Barbecue charcoal packaging equipment

A barbecue carbon and equipment technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as low efficiency, increased labor costs, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

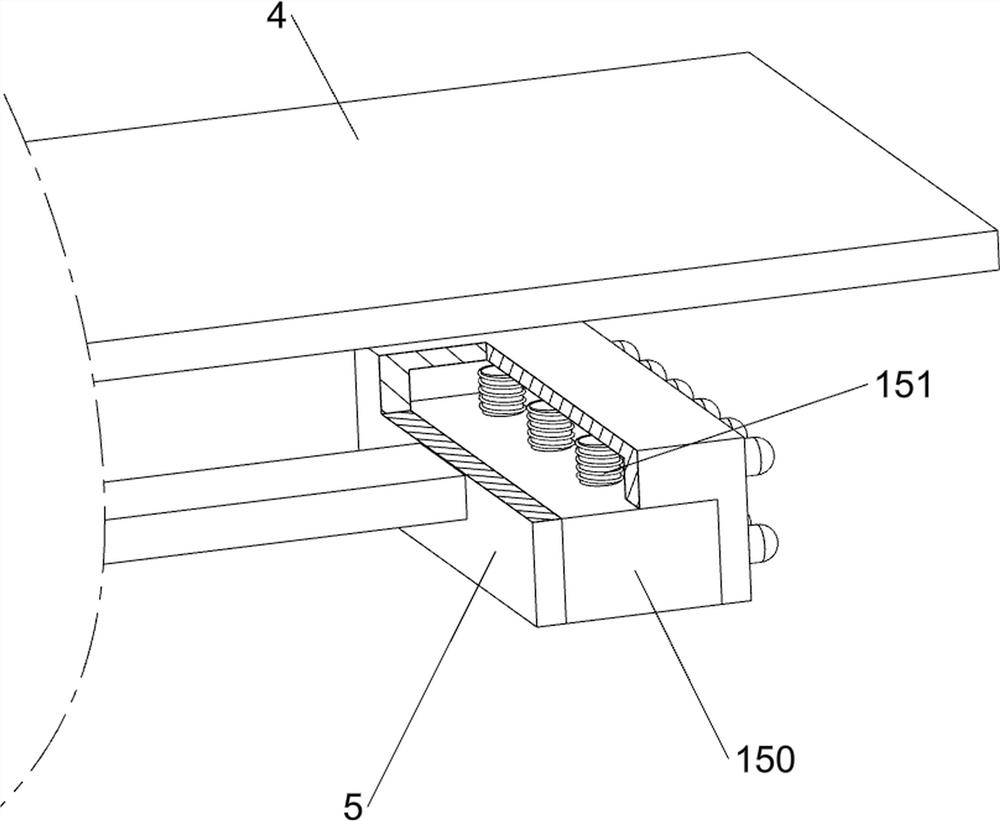

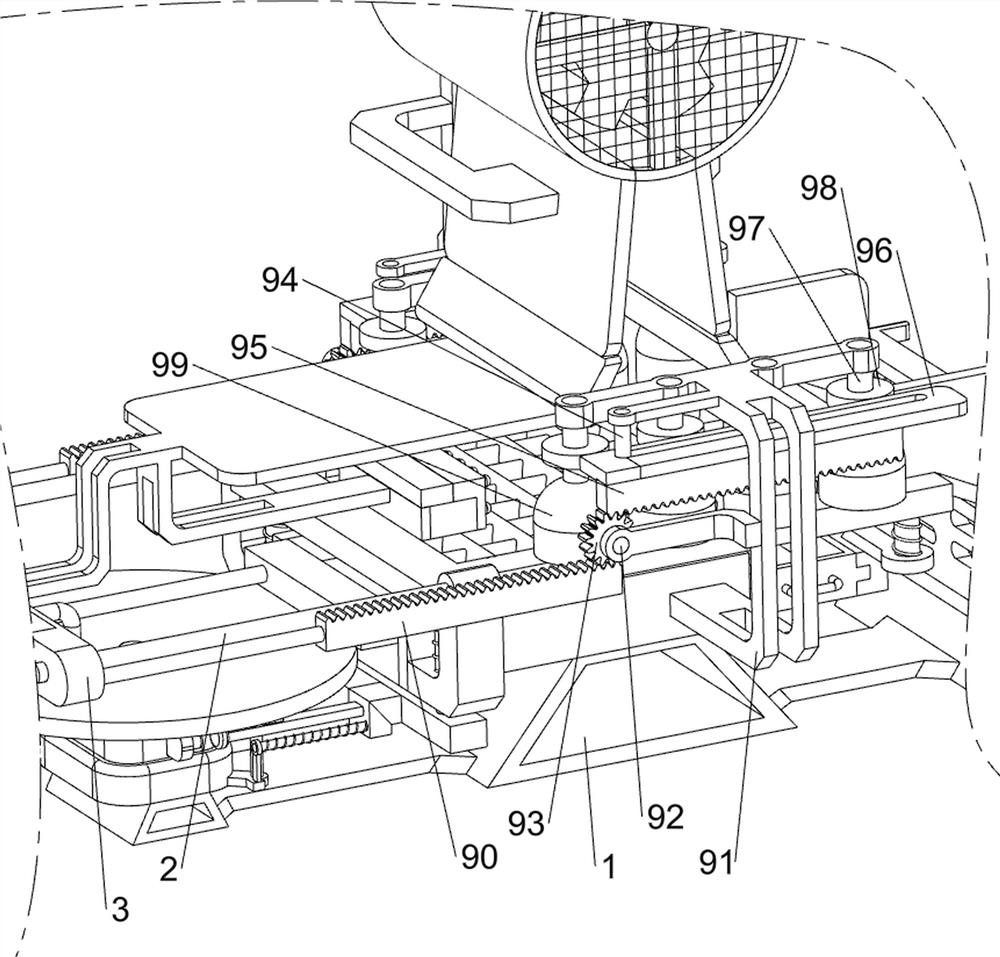

[0032] A packaging device for barbecue carbon, such as Figure 1 to Figure 5 As shown, it includes a base plate 1, a first limit rod 2, a first moving rod 3, a first baffle plate 4, a first push block 5, a first filter screen 6, a first return spring 7, a pushing mechanism 8 and an auxiliary The propulsion mechanism 9, two first limit rods 2 are provided on the left side of the top of the bottom plate 1, the first moving rod 3 is slidably connected between the first limit rods 2, and the first stop is connected to the right side of the first moving rod 3 Plate 4, the first push block 5 is connected to the bottom of the first baffle plate 4, the first filter screen 6 is slidably connected between the front and rear sides of the upper part of the bottom plate 1, and four first return springs 7 are arranged on the top of the bottom plate 1. The return force spring 7 cooperates with the first filter screen 6 , the bottom left side of the bottom plate 1 is provided with a push mech...

Embodiment 2

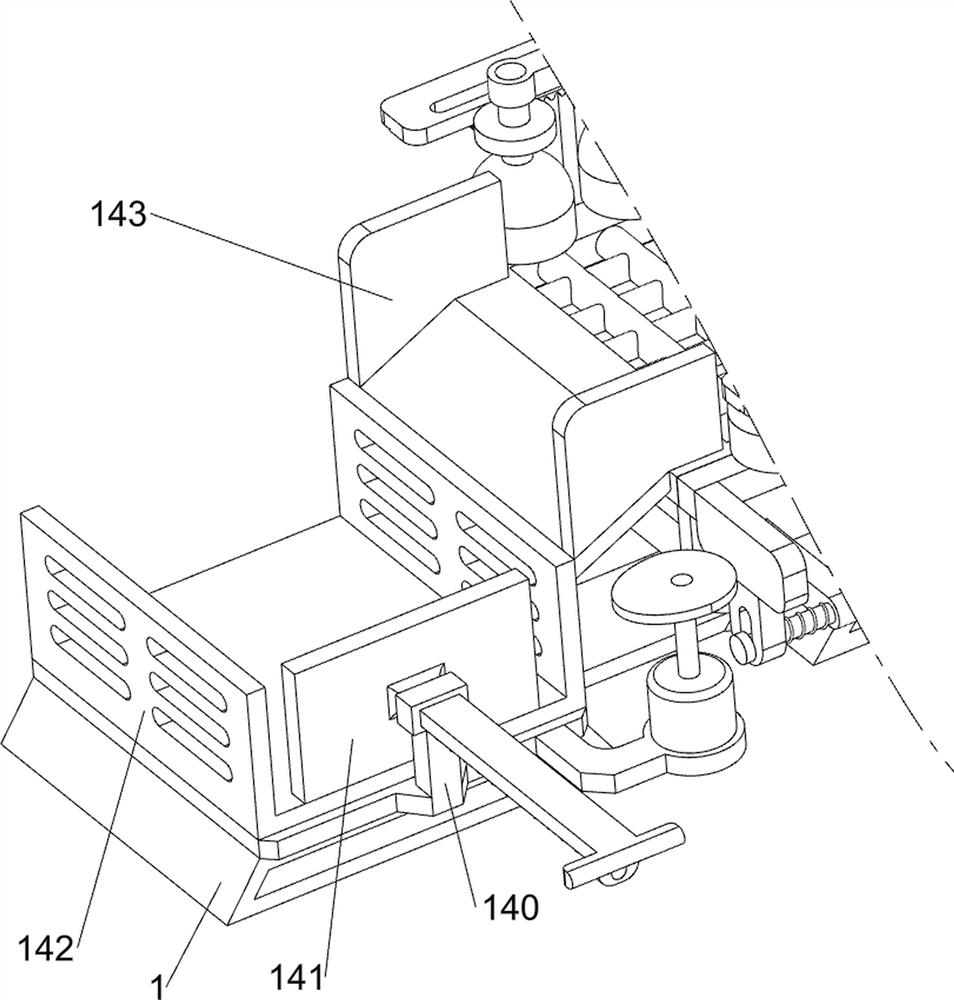

[0037] On the basis of Example 1, such as figure 1 , Image 6 with Figure 7 As shown, it also includes a blanking mechanism 10, the blanking mechanism 10 includes a second support frame 100, a first motor 101, a second rotating shaft 102, a blanking wheel 103, a funnel 104 and a second filter screen 105, the rear side The top of the first support frame 91 is provided with a second support frame 100, the top of the second support frame 100 is provided with a first motor 101, the middle part of the second support frame 100 is connected with a funnel 104, and the front and rear sides of the top of the funnel 104 are provided with a second The filter screen 105 and the upper part of the funnel 104 are rotatably connected with a second rotating shaft 102 , the second rotating shaft 102 is connected with the starting shaft of the first motor 101 , and the second rotating shaft 102 is provided with a feeding wheel 103 .

[0038] It also includes an on-off mechanism 11. The off-off...

Embodiment 3

[0041] On the basis of Example 2, such as Figure 8 to Figure 11 As shown, a cleaning mechanism 12 is also included. The cleaning mechanism 12 includes a second push block 120, a storage box 121 and a handle 122. The right side of the first moving rod 3 is connected with a second push block 120. The second push block 120 is connected to the base plate. 1 The inner wall of the top is slidingly connected, and the right side of the bottom plate 1 is slidingly placed with a storage box 121, and the front side of the storage box 121 is provided with a handle 122.

[0042] Also include shaking mechanism 13, shaking mechanism 13 includes second motor 130, the 5th rotating shaft 131, cam 132 and the 4th return force spring 133, bottom plate 1 rear right side is provided with second motor 130, the starting of second motor 130 The top of the shaft is connected with a fifth rotating shaft 131 , and the top of the fifth rotating shaft 131 is provided with a cam 132 . The cam 132 cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com