Pipeline corrosion prevention auxiliary framework for judging anode corrosion condition and enhancing protection effect

A technology of protection effect and anodic corrosion, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of reducing the volume of active metal, indeterminate degree of corrosion of active metal, not energy saving and environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

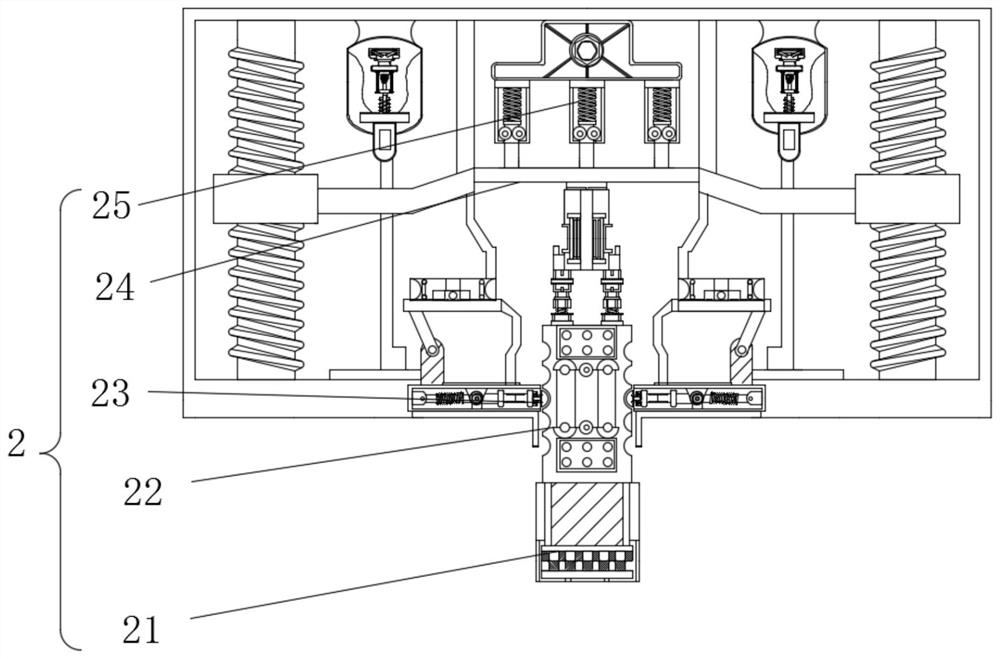

[0025] see figure 1 and figure 2 , a pipeline anti-corrosion auxiliary structure for judging the anode corrosion status and enhancing the protection effect, including a pipeline structure 1, a gravity mechanism 2 is movably connected to the interior of the pipeline structure 1, and a transmission mechanism 3 is movably connected to the left and right sides of the gravity mechanism 2, and the transmission mechanism 3 A one-way mechanism 4 is movably connected to the side away from the gravity mechanism 2, the top of the one-way mechanism 4 is movably connected to an adjustment mechanism 5, and the bottom of the transmission mechanism 3 is movably connected to a synergistic mechanism 6.

[0026] Further, the gravity mechanism 2 includes an active metal 21, a progressive plate 22, a card delivery block 23, a horizontal plate 24 and a tension spring 25. The top of the active metal 21 is fixedly connected with a progressive plate 22, and the left and right sides of the progressive...

Embodiment 2

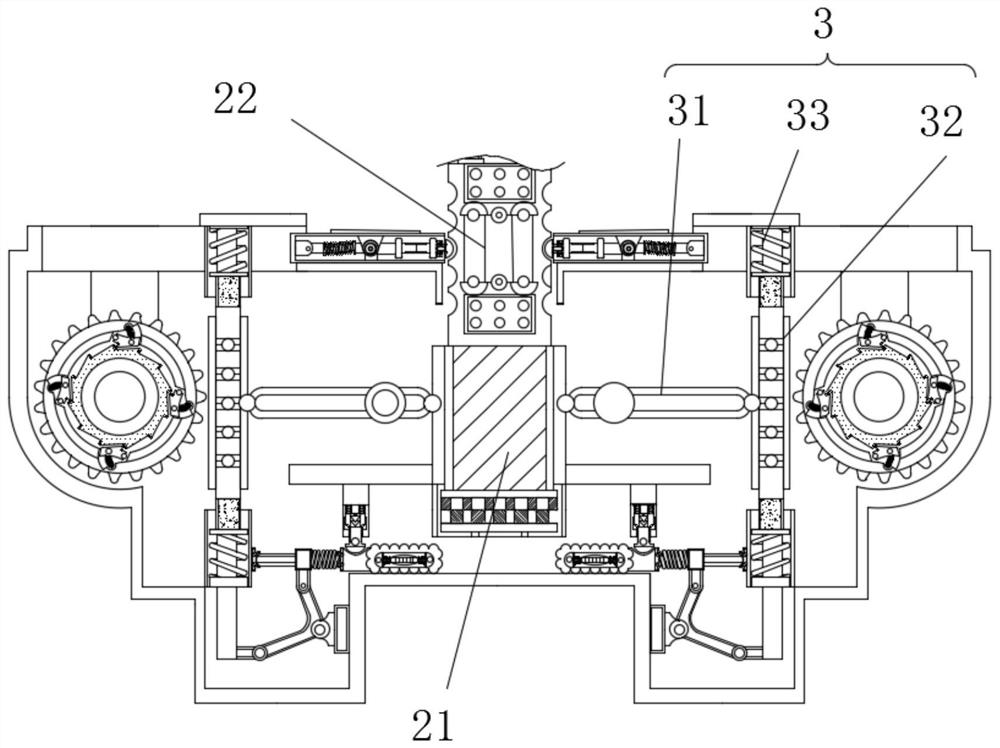

[0029] see figure 1 , image 3 and Figure 4 , a pipeline anti-corrosion auxiliary structure for judging the anode corrosion status and enhancing the protection effect, including a pipeline structure 1, a gravity mechanism 2 is movably connected to the interior of the pipeline structure 1, and a transmission mechanism 3 is movably connected to the left and right sides of the gravity mechanism 2, and the transmission mechanism 3 A one-way mechanism 4 is movably connected to the side away from the gravity mechanism 2, the top of the one-way mechanism 4 is movably connected to an adjustment mechanism 5, and the bottom of the transmission mechanism 3 is movably connected to a synergistic mechanism 6.

[0030] Further, the transmission mechanism 3 includes a lever 31 , a rack plate 32 and a spring rod 33 , the surface of the lever 31 is movably connected to the rack plate 32 , and the upper and lower sides of the rack plate 32 are movably connected to the spring rod 33 .

[0031]...

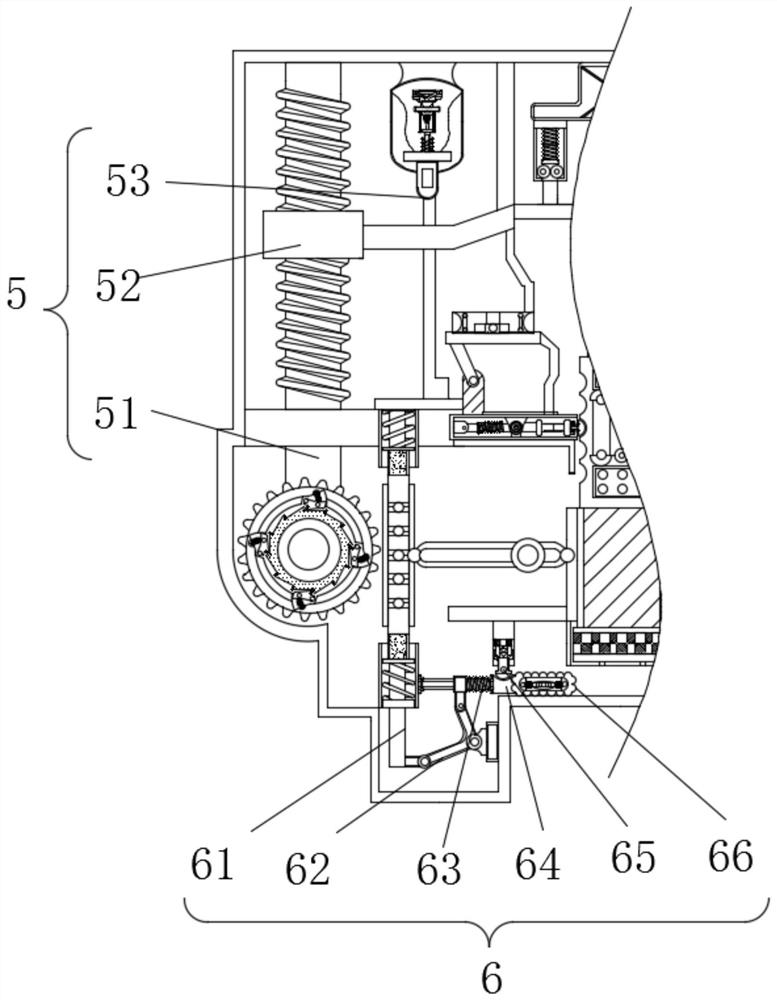

Embodiment 3

[0034] see Figure 1-Figure 4, a pipeline anti-corrosion auxiliary structure for judging the anode corrosion status and enhancing the protection effect, including a pipeline structure 1, and the internal activity connection of the pipeline structure 1 is connected with a gravity mechanism 2, and the gravity mechanism 2 includes an active metal 21, a progressive plate 22, and a card delivery block 23 , horizontal plate 24 and extension spring 25, the top of the active metal 21 is fixedly connected with a progressive plate 22, the left and right sides of the progressive plate 22 are movably connected with a card delivery block 23, and the top of the progressive plate 22 is fixedly connected with a horizontal plate 24. The top of the horizontal plate 24 is movably connected with a tension spring 25, and the clamp block 23 is movably installed inside the pipeline structure 1. The left and right sides of the active metal 21 are movably connected with a lever 31, and the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com