Workpiece cleaning device

A technology for cleaning devices and workpieces, applied in the direction of cleaning methods using tools, electrical components, cleaning methods and utensils, etc., can solve problems such as long processing time, inability to improve manufacturing efficiency, etc. The effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

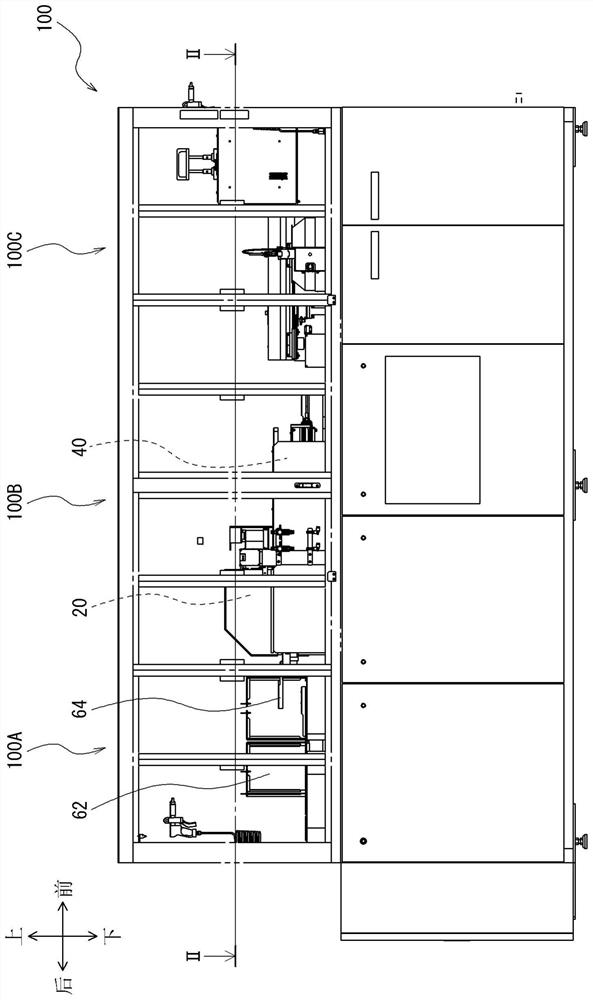

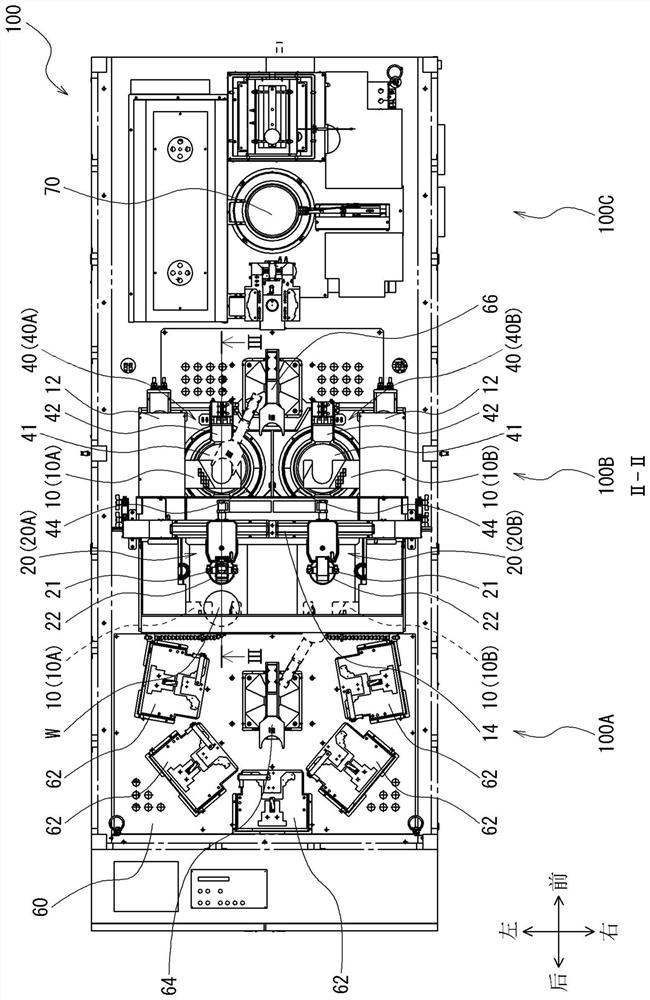

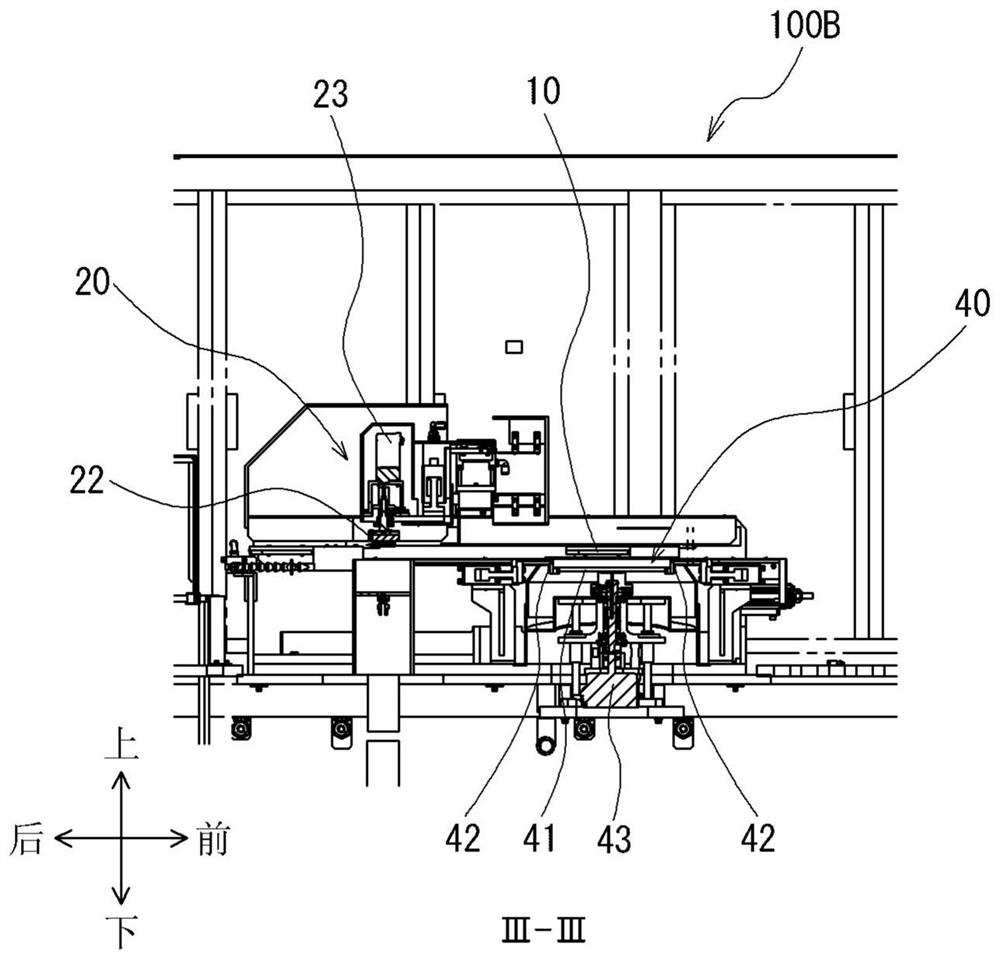

[0016] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a schematic diagram (side view) showing an example of the workpiece cleaning device 100 according to the embodiment of the present invention. in addition, figure 2 yes figure 1 The II-II line sectional view in, image 3 yes figure 2 Sectional view of line III-III in. In addition, for convenience of explanation, the directions of front and rear, left and right, and up and down in the workpiece cleaning device 100 may be described by arrows in the drawings. In addition, in all the drawings for explaining the respective embodiments, members having the same functions are denoted by the same reference numerals, and overlapping description thereof may be omitted.

[0017] The workpiece cleaning device 100 of the present embodiment is a device for cleaning a flat workpiece W. As shown in FIG. As this workpiece W, a disk-shaped wafer (silicon wafe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com