Atomization dust removal equipment convenient to clean in multiple directions and used for building construction

A technology for building construction and dust removal equipment, which is applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of small spray area, unsatisfactory dust removal effect of fog cannons, and single function, and achieves simple operation, Improve the effect and efficiency of atomization and dust removal, and the effect of novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

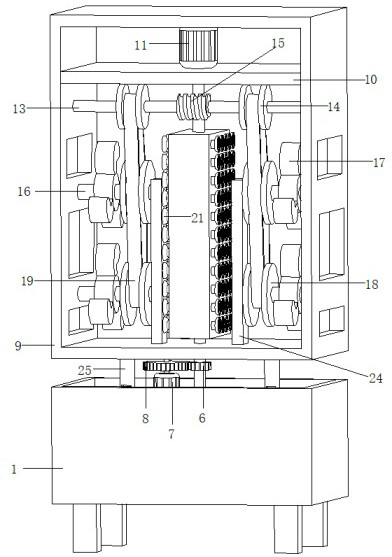

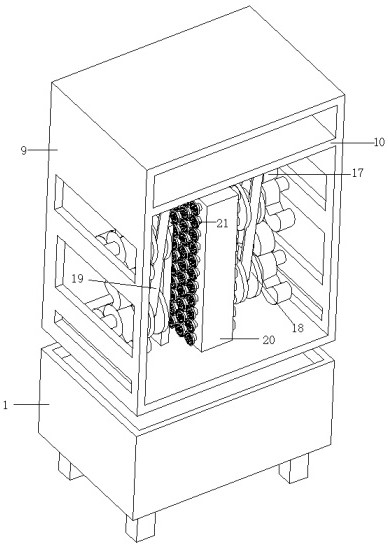

[0026] refer to figure 1 , image 3 , Figure 5 A kind of atomization dedusting equipment for building construction that is convenient for multi-directional cleaning, including a base 1, is characterized in that, the inside of the base 1 is provided with a water reservoir, the inside of the reservoir is provided with a water inlet mechanism, and the top of the base 1 A rotating mechanism is provided, a body 9 is arranged above the rotating mechanism, and a transmission mechanism and an atomizing mechanism are arranged inside the body 9 .

[0027] In the present invention, the water inlet mechanism communicates with the atomization mechanism, and the water inlet mechanism includes a water pump 2 fixedly connected to the water reservoir. The upper end of the water pump 2 is provided with a water pipe 3, and a return water dripping plate 4 is fixedly connected above the water reservoir. The clean water in the reservoir is adsorbed upward through the water pipe 3 through the wat...

Embodiment 2

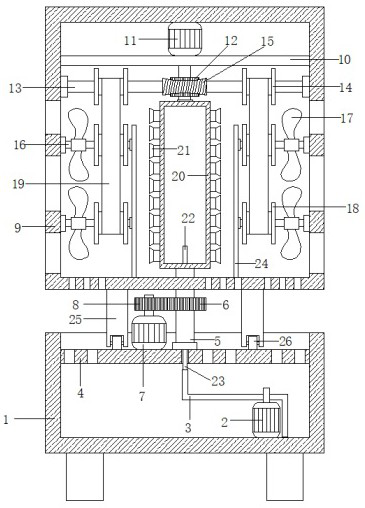

[0031] refer to figure 2 , Figure 4 , Image 6 : A kind of atomization dedusting equipment for building construction that is convenient for multi-directional cleaning. In the present embodiment, the transmission mechanism includes a support plate 10 that is fixedly connected with the body 9, and the top of the support plate 10 is fixedly connected with the second motor 11. The second motor The output shaft of 11 is fixedly connected with a worm wheel 12, and the upper part of the body 9 is rotatably connected with a transmission rod 13; The first belt pulley 14 is sleeved, and the inner left and right ends of the body 9 are respectively connected with a short shaft 16 for rotation. The belt 19 and the short shaft 16 are respectively fixedly provided with fan blades 17, and the cleaning water sprayed by the shower nozzle 21 is subjected to a large-scale atomization and dust removal treatment through the rotation of the fan blades 17.

[0032] In the present invention, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com