Pickling: Soak the beef in the pickling solution for 10 hours at a temperature of 0-4°C. The formula of the pickling solution is to add salt, 0.5-1g glucose, and 1.5-3g spices per 100ml of water With 0.5-1.5g starter, the weight ratio of marinade to beef is 1:10;

[0042] S3. Cooking: cook the marinated beef with a slow fire for 2-4 hours to get cooked beef, take it out of the pot, drain and cool;

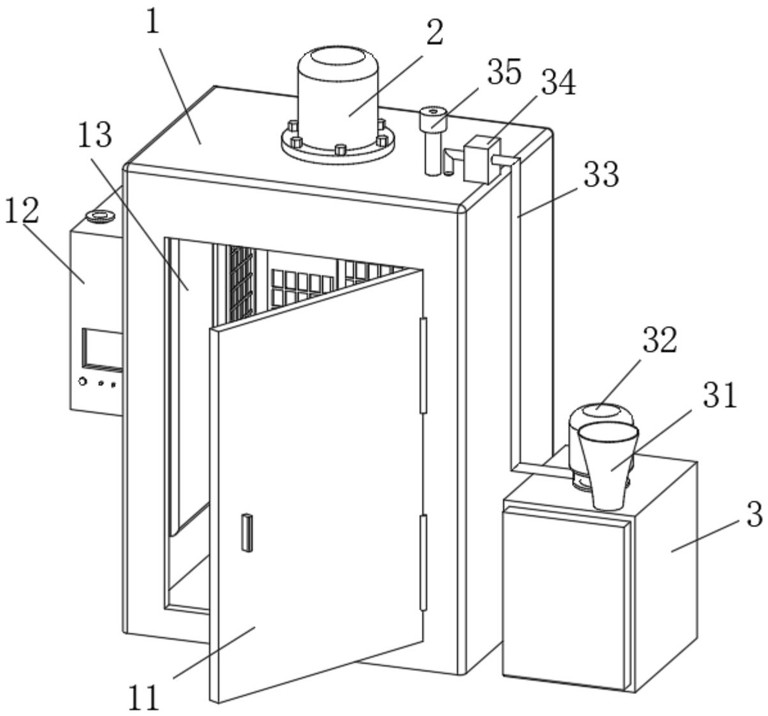

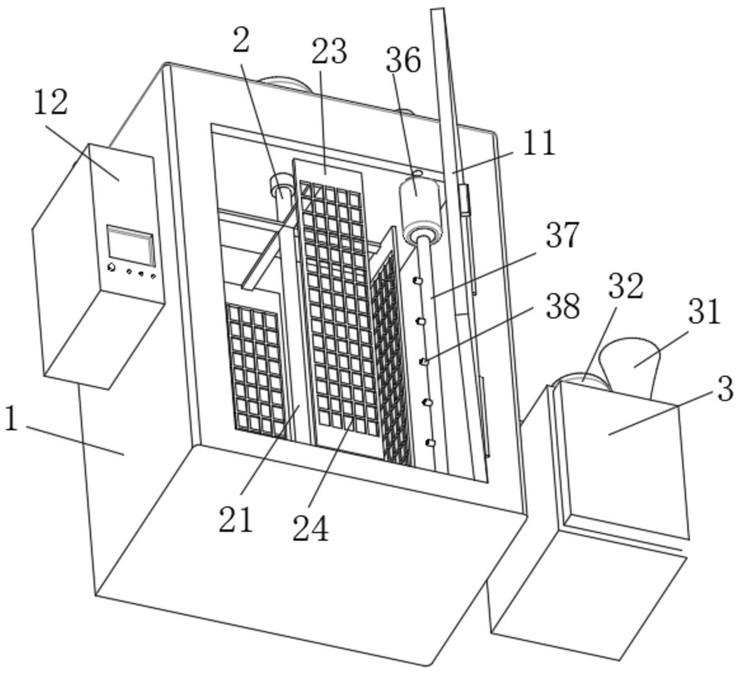

[0043] S4, smoking treatment: put the drained cooked beef on the grid 24 in the smoking furnace and hang it, add the smoked liquid into the liquid storage box 3 through the container, and then transport it through the liquid pump 32 Fully atomize to the atomizer 36, then spray the atom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com