High-efficiency environment-friendly metal screen plate etching process method

A technology of metal stencil and process method, which is applied in the field of high-efficiency and environment-friendly metal stencil etching technology, which can solve the problems of non-environmental protection and high efficiency of stencil etching, and achieve the effects of improving surface finish, low pollution, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

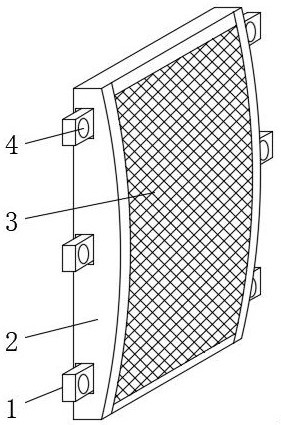

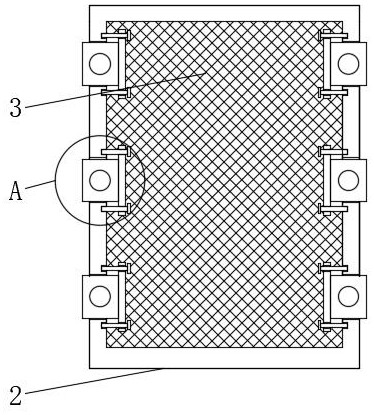

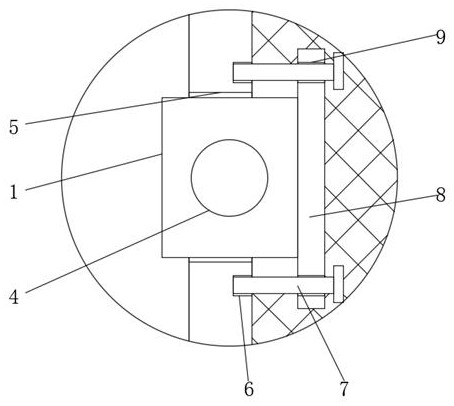

[0035] Such as Figure 1-3 As shown, the embodiment of the present invention provides an efficient and environment-friendly metal mesh panel, including an installation frame 2 and a metal mesh panel 3, the metal mesh panel 3 is arranged in the middle of the installation frame 2, and both sides of the installation frame 2 are provided with telescopic holes 5 There are three telescopic holes 5 arranged at equal intervals. A positioning block 1 is arranged inside the telescopic hole 5. The middle part of the positioning block 1 is provided with a mounting hole 4. The rear end of the positioning block 1 is fixedly connected to the inside of the mounting frame 2. There is a positioning plate 8 to facilitate the expansion and contraction of the positioning block 1 to the inside of the installation frame 2, so that it is easy to carry and install, and can be installed and used effectively.

[0036] The upper and lower ends of the limiting plate 8 are provided with a second connecting...

Embodiment 2

[0038] The high-efficiency and environment-friendly metal mesh etching process method comprises the following etching process steps:

[0039] S1. Selection of metal plate materials, the selected metal plate is cut, cut into the required size, cleaned and dried, and the metal plate is subjected to electrostatic dust removal so that the dust will not be adsorbed on the surface of the metal plate;

[0040] S2. Degreasing the metal plate, using soaking to degrease, placing the metal plate in a box filled with water-based degreasing agent for soaking and degreasing treatment, and using auxiliary equipment to improve the degreasing process. oil efficiency;

[0041] S3. After the degreasing is completed, the metal plate is cleaned with pure water. After cleaning, the metal plate is placed in a dryer for drying to keep the metal plate dry;

[0042] S4, apply photosensitive oil, apply photosensitive oil on the surface of the metal plate, after the application, check the metal plate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com