Object defect detection method and device, electronic equipment and storage medium

A defect detection and defect technology, applied in the field of defect identification, can solve the problems of low performance of full-scale defect detection and poor detection effect of extreme-scale defects, and achieve the effect of improving detection performance and detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

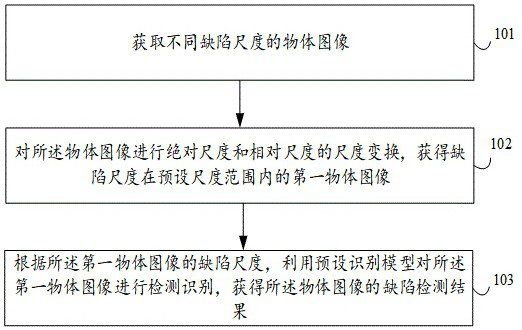

[0052] An embodiment of the present invention provides a method for object defect detection, such as figure 1 As shown, the method includes:

[0053]Step 101: Obtain object images of different defect scales;

[0054] Step 102: Perform scale transformation of the absolute scale and relative scale on the object image to obtain a first object image whose defect scale is within a preset scale range;

[0055] Step 103: According to the defect scale of the first object image, use a preset recognition model to detect and recognize the first object image, and obtain a defect detection result of the object image.

[0056] Specifically, this embodiment can detect defects on the surface of objects such as hot-rolled steel strips.

[0057] In practical applications, the object image can be collected by the camera, and the defect scale of the object image can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com