An anti-clogging and low-resistance check valve

A low-resistance, anti-blocking technology, used in lift valves, control valves, valve devices, etc., can solve the problems of easy accumulation of impurities and affect the service life of the valve, and achieve the effect of ensuring normal opening, improving service life and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

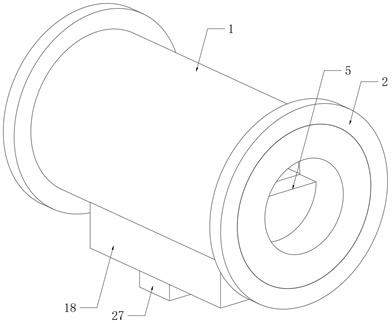

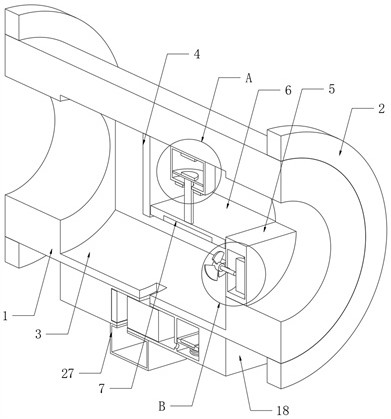

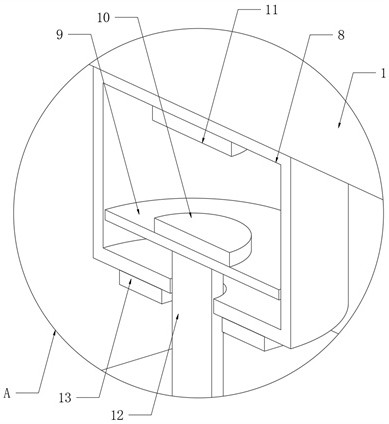

[0020] refer to figure 1 and figure 2 , an anti-clogging and low-resistance check valve, comprising a pipe body 1, flanges 2 are coaxially fixedly connected to the openings at both ends of the pipe body 1, a flow groove 3 is opened in the pipe body 1, and the inner top of the flow groove 3 A baffle 4 is vertically and fixedly connected to the wall, a vertical plate 5 corresponding to the baffle 4 is vertically and fixedly connected to the inner bottom wall of the pipe body 1 near the flow groove 3, and a vertical plate 5 corresponding to the baffle 4 is fixed vertically, and the inner top wall of the flow groove 3 is provided with a The check mechanism matched by the baffle plate 4 and the riser 5, the riser 5 is provided with a power generating mechanism matched with the check mechanism, the lower side of the pipe body 1 peripheral wall is fixedly connected with a fixed block 18, and the fixed block 18 is provided with a stop The slag removal mechanism matched with the retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com