Portable intelligent synchronous near control device for hot rolling finishing operation line

An operation line and portable technology, applied in the field of portable intelligent synchronous proximity control devices for hot rolling finishing operation lines, can solve the problems of long occupation time, impossible function expansion, large amount of cables, etc., and save engineering costs and hardware. Consistent effect of input and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

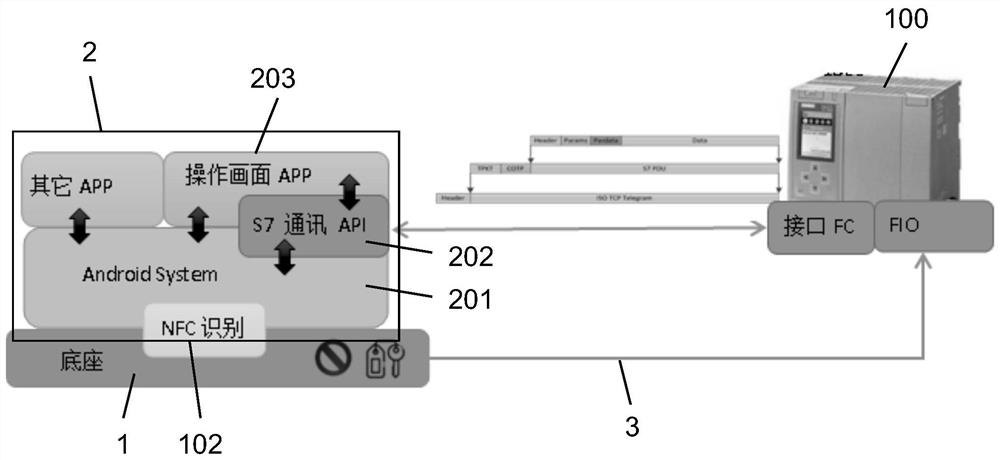

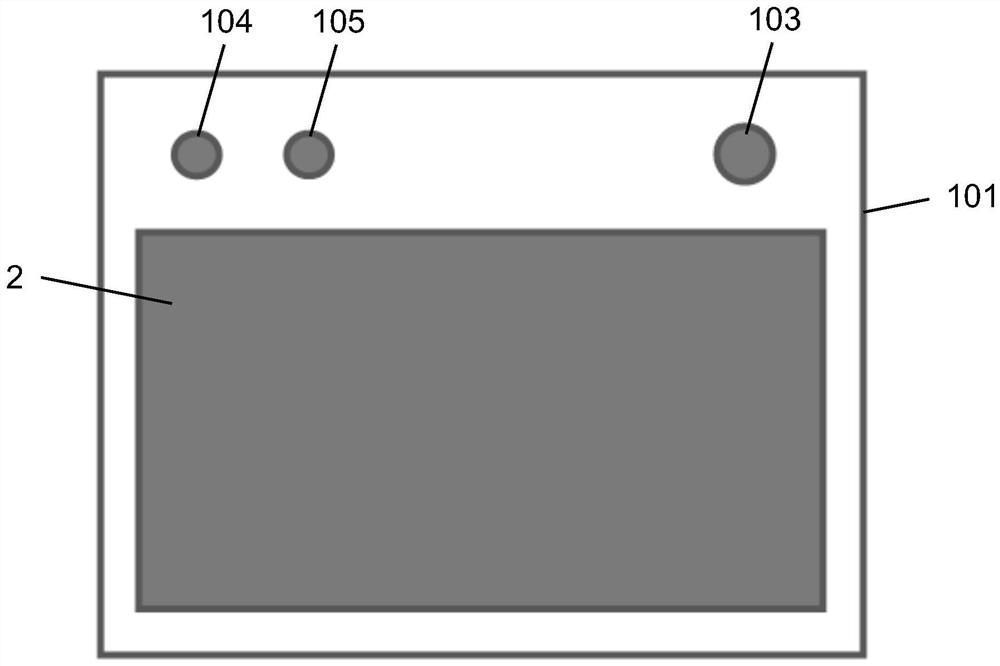

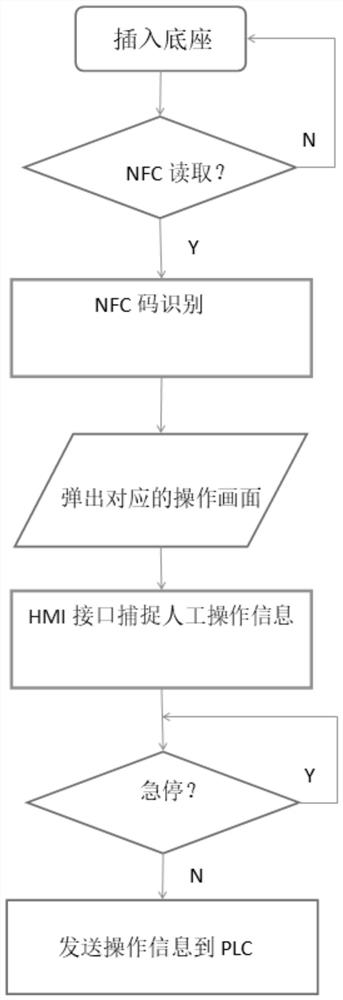

[0046] Such as figure 1 and figure 2 As shown, a portable intelligent synchronous proximity control device for a hot-rolling finishing line provided by the present invention establishes a communication connection with the S7 PLC100 of the finishing line. Multiple industrial intelligent panel bases 1 next to the regional machine, and an industrial intelligent panel 2 that can be inserted into any industrial intelligent panel base 1. When near-control operation near the machine is required, the operator carries the industrial smart panel 2 to the industrial smart panel base 1 next to the machine in the corresponding process area, inserts and fixes the industrial smart panel 2 onto the industrial smart panel base 1 for close-control operation, and operates After finishing, remove the industrial smart panel 2 and bring it back....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com