Powder system device and method for improving powder utilization efficiency of additive manufacturing process

A technology of additive manufacturing and powder spreading device, which is applied in the direction of improving process efficiency, manufacturing auxiliary devices, manufacturing tools, etc., can solve the problems that powder cannot be used for production, increase processing cost, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

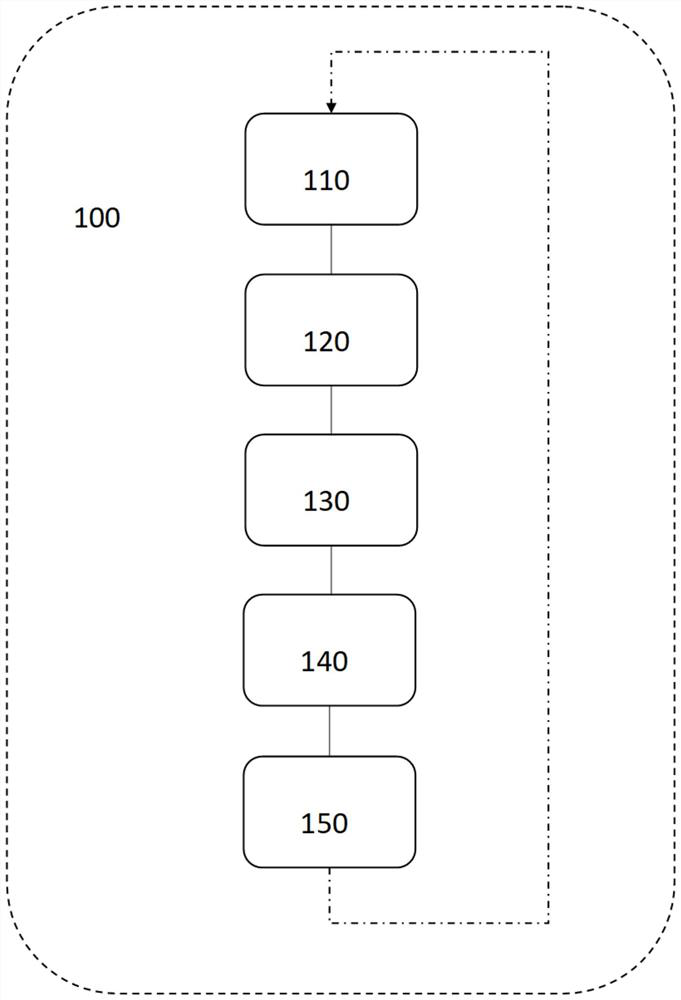

[0041] Refer below Figures 1 to 5 Exemplary embodiments of the invention are described in detail, without prejudgment, and especially without limitation. Unless otherwise stated, identical elements are provided with identical reference numerals.

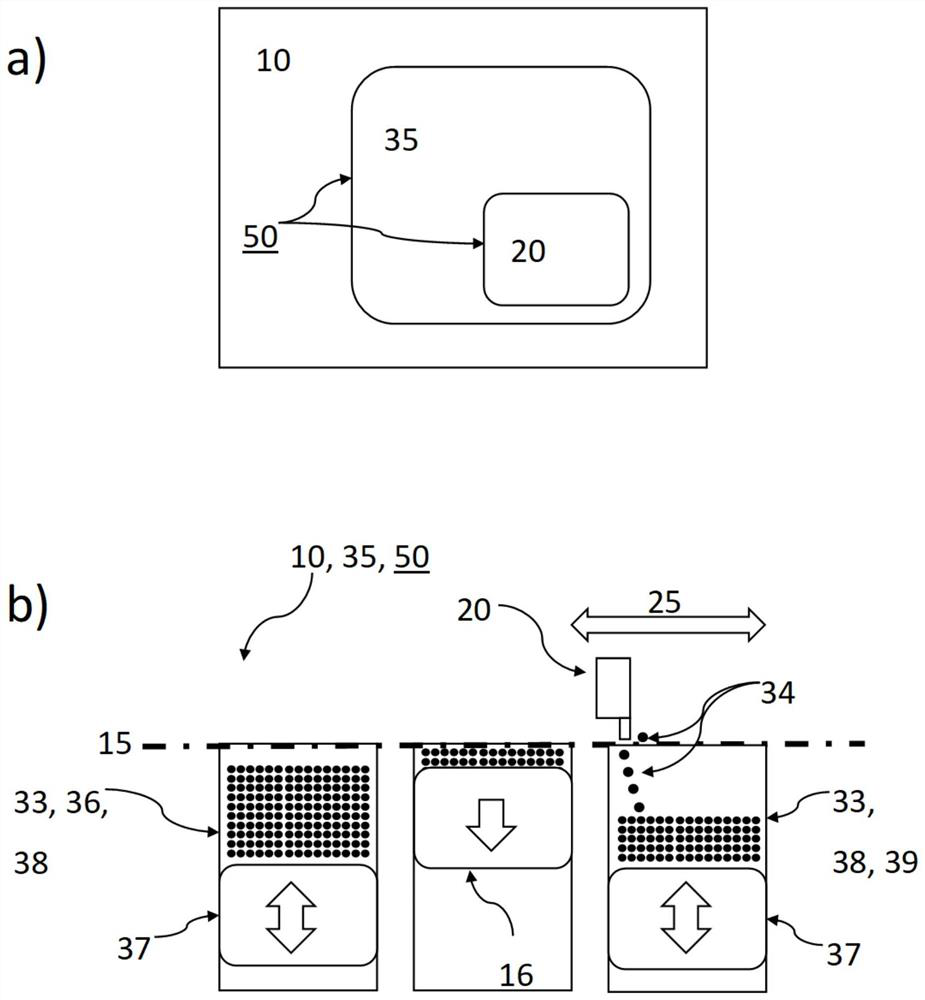

[0042] figure 1 a) and b) show the equipment system 10 suitable for the additive manufacturing process technology of complex structural workpieces introduced according to the present invention, including a space-movable powder spreading device 20 for powder, and a powder system for providing powder 35, and a control unit 50 for controlling at least the powder spreading device 20 and the powder system 35.

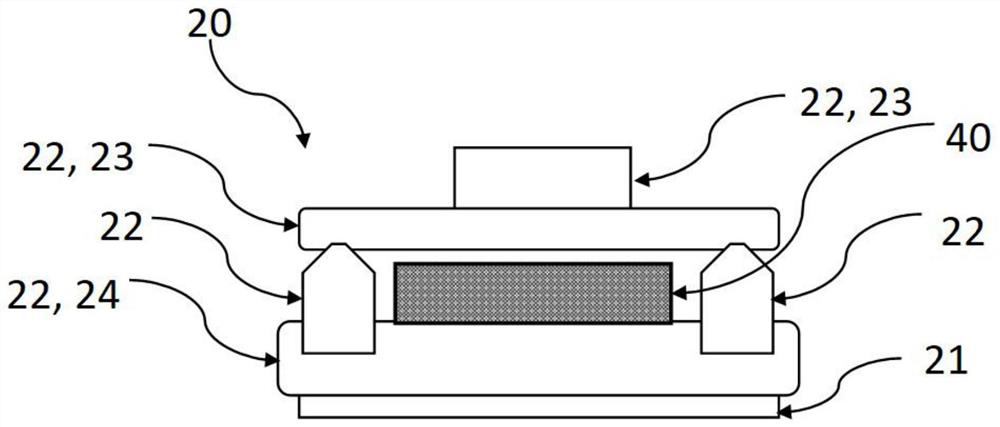

[0043] The powder spreading device 20 is used to transfer one or more layers of powder on the processing plane 15 to the substrate platform 16 , or to an already processed powder layer.

[0044] The powder system 35 includes at least a first powder container 36 and a second powder container 39, which are alternately arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com