Stirring machine capable of calibrating non-uniform areas

A mixer and area technology, applied in the field of mixers that can calibrate uneven areas, can solve problems such as manual difficulty in finding, waste, and affecting the quality of final products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

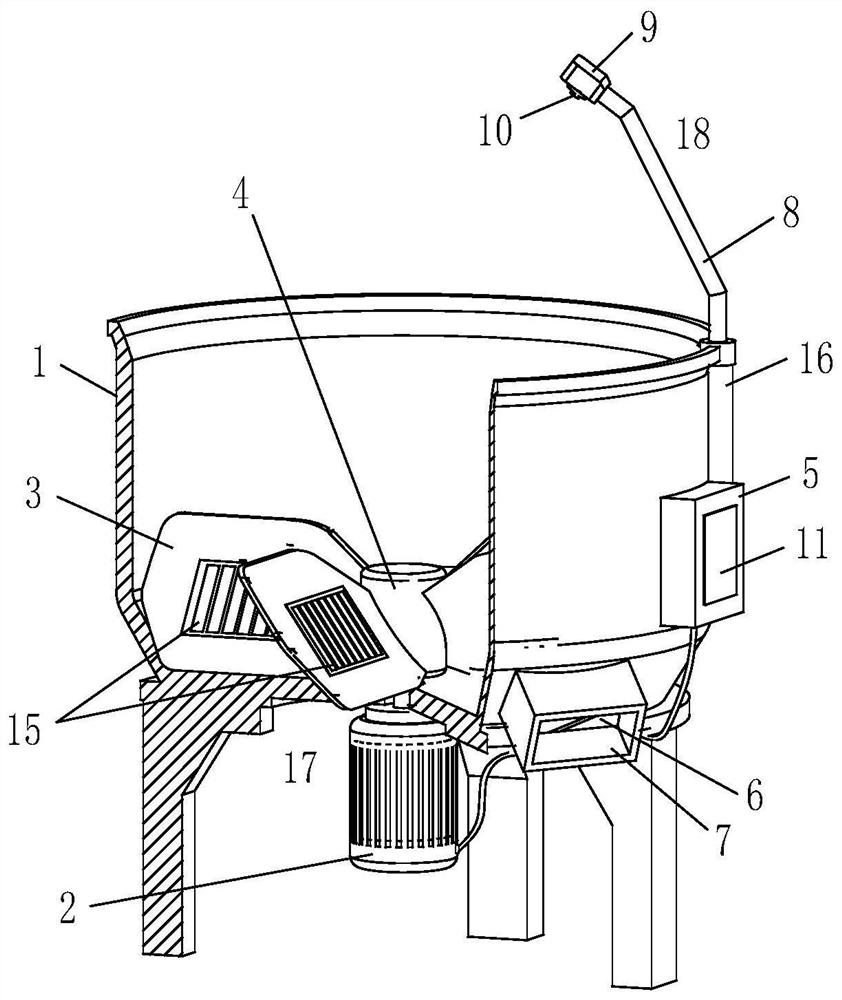

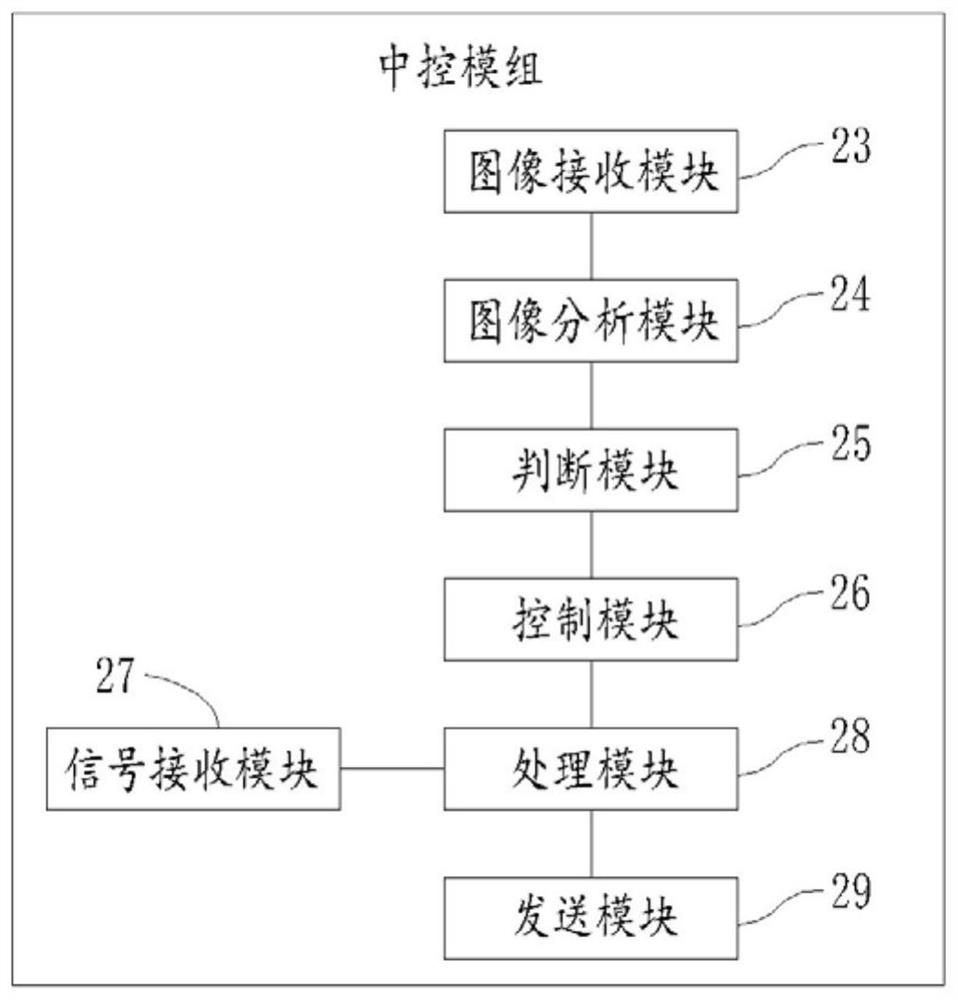

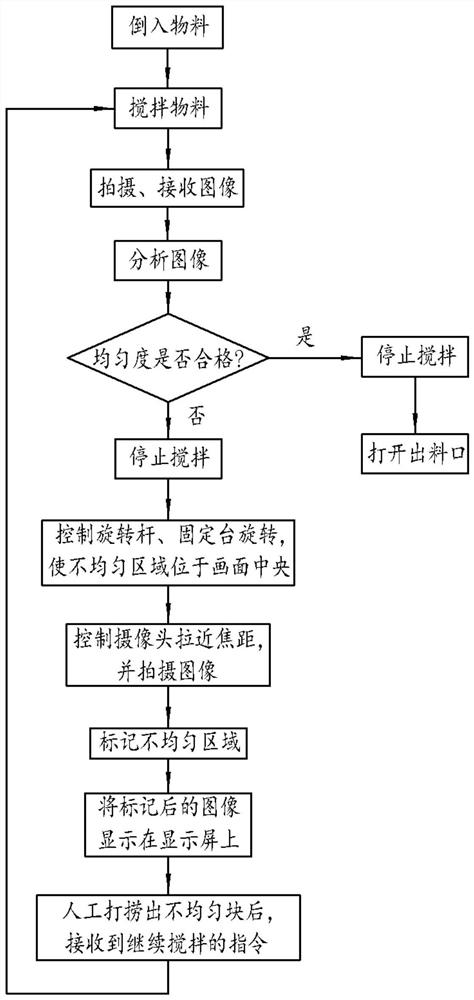

[0030] see figure 1 , in an embodiment of the present invention, a mixer, its structure includes: mixer housing 1, stirring motor 2, stirring blade 3, stirring shaft 4, central control module 5, discharge switch 6, discharge port 7, camera bracket 8. Camera fixing table 9 , camera 10 , display screen 11 , strain gauge group 15 , rotating shaft 16 , and image acquisition component 18 .

[0031] The stirring motor 2 is fixed on the mixer shell 1, and the stirring shaft 4 is connected to the shaft of the stirring motor 2; the stirring blade 3 is fixed on the stirring shaft 4, and the stirring blade 3 has a certain inclination angle, so as to stir the lower layer materials to the upper layer, and the materials The purpose of thorough mixing between.

[0032] A strain gauge group 15 is installed on the stirring blade 3. When the stirring blade 3 touches a foreign object, it will deform briefly and slightly, resulting in a sudden change in the voltage of the strain gauge group 15. ...

Embodiment 2

[0043] The difference from the first embodiment is that after the uneven area in the material is analyzed, the uneven block is clamped out by a manipulator. Specifically:

[0044] Such as Figure 4 and Figure 5 As shown, the manipulator base 12 is installed on the mixer, the end of the manipulator 13 is equipped with a manipulator 14, and the manipulator 14 is connected to the manipulator 13 shafts, and the manipulator includes a gripper 19, a manipulator motor 20, a protective shell 22, and a mounting seat 21 , the manipulator motor 20 drives the jaws 19 to open and close, and the protective shell 22 is installed outside the manipulator motor 20 to protect the motor from bumping and prevent the motor from wading. The mounting base 21 is connected to the mechanical arm 13 by bolts, and the jaws 19 The mesh structure can effectively leak normal particle materials back into the mixer, and only filter out sticky matter and foreign matter, etc. The jaws 19 can be replaced flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com