Lathe tool wear degree detection device convenient to mark

A lathe tool and detection device technology, applied in the direction of mechanical roughness/irregularity measurement, manufacturing tools, workshop equipment, etc., can solve the problem of no tool wear degree detection equipment, and achieve the effect of easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

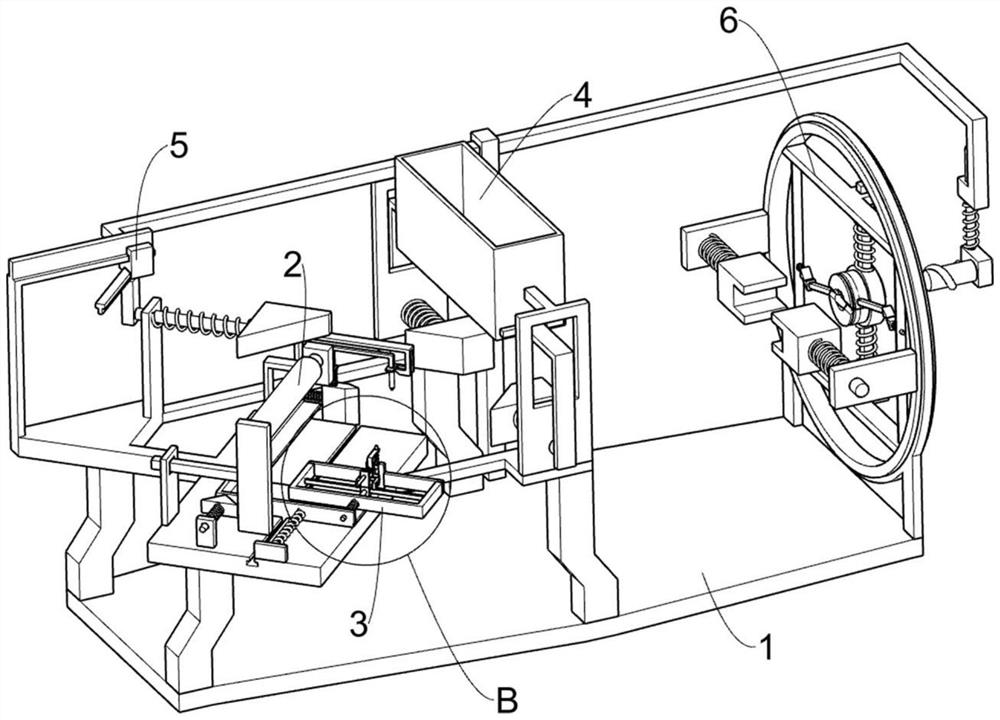

[0026] A lathe tool wear detection device that is convenient for marking, such as Figure 1-5 As shown, it includes a first fixed frame 1, a flatness test mechanism 2 and a wear degree test mechanism 3, and the first fixed frame 1 is provided with a flatness test mechanism 2, which is used to detect the flatness of the cutter head. The testing mechanism 2 is provided with a wear degree testing mechanism 3, and the wear degree testing mechanism 3 is used for detecting the wear degree of the cutter head.

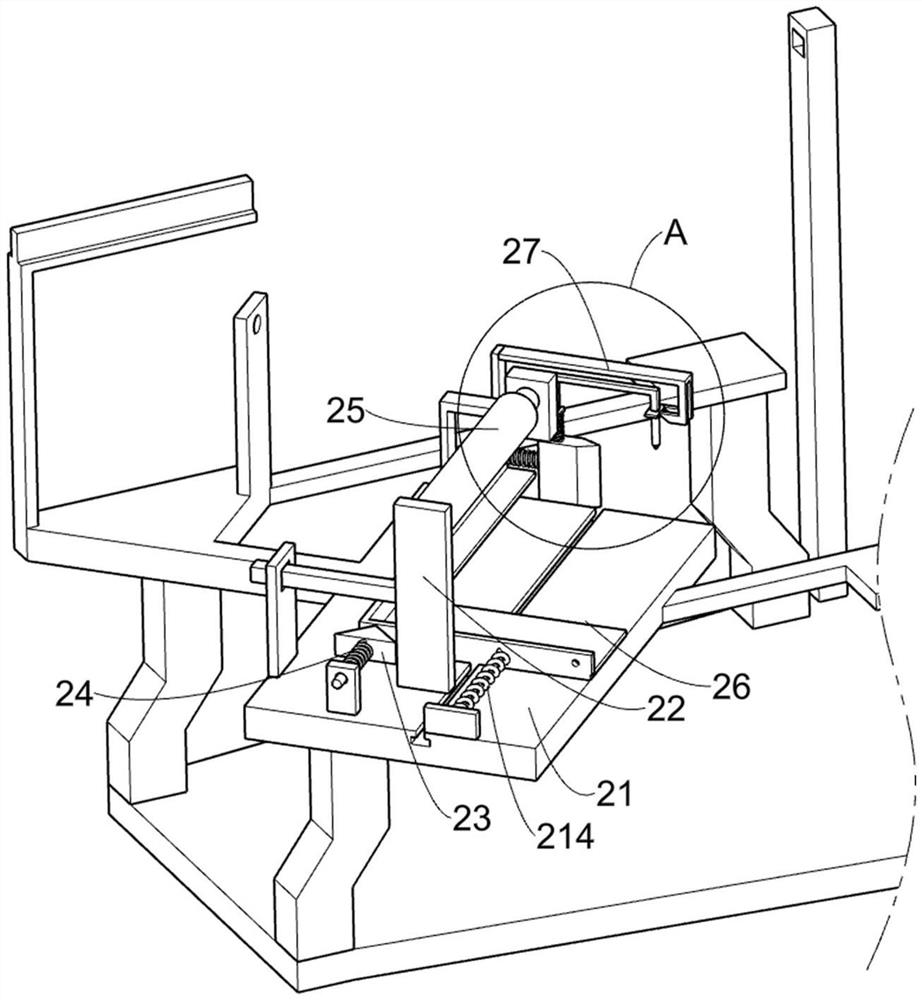

[0027]The flatness testing mechanism 2 includes a second fixed frame 21, a first sliding frame 22, a first wedge block 23, a first return spring 24, an electric push rod 25, a second sliding frame 26, a wedge frame 27, a wedge plate 28, The second return spring 29, the third sliding frame 211, the third return spring 212, the first marking pen 213 and the tension spring 214, the second fixed frame 21 is fixedly installed on the first fixed frame 1, and the first sliding frame ...

Embodiment 2

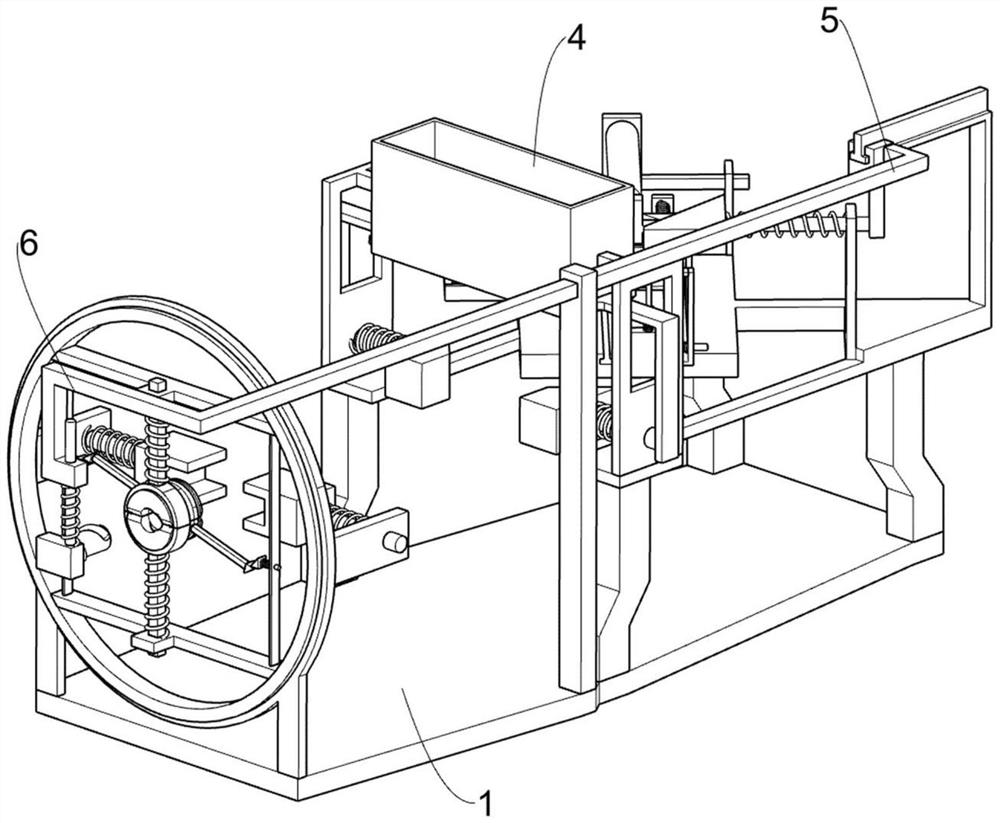

[0033] On the basis of Example 1, such as Image 6 As shown, a cooling mechanism 4 is also included. The cooling mechanism 4 is arranged on the second fixed frame 21. The cooling mechanism 4 is used to cool the cutter head. The cooling mechanism 4 includes a fifth fixed frame 41, a second wedge 42, a second Seven return springs 43, the sixth fixed mount 44 and the fixed frame 45, the fifth fixed mount 41 are symmetrically welded on the second fixed mount 21, the fifth fixed mount 41 is slidably connected with the second wedge block 42, the second wedge block 42 is used for clamping the tool, the second wedge block 42 is fixedly connected with the seventh return spring 43, one end of the seventh return spring 43 away from the second wedge block 42 is connected with the fifth fixed frame 41, and the sixth fixed frame 44 is welded At one end of the second wedge block 42, a fixed frame 45 is jointly supported above the two fifth fixed frames 41, the sixth fixed frame 44 is slidabl...

Embodiment 3

[0036] On the basis of Example 2, such as Figure 6-8 As shown, a reciprocating mechanism 5 is also included, and the reciprocating mechanism 5 is slidably connected on the second fixed frame 21. The reciprocating mechanism 5 includes a third wedge block 51, an eighth return spring 52, a seventh fixed frame 53 and a sixth sliding frame. frame 54, the third wedge block 51 is slidably connected to the second fixed frame 21, the third wedge block 51 is fixedly connected with the eighth return spring 52, one end of the eighth return spring 52 away from the third wedge block 51 and the second The fixed frame 21 is connected, and one end of the third wedge block 51 close to the second fixed frame 21 is welded with a seventh fixed frame 53, and the seventh fixed frame 53 is used to push the sixth sliding frame 54 to move away from the first sliding frame 22. The second fixed frame 21 is slidably connected with a sixth sliding frame 54 , the sixth sliding frame 54 is slidably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com