Rapidly buildable movable sandwich layer structure of sandwich board and its expansion method

A sandwich panel and expansion method technology, applied in building components, building structures, buildings, etc., can solve problems such as poor load-bearing capacity, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above-mentioned features and advantages of the present invention easier to understand, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

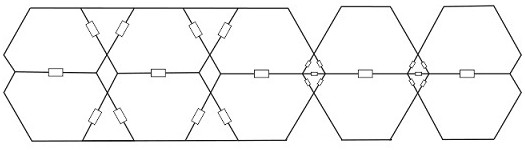

[0027] refer to Figure 1 to Figure 8

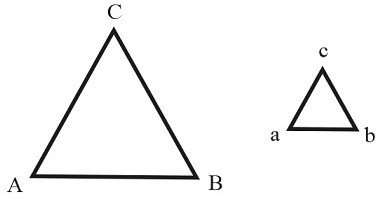

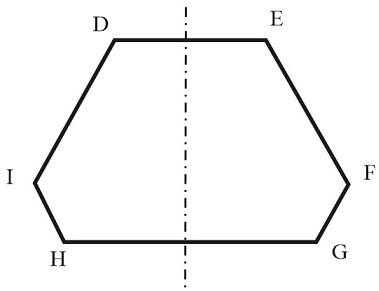

[0028] A movable sandwich layer structure of a sandwich board that can be quickly built, including several isosceles triangular modules Ⅰ, isosceles triangular modules Ⅱ and hexagonal modules with 4 connecting sides symmetrical to each other, isosceles triangular modules Ⅰ and isosceles triangular modules Module II is a similar triangle.

[0029] The isosceles triangle module has bottom connection side, left waist connection side, and right waist connection side. The angle between the edge and the bottom connecting edge is the right bottom angle. There are upper bottom connecting edge and lower bottom connecting edge in the hexagonal module, the sides adjacent to the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com