Surface machining method for sealing plug of crossed roller bearing

A cross-roller bearing and surface machining technology, used in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of difficulty, too small sealing block size, and difficult assembly of sealing plugs and mounting holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

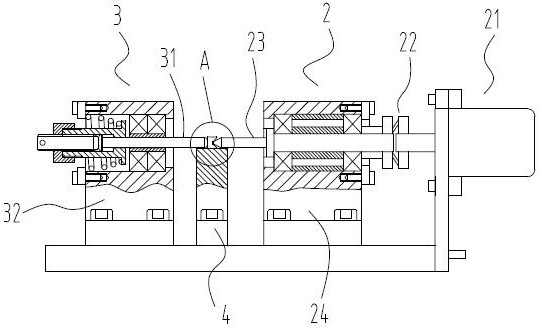

[0039] like image 3 As shown, a finishing machine with a cross roller bearing plug 11 includes a driving assembly 2 , a supporting assembly 4 and a pressing assembly 3 , and the supporting assembly 4 is located between the driving assembly 2 and the pressing assembly 3 .

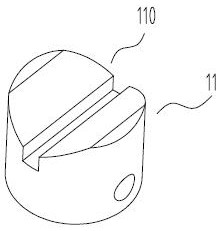

[0040] like image 3 and Figure 4 As shown, the drive assembly 2 includes a power module 21 and a transmission module. The transmission module includes a mounting base 24 and a transmission rod 23. The transmission rod 23 is connected to the mounting base 24 through a bearing. One end of the transmission rod 23 is an adapter end 231 , and the adapter end 231 is provided with a plug 232 , and the plug 232 is inserted into the “V”-shaped notch 110 of the sealing plug 11 .

[0041] like image 3 and Figure 4 As shown, the power module 21 drives the transmission rod 23 to rotate, the power module 21 includes a motor, and the motor is connected to the transmission rod 23 through a coupling 22 .

[0042] l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com