Broken hair removing equipment for processing disc brush

A disc brush and equipment technology, which is applied in metal processing and other directions, can solve the problems of mixed hairs and poor effect of removing hairs, and achieve the effect of improving stability and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

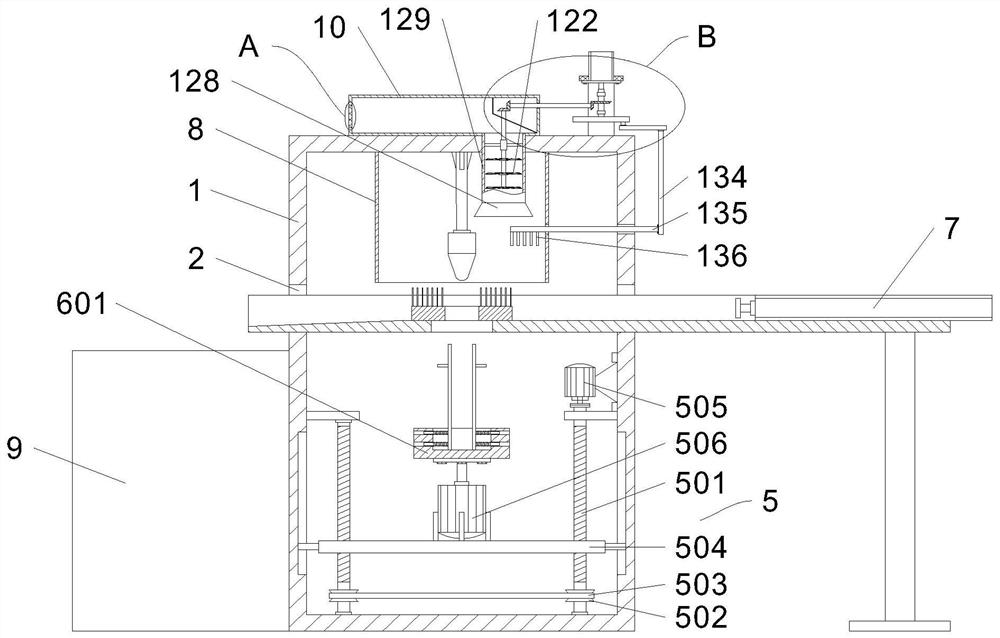

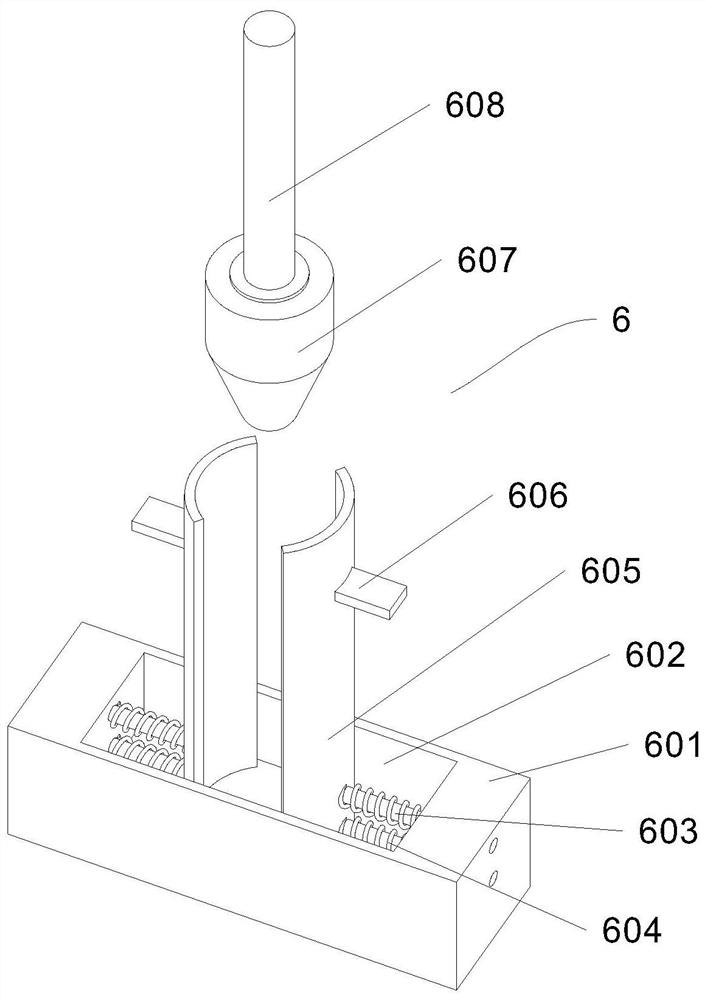

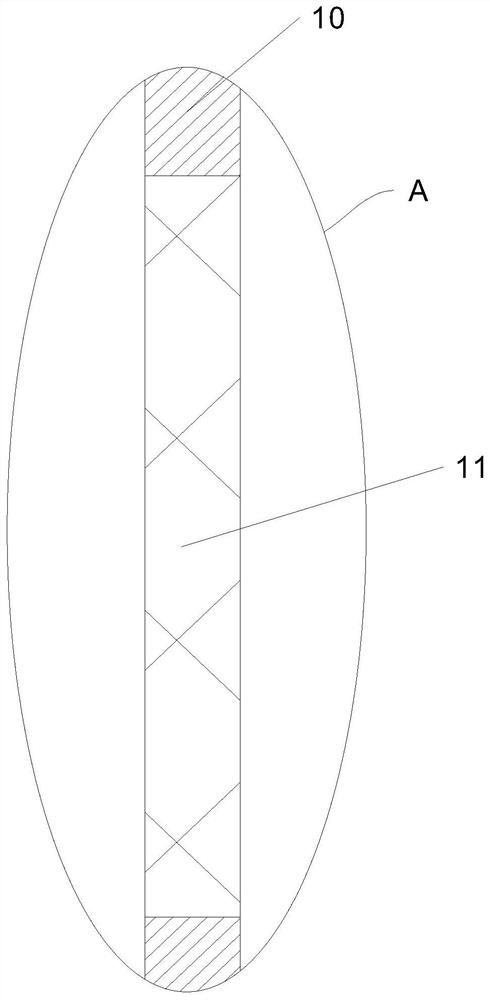

[0030] In this embodiment, as shown in Figures 1-5, a kind of delinting equipment for disc brush processing includes a box body 1 with an incompletely closed front end, a side door is provided at the front end of the box body 1, and a removable Viewing window, the upper part of both side walls of the box body 1 is provided with a port 2, and a loading case 3 for placing a disc brush is fixed between the two openings 2, and the loading case 3 is close to the bottom of the side section of the collection box 9 It is inclined, and the load case 3 is provided with a through groove 4, and the side section of the load case 3 outside the box 1 is fixed with a hydraulic rod 7, and the telescopic end of the hydraulic rod 7 is fixed with a push block. The outer end is located below the end of the loading shell 3 away from the hydraulic rod 7, and a collection box 9 is provided, and a rotary lifting mechanism 5 is provided below the through groove 4 in the box body 1, and a rotary lifting ...

Embodiment 2

[0034] On the basis of Embodiment 1, the inner wall of the temporary storage box 10 is fixed with a protective plate 18 to prevent the broken hairs from entering between the bevel gear one 123 and the bevel gear two 124, so as to avoid the broken hairs from being entangled in the bevel gear one 123 and the bevel gear two 124 and cause damage. The upper parts of the outer ends of the two splints 605 are fixed with a limiting plate 606 to prevent the disc brush from shifting downward, that is, the bottom end of the disc brush abuts against the top of the limiting plate 606 to improve the stability of the disc brush when rotating.

Embodiment 3

[0036] On the basis of embodiment 2, carding mechanism 13 comprises the circular plate 131 that is fixed on the bottom end of rotating shaft three 17, and the bottom end of circular plate 131 is fixed with eccentric rod 132, and the bottom end of eccentric rod 132 is rotatably connected with rotating rod 133, and rotating rod One side of the bottom end of 133 is rotatably connected with a vertical bar 134, and one end of the vertical bar 134 close to the casing 1 is fixed with a cross bar 135 below the suction hood 128, and the bottom end of the cross bar 135 is fixed at a position in the housing 8. A plurality of picks 136 for poking the bristles of the disc brush. Through the above method, the rotating shaft 3 17 rotates, drives the circular plate 131 to rotate, and then drives the eccentric rod 132 to rotate, thereby driving the rotating rod 133 to move, driving the vertical rod 134 connected to the rotating rod 133 to move, thereby driving the horizontal rod 135 to reciproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com