Method for testing working condition of battery of electric bicycle

A technology of electric bicycles and testing methods, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of shortening the test cycle and large gaps, and achieve the effect of shortening the test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

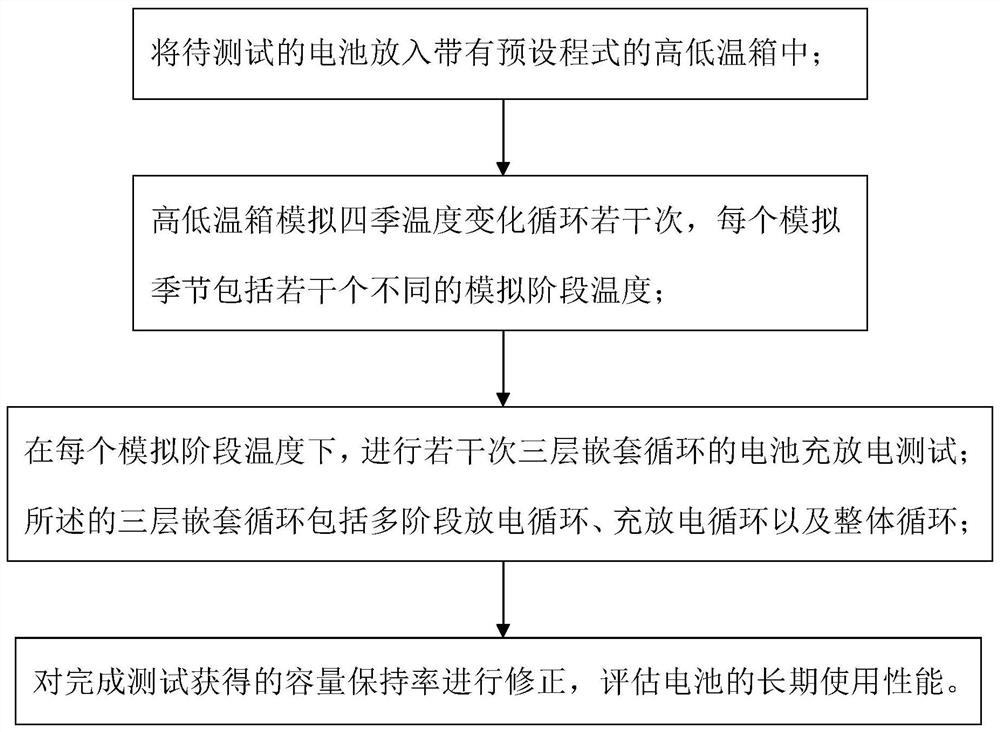

[0049] A working condition test method of an electric bicycle battery in this embodiment, such as figure 1 As shown, including the following steps:

[0050] S1: Put the battery to be tested into a high and low temperature box with a preset program. In the present embodiment, the production of a good 48V12AH battery module is placed in a high and low temperature tank with a program.

[0051] At present, electric bicycle batteries are generally required for three years (capacity retention rate ≥80%) in accordance with the vehicle factory and industry standards, according to civil market research and cycling requirements, the maximum frequency of use (charging time is half an hour above a cycle) About 200 times, three years, 600, in this embodiment, according to this standard, test its performance.

[0052] S2: High and low temperature box simulation sequence temperature variation cycle, each simulation season includes several different simulation stage temperatures.

[0053] Each si...

Embodiment 2

[0094] In the present embodiment, the production of 48V12AH battery modules will be placed in a high and low temperature box set with a program.

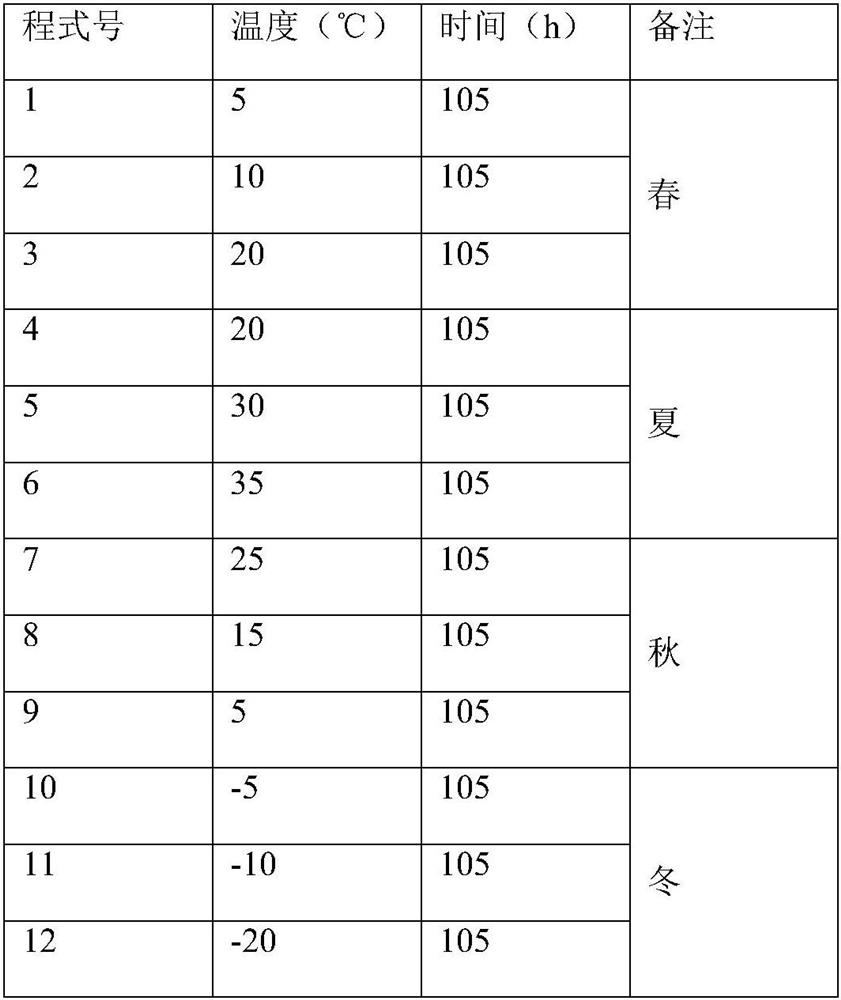

[0095] The high and low temperature box program set according to the four seasons temperature changes, the battery can test 200 cycles, and the programs in the high and low temperature box of the present embodiment are shown in Table 5:

[0096] Table 5. Embodiment of the high and low temperature box

[0097]

[0098] The above temperature setting According to the target use area (South), the average temperature in previous years.

[0099] According to the national standard test requirements, the charger current size, the rated power of the vehicle (current is non-linear), and the general riding habits (charging power is 100% SOC, the discharge power is generally controlled at 10-20% SOC ) To set the test process, the battery charge and discharge test process in this embodiment is shown in Table 6:

[0100] Table 6. Embodiment 2 Batte...

Embodiment 3

[0107] In the present embodiment, the production of a good 48V12AH battery module is placed in a high and low temperature tank with a program.

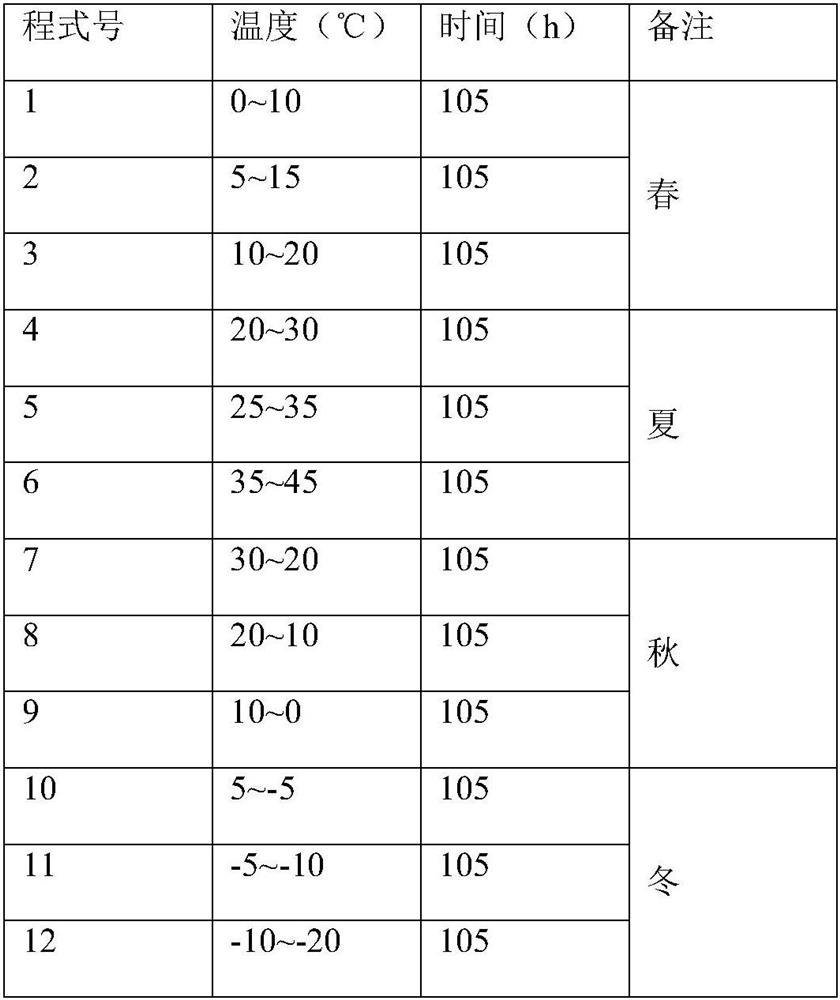

[0108] The program set in the high and low-temperature box is set according to the four seasons of temperature changes. The battery can test 200 cycles in the four seasons. The programs in the high and low temperature tanks in this embodiment are shown in Table 7:

[0109] Table 7. Program in the high and low temperature box in Example 3

[0110]

[0111]

[0112] The above temperature setting is based on the average temperature in the year (Northeast).

[0113] According to the national standard test requirements, the charger current size, the rated power of the vehicle (current is non-linear), and the general riding habits (charging power is 100% SOC, the discharge power is generally controlled at 10-20% SOC ) To set the test flow, the battery charge and discharge test process in this embodiment is shown in Table 8:

[0114] Table 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com