Equipment system and method for improving quality of powder bed in additive manufacturing process

A technology of additive manufacturing and equipment, which is applied in the field of processing workpieces with complex structures formed by equipment, and can solve problems such as deviation from expected size requirements, deformation, and failure to achieve expected molding quality effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

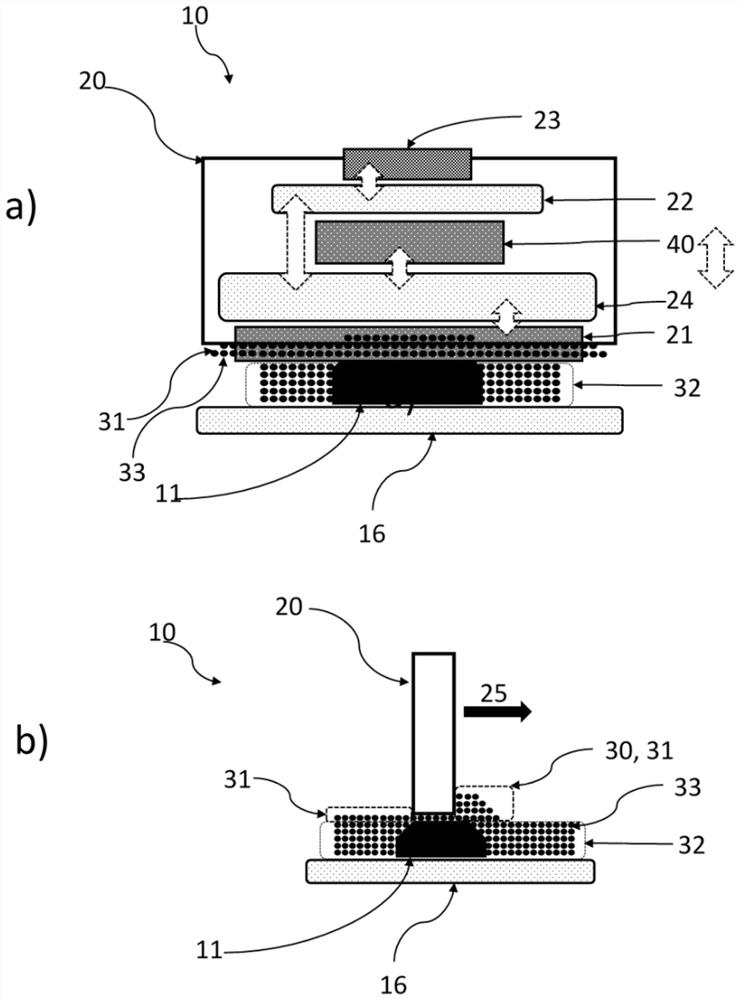

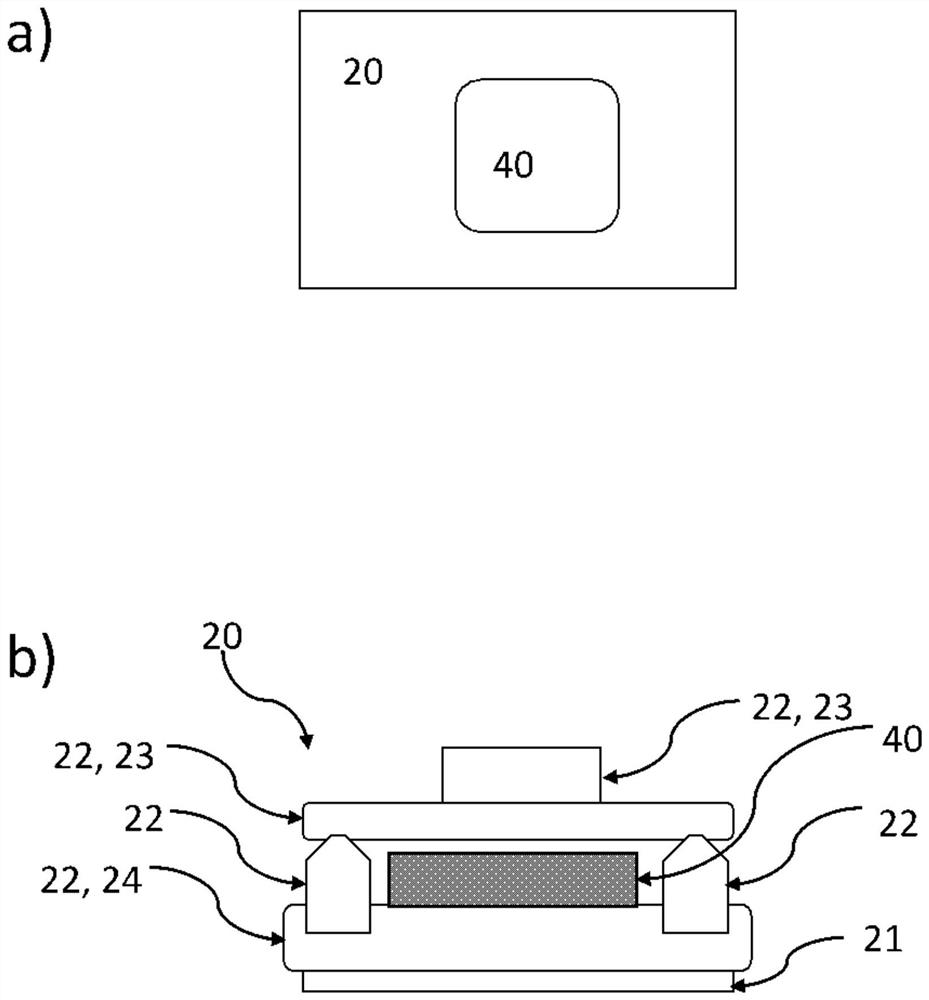

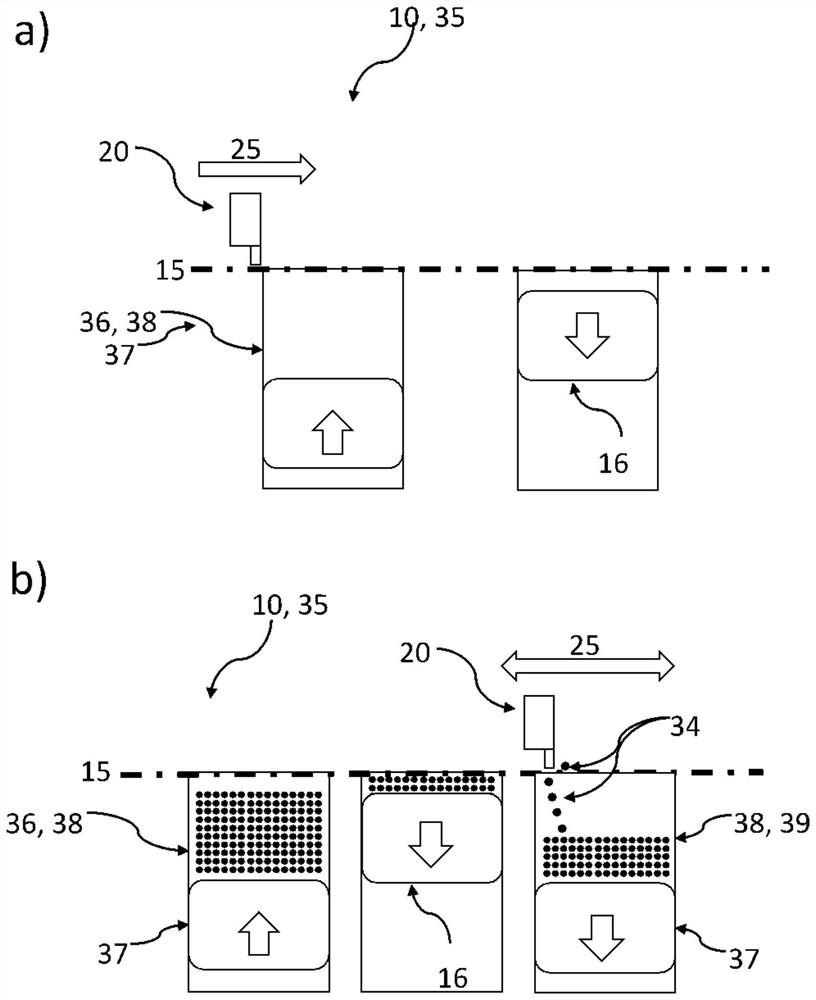

[0047] Refer below Figures 1 to 7 Exemplary embodiments of the invention are described in detail, without prejudgment, and especially without limitation. Unless otherwise stated, identical elements are provided with identical reference numerals.

[0048] figure 1 a) shows the system 10 according to the invention during the spreading of the powder 30 by means of the spreading device 20 . The system 10 according to the invention is suitable for the additive production of complex structural workpieces 11 and comprises a spatially displaceable powder spreading device 20 for powder 30 which also comprises an excitation unit 40 .

[0049] The powder spreading device 20 is used to convey one or more powder layers 31 on the processing plane 15 to the substrate platform 16 or to a previously processed powder bed 32 .

[0050] The excitation unit 40 is configured to break up the clusters and / or adhesions of the powder particles 33 with each other and / or with the powder bed 32 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com