Double-contact-line integral suspension type sling assembly

A double-contact, suspended technology, applied in overhead lines and other directions, can solve high-level problems such as many components, increased operation and maintenance workload, and difficulty in ensuring the distance between contact lines and two contact lines. Stream quality, improved stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

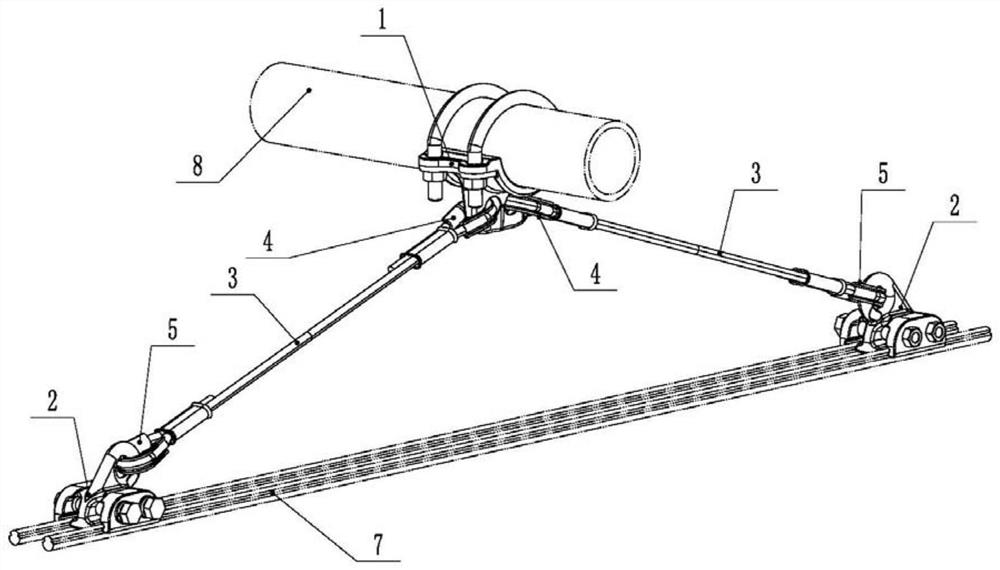

[0017] Attached below Figure 1-5 The present invention will be described in detail with specific embodiments.

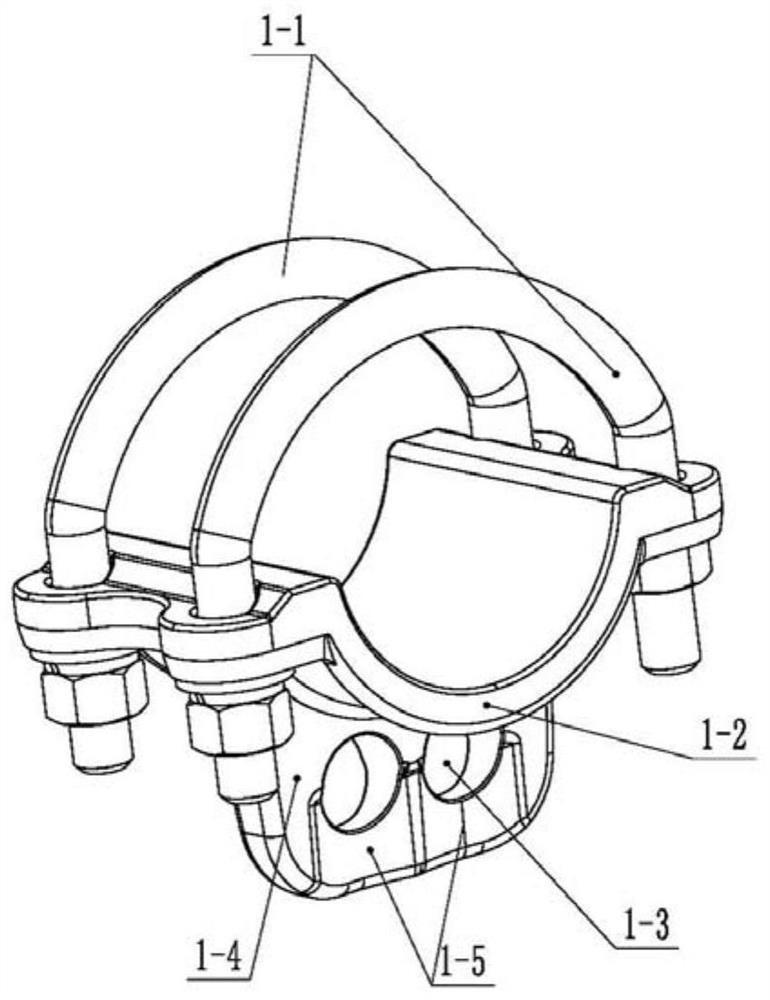

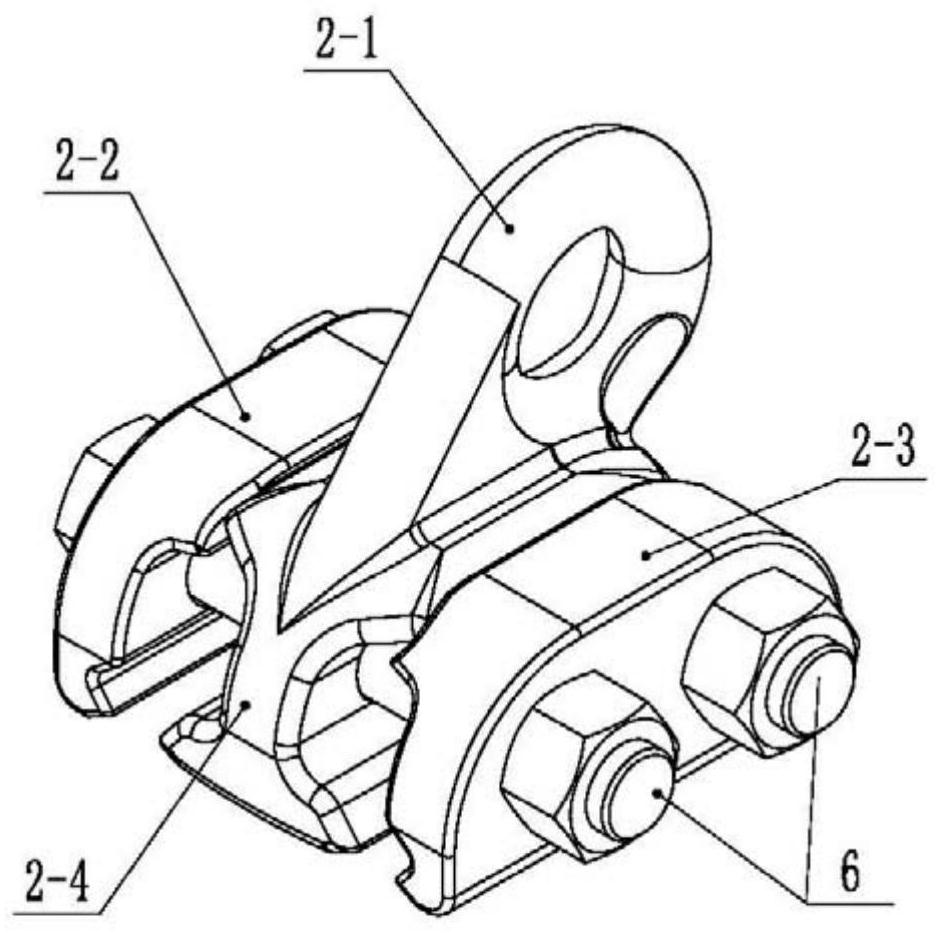

[0018] A double contact wire integral suspension type sling assembly, comprising a sling fixing seat 1, a double contact wire suspension clamp 2, and a sling stay wire 3, the sling fixing seat 1 is composed of a U-shaped bolt pair 1-1 and a half-embracing The hoop body 1-2 is connected, and the bottom of the half hoop body 1-2 has a first single ear 1-4 along the line direction, and the first single ear 1-4 has two first connection holes side by side 1-3; the double contact line suspension clamp 2 includes a left splint 2-2, a middle splint 2-4 and a right splint 2-3, and the middle splint 2-4 has a second single ear along the line direction above it 2-1, and the second single ear 2-1 has a second connection hole 2-1-1, and both sides of the bottom of the middle splint 2-4 have first tooth-shaped bosses 2-5 along the line direction ; The left splint 2-2 has the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com