2. N-dimensional oil reservoir chip and manufacturing method thereof

A manufacturing method and chip technology, which are applied in chemical instruments and methods, preparation of test samples, measuring devices, etc., can solve the problems of small distribution range, flow difference, inability to occur multiphase seepage of three-dimensional cores, etc. The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] A method for making a reservoir chip, comprising:

[0065] (1) Select the real oil reservoir core of Changqing Oilfield, and use micro-CT to scan the three-dimensional structure of the real oil reservoir core;

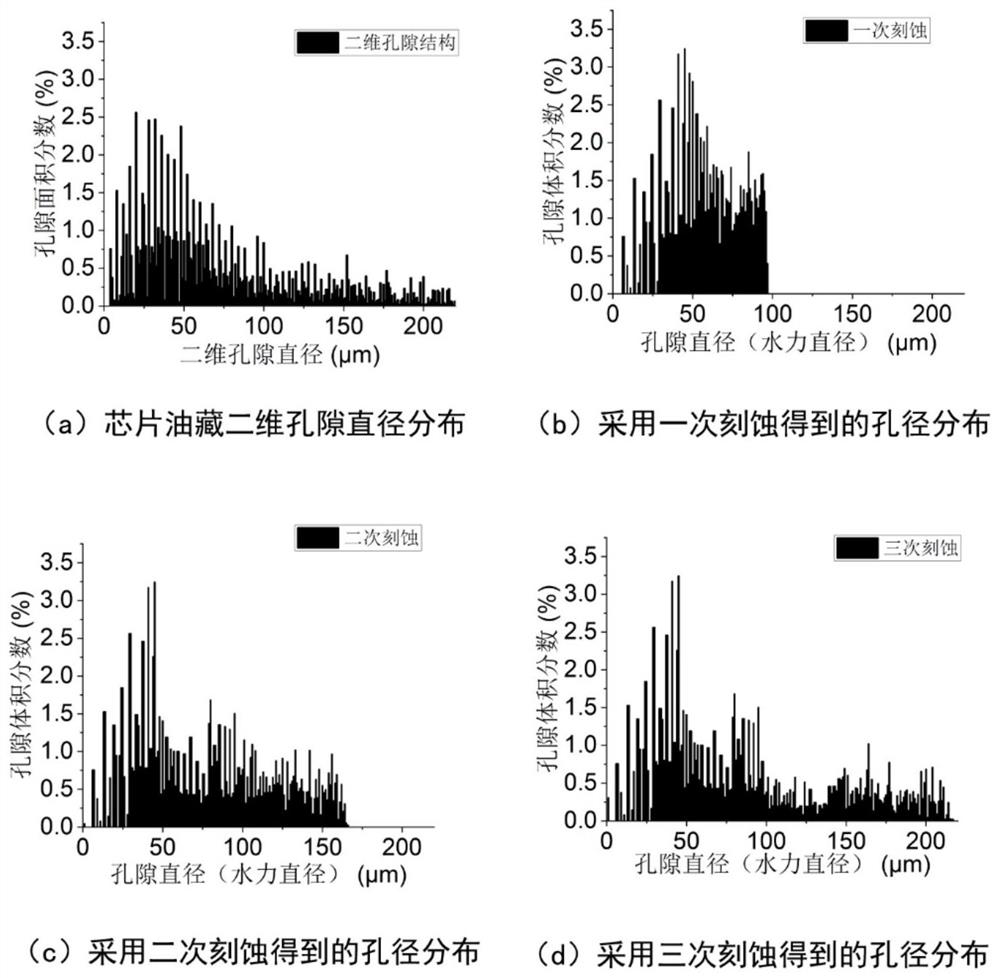

[0066] (2) Using matlab or imageJ software to reconstruct the three-dimensional structure of the real reservoir core obtained by scanning, and extracting the pore size distribution characteristics by the maximum sphere method;

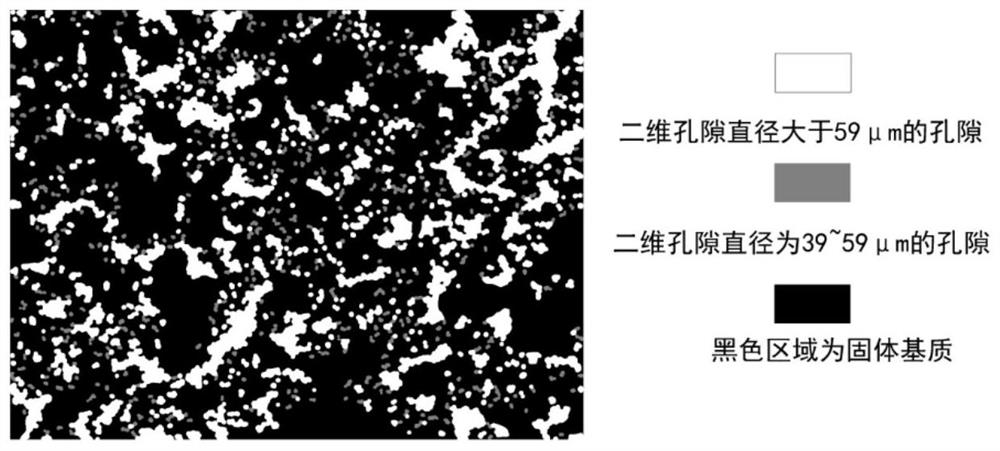

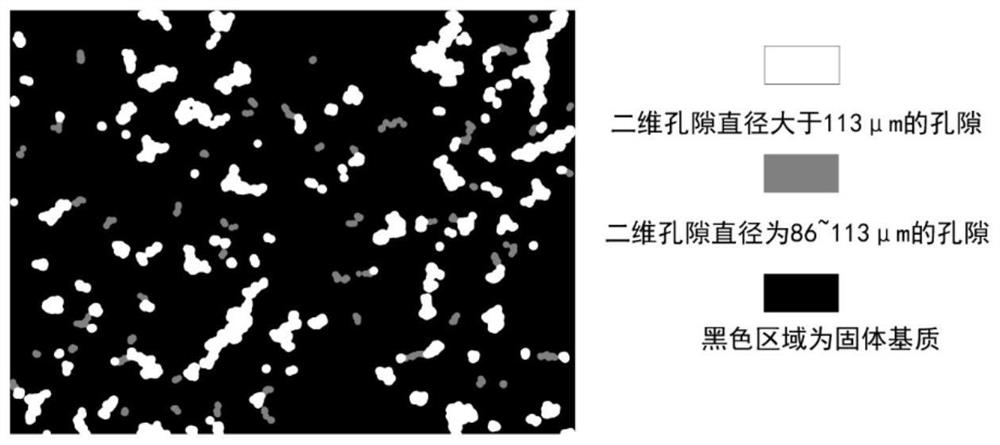

[0067] (3) According to the obtained pore size distribution characteristics, the formation of the pore structure of the real oil reservoir core and the accumulation form of rock particles are analyzed, and the main large particles (referring to volume accounting for the entire rock solid matrix) in the rock particles are extracted. Particles whose volume is more than 1% of the volume), and establish a large particle morphology database;

[0068] (4) using a four-parameter random generation method to randomly select a number of large par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com