Knotted temporary plugging ball for staged fracturing in oil and gas fields, method and application

A technology of temporarily blocking balls and knots, which is applied in the direction of earthwork drilling, wellbore/well components, and production fluids, etc. High sealing efficiency, improved sealing effect, and improved production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

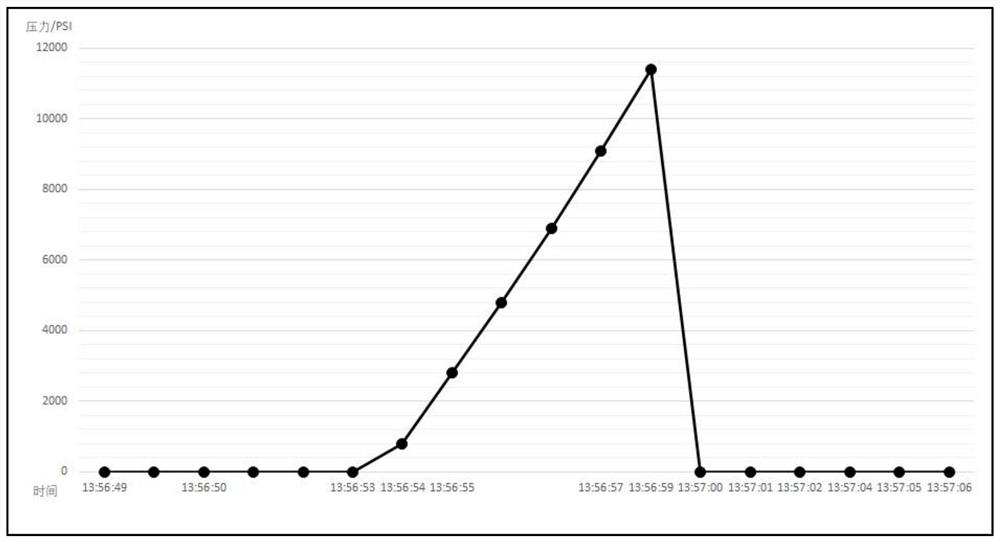

Image

Examples

preparation example Construction

[0043] The above-mentioned preparation method of the knotted temporary plugging ball for staged fracturing in oil and gas fields, the steps are as follows:

[0044] Put the knot ball body into the ball grinder, pour the mixture of ethylene glycol, paraffin, and NP-30 melted at 70 °C, the mass ratio of the three is 7:1:2, and it is obtained after cooling. The knot temporarily blocks the ball.

[0045] The body of the knotted temporary blocking ball is wrapped into a spherical shape with a mixture of polyethylene glycol, paraffin, and NP-30 to ensure that the ball is thrown smoothly through the manifold to reach the blasthole position. The wrapping shell will dissolve quickly in the wellbore, and the shell will be broken after entering the blasthole, and the temporary blocking ball of the knot will be released to effectively block the blasthole.

[0046] The above-mentioned method for using the knotted temporary plugging ball for staged fracturing in oil and gas fields, the ste...

Embodiment 1

[0052] Preparation process of temporary blocking ball: Take the preparation of 20mm knotted temporary blocking ball suitable for 95℃ as an example:

[0053] Cut 160mm composite polyvinyl alcohol fiber, weigh 8g, wind the fiber longitudinally for 2 turns, wind it horizontally for 2 turns, pass through the upper and lower rope buckles for 2 turns, and tighten the two ends of the fiber to form a knot and temporarily block the ball. Put the knot temporarily blocking ball into a ball grinder with a diameter of 30mm, pour the mixture of ethylene glycol, paraffin, and NP-30 (mass ratio is 7:1:2) that has been melted at 70 °C. To temporarily block the ball.

Embodiment 2

[0055] Take the preparation of 22mm knotted temporary blocking ball suitable for 70℃ as an example:

[0056] Cut 200mm composite polyvinyl alcohol fiber, weigh 12g, wind the fiber longitudinally for 2 turns, wind it horizontally for 2 turns, pass through the upper and lower two rope buckles and wind it for 2 turns, and tighten the two ends of the fiber to form a knot and temporarily block the ball. Put the knot temporary blocking ball into a ball grinder with a diameter of 30mm, pour the mixture of polyethylene glycol, paraffin, and NP-30 (mass ratio is 7:1:2) melted at 70 ℃. After cooling That is, the temporary blocking of the ball.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com