Multifunctional optical experiment test platform

A test platform, multi-functional technology, applied in optical instrument testing, machine/structural component testing, measuring devices, etc., can solve the comprehensiveness and accuracy of the position and angle that affect the shooting, and the comprehensiveness and accuracy of the position and angle that affect the irradiation. and accuracy, the irradiation position and angle are not comprehensive and accurate, etc., to achieve the effect of ensuring experimental test efficiency, beautiful appearance, firm and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

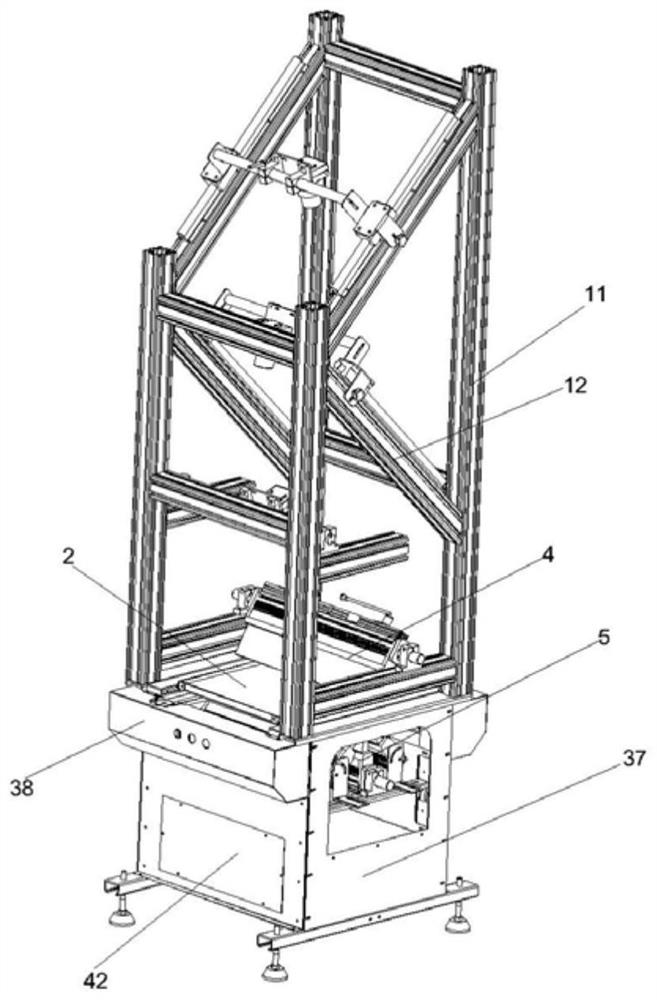

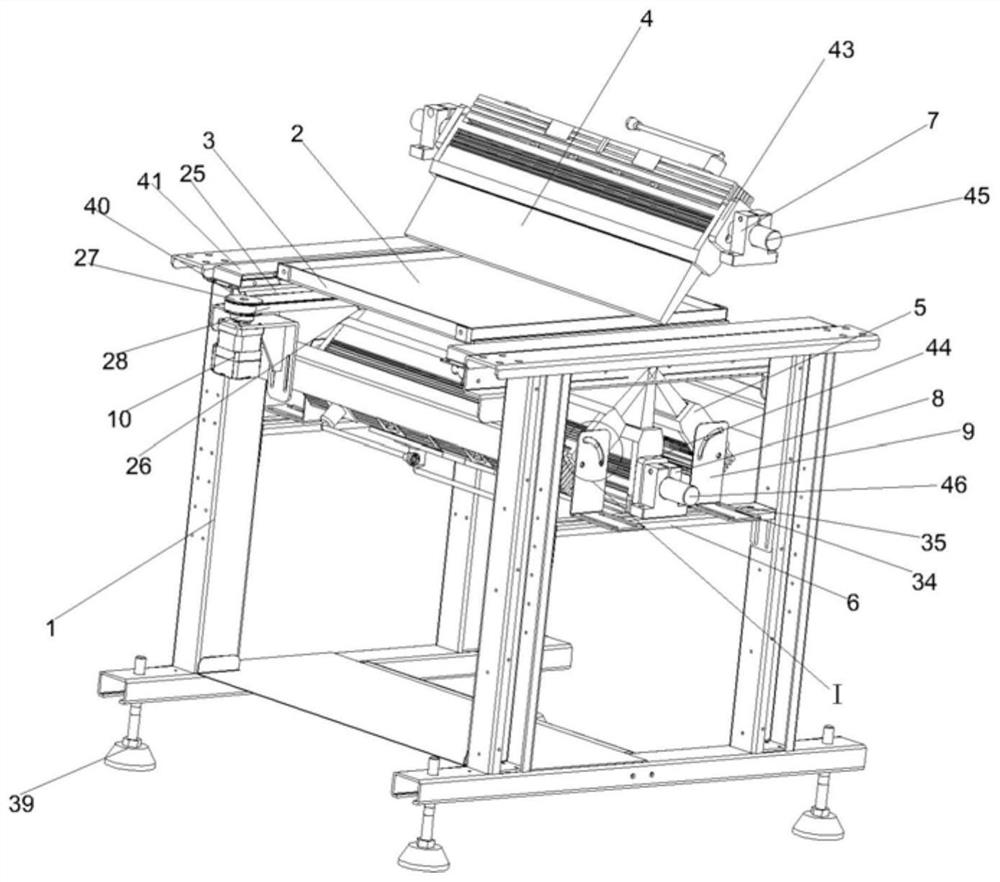

[0038] Such as Figure 1-6 Shown, a kind of multi-functional optical experiment test platform, comprises test support 1, the test glass 2 that is installed on the test support 1, light source assembly and camera assembly, test glass 2 is connected on the test support 1 by a sliding table 3 sliding,

[0039] The light source assembly includes an upper light source 4 located above the test glass 2, three lower light sources 5 located below the test glass 2, and a light source seat plate 6 matching the lower light source 5;

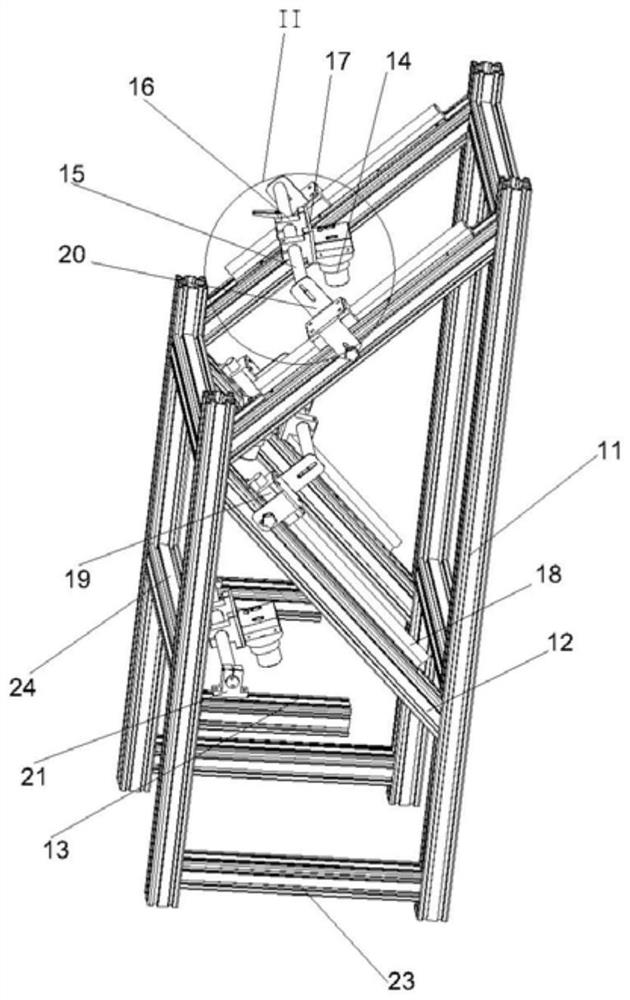

[0040] The camera assembly includes a camera mounting frame, three cameras 14 installed on the camera mounting frame and a camera adjustment mechanism for adjusting the position and angle of the camera 14. The camera mounting frame includes four supporting column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com