Low-voltage overhead line live insulation connecting and guiding tool and using method thereof

An overhead line and overhead wire technology, which is applied in the directions of overhead line/cable equipment, insulated/armored cable repair equipment, electrical components, etc. order and other issues, to achieve the effect of simple structure, strong practicability, and improved possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

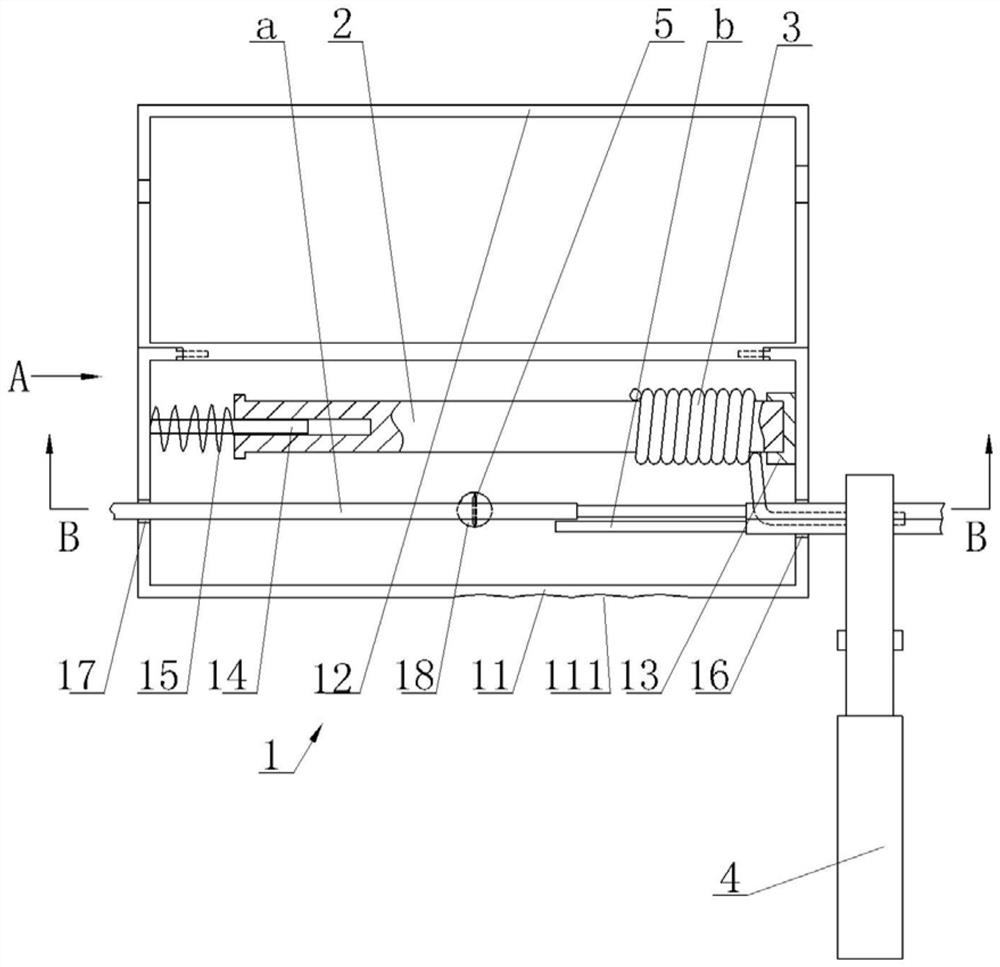

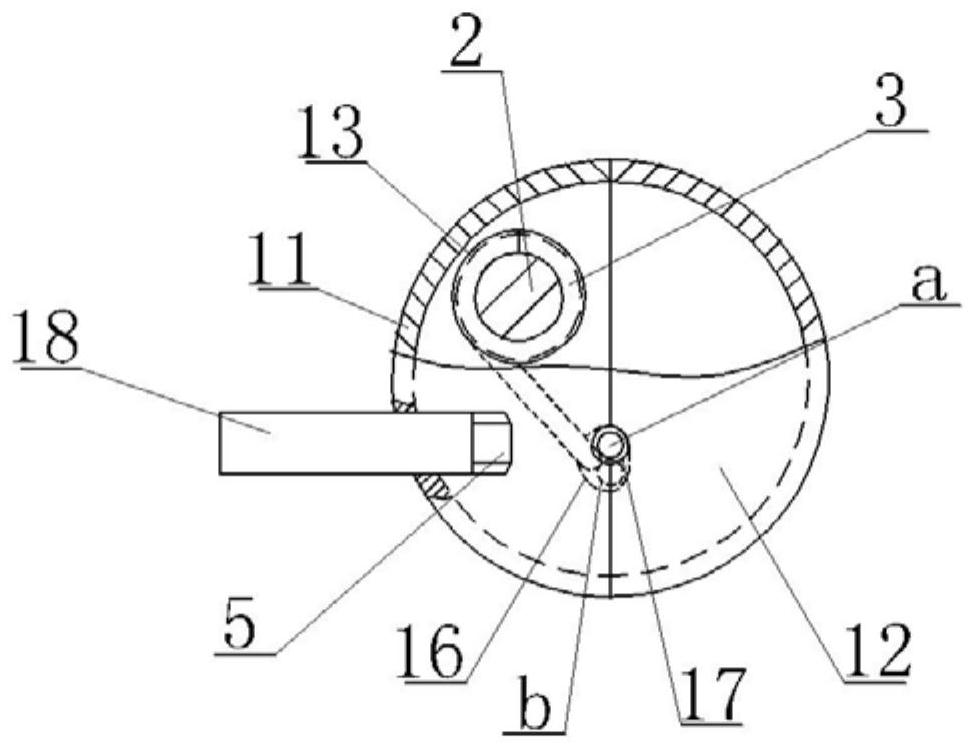

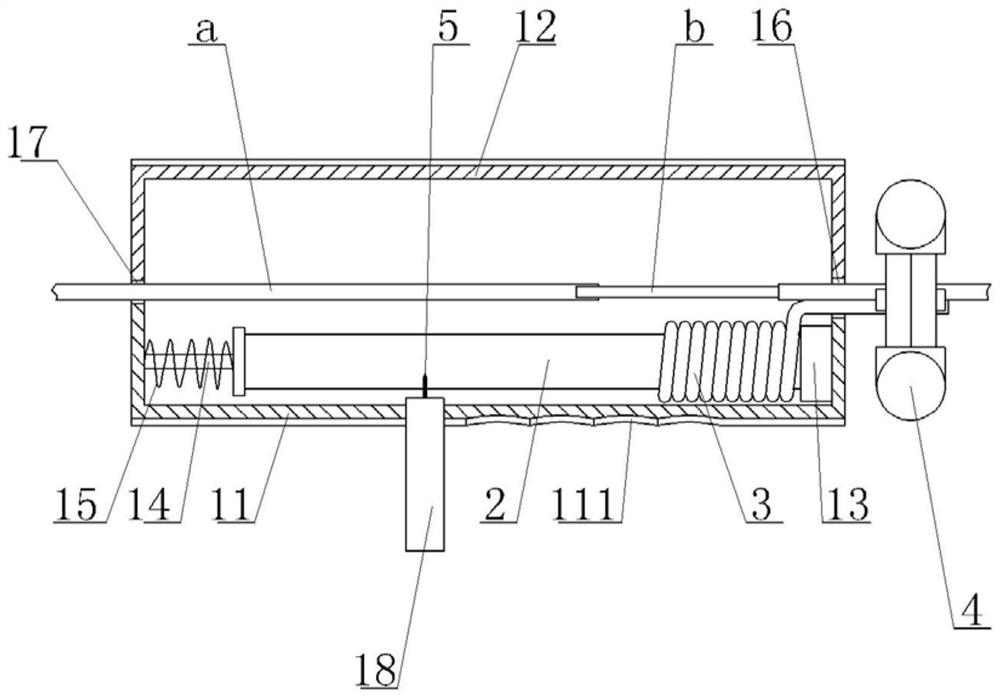

[0044] from Figure 1 to Figure 3 It can be seen that this low-voltage overhead line live insulating connection tool of the present invention is used to connect the overhead wire a to be T-connected and the T-connected wire b, including an insulating clamshell box 1, a winding rod 2, a binding wire 3 and an insulating carp pliers 4,

[0045] The insulating clamshell box 1 includes an insulating box body 11 and an insulating transparent box cover 12 hinged on the insulating box body 11, and one end of the insulating box body 11 and the insulating transparent box cover 12 is divided up and down for clamping overhead wires a and T. The first card slot 16 of the wire b and the binding wire 3 is divided up and down at the other end of the insulating box body 11 and the insulating transparent box cover 12. There is a second card slot 17 for clamping the overhead wire a, and the axis of the second card slot 17 is Arranged through the first card slot 16, a positioning sleeve 13 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com