Floating brake disc performance testing device and method with environment simulation box

A technology of environmental simulation and testing equipment, which is applied in the direction of measuring equipment, vehicle testing, and mechanical component testing, etc., and can solve the problems of lack of floating brake disc performance testing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

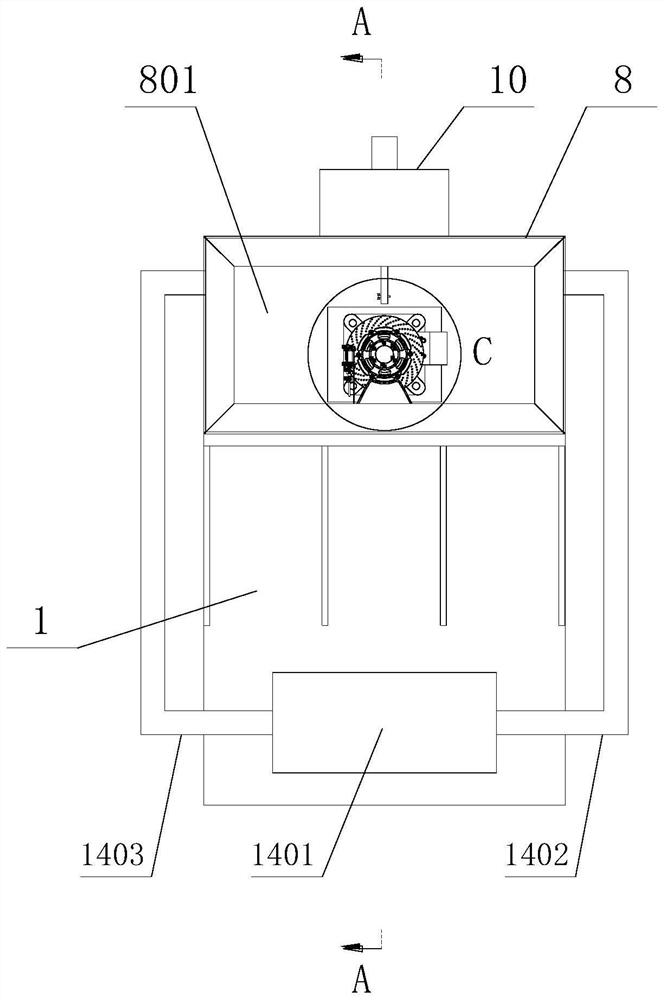

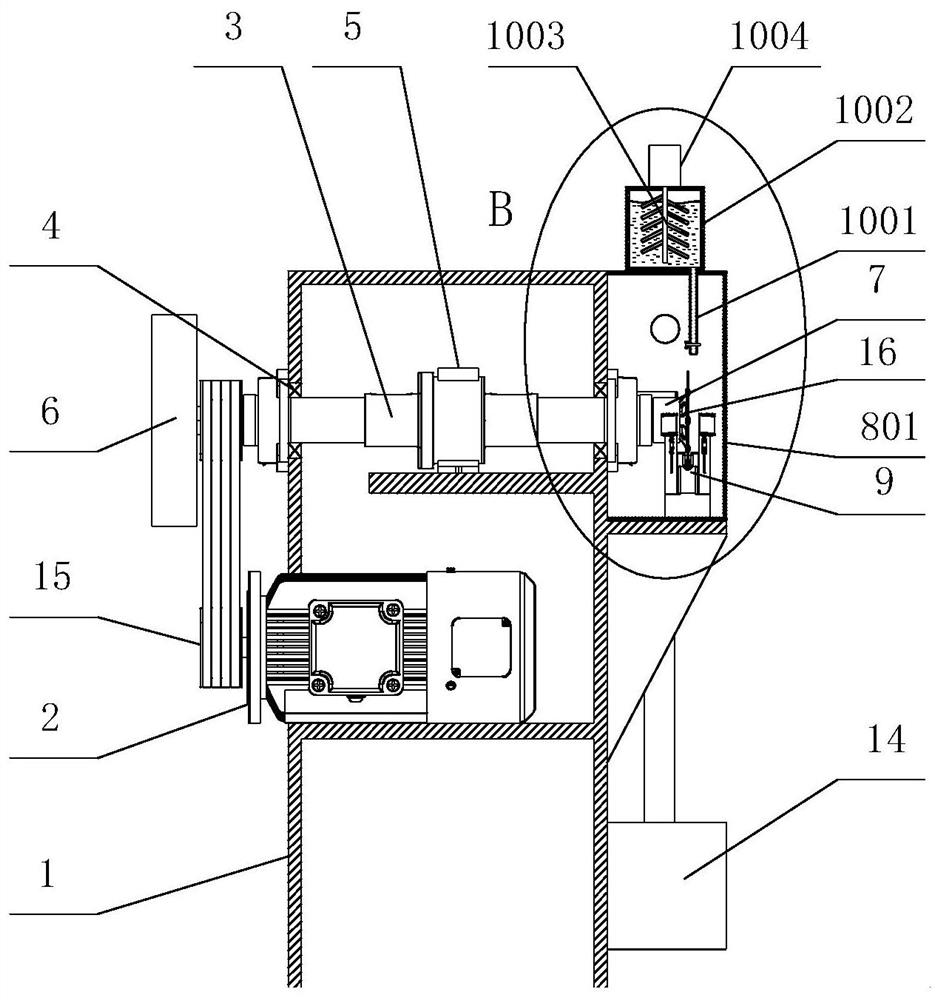

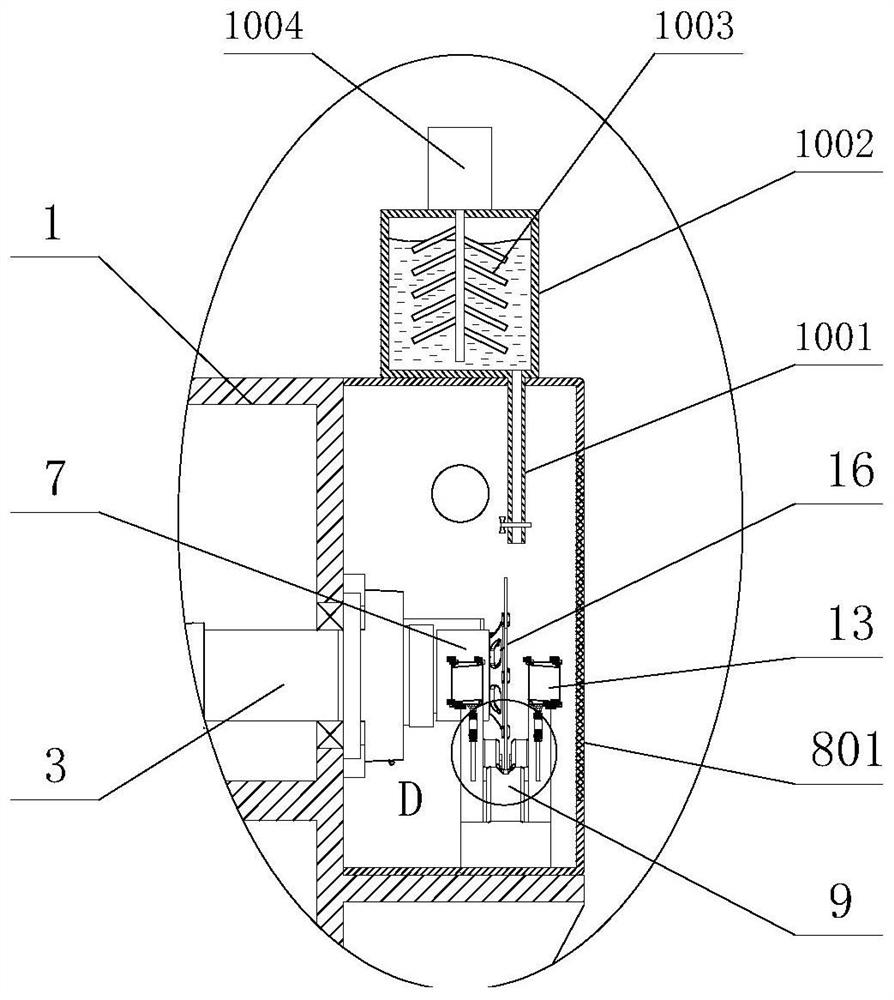

[0028] see Figure 1-5 , the floating brake disc performance testing device with environmental simulation box of the present invention comprises a body 1, a motor 2 is installed on the body 1, the motor 2 and a transmission shaft 3 form a transmission structure, and the transmission shaft 3 passes through a bearing 4 Installed on the body 1, a torque sensor 5 is installed on the transmission shaft 3, and a flywheel 6 is installed at one end of the transmission shaft (in this embodiment, the moment of inertia of the flywheel is 1.43kg m 2 ), the other end is equipped with a flange 7, and the flange 7 is used to fix the floating brake disc 16; the flange 7 is arranged in the environmental simulation box 8, and the corresponding brake 9 and a spraying device 10, the brake 9 is arranged under the flange 7, and a displacement sensor 11, a temperature sensor 12 and a speed sensor 13 are correspondingly arranged beside the brake 9, and the outside of the environment simulation box 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com