A high-speed textile printing machine for cotton and linen fabrics and its printing process

A printing machine, high-speed technology, applied in the field of textile printing, can solve the problems of expanding the range of dyeing, increasing the depth of dyeing, printing whiteness, etc., to avoid uneven color, improve printing efficiency, and improve adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

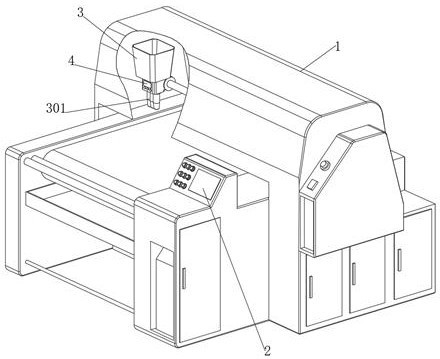

[0054] see Figure 1-10 A high-speed textile printing machine for cotton and linen fabrics, comprising a high-speed printing machine body 1, a textile printing control box 2 fixedly installed on the high-speed printing machine body 1, and a printing dye bucket 3 installed in the high-speed printing machine body 1, The lower end of the printing dye bucket 3 is fixedly connected with an inkjet controller 4 electrically connected to the textile printing control box 2, and the lower end of the printing dye bucket 3 is fixedly connected with a dye inkjet tube 301 connected thereto. The lower end of the tube 301 is fixedly connected with a taper adjustment nozzle 5, and the taper adjustment nozzle 5 is fixedly connected with a plurality of needle point adjustment nozzles 6 connected with the dye ink jet tube 301, and the outer end of the needle point adjustment nozzle 6 is connected with a dyeing nozzle. Dye diffusion and immersion assembly 7, the outer end of the needle point adjus...

Embodiment 2

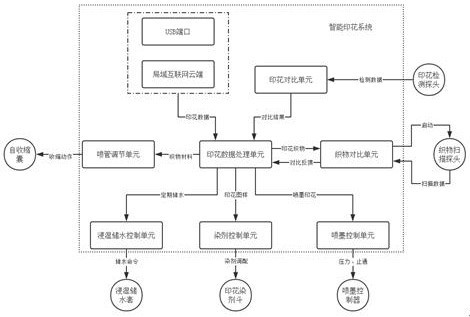

[0058] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to image 3 , the textile printing control box 2 is provided with an intelligent printing system that cooperates with the high-speed printing machine body 1. The intelligent printing system includes a printing data processing unit, and the input ends of the printing data processing unit are respectively connected to a USB port and a local Internet cloud. The output end of the data processing unit is respectively connected with the dye control unit, the inkjet control unit, the soaking water storage control unit and the nozzle adjustment unit, the output end of the dye control unit is electrically connected with the printing dye hopper 3 through a wire, The...

Embodiment 3

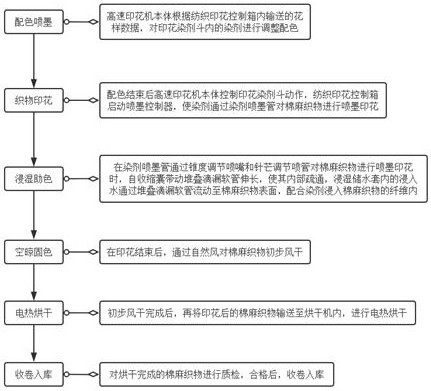

[0061] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to figure 2 A high-speed textile printing machine printing process for cotton and linen fabrics, comprising the steps of:

[0062] S1. Color matching inkjet: the high-speed printing machine body 1 adjusts the color matching of the dye in the printing dye bucket 3 according to the pattern data conveyed in the textile printing control box 2;

[0063] S2. Fabric printing: After the color matching is completed, the high-speed printing machine body 1 controls the action of the printing dye hopper 3, and the textile printing control box 2 starts the inkjet controller 4, so that the dye is sprayed on the cotton and linen fabric through the dye inkjet tube 301 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com