Bending angle adjusting structure and method for steel in production of fire-resisting window

A technology for adjusting the structure and fireproof windows, applied in the directions of forming tools, feeding devices, positioning devices, etc., can solve the problems of easy displacement of steel, difficult to adjust the bending angle, failure of bending, etc., to achieve a wide range of applications, avoid shifting bit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

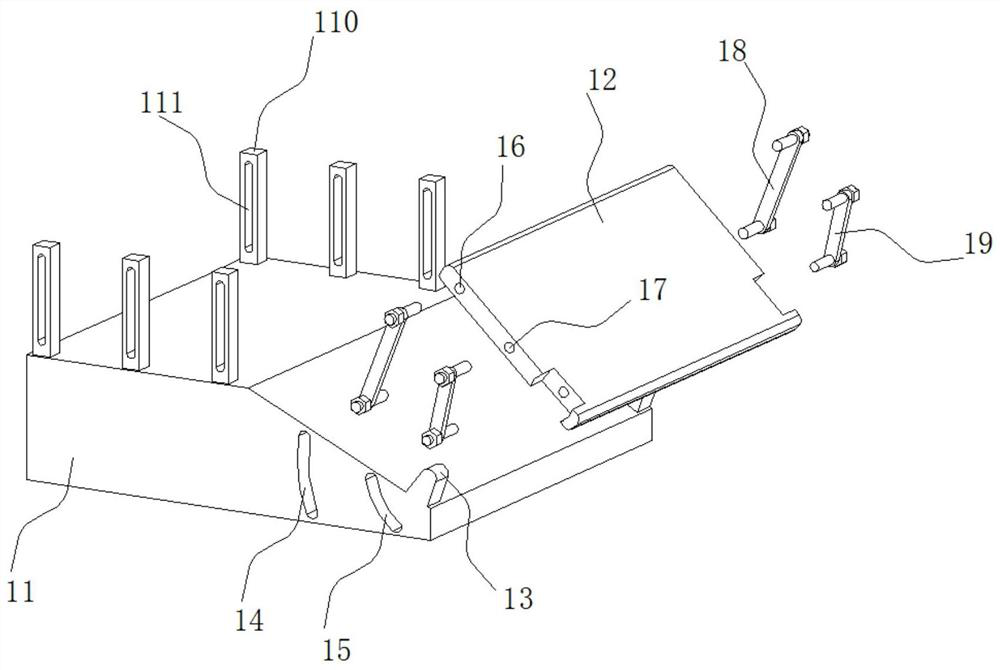

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

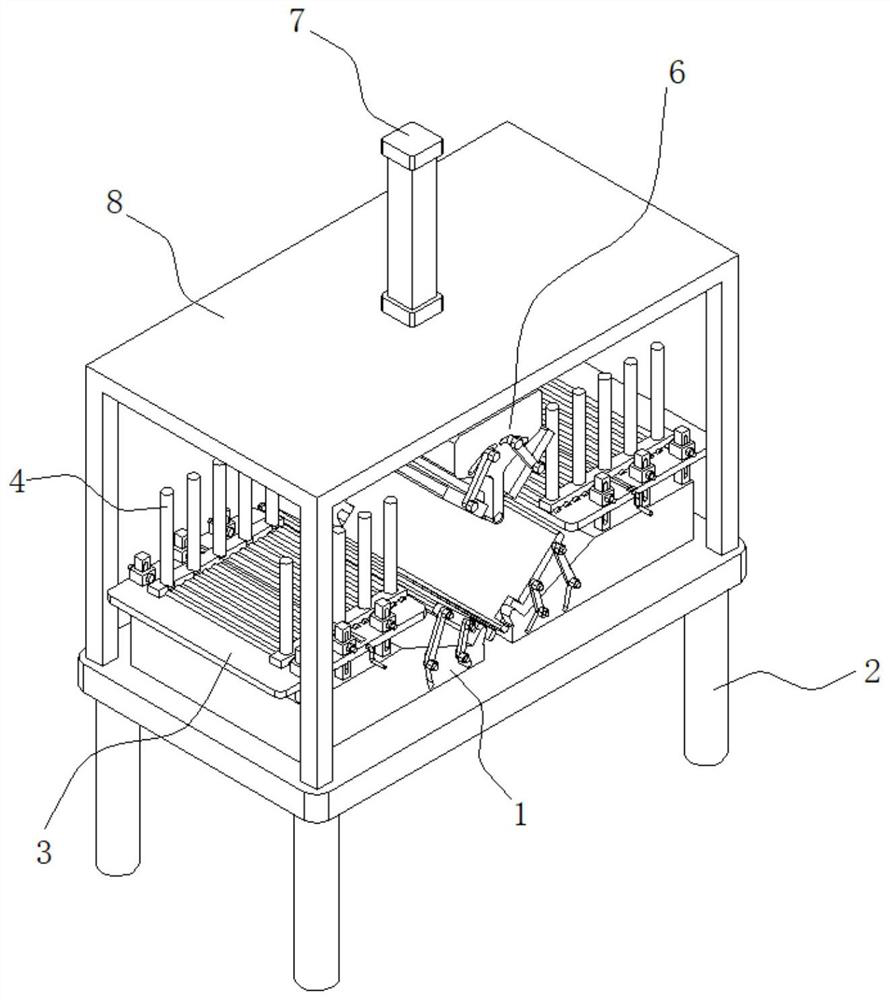

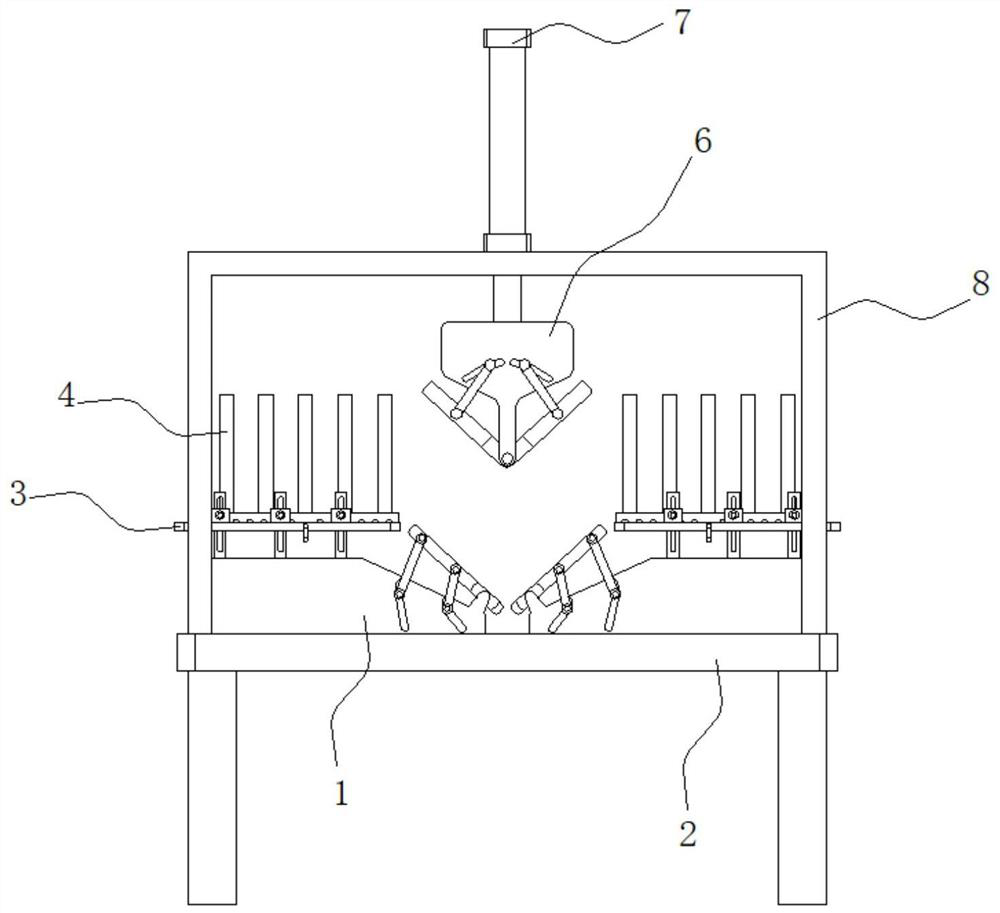

[0041] see Figure 1-2 As shown, the present invention is a bending angle adjustment structure for steel used in the production of fireproof windows, including a bottom bending assembly 1, a support plate 3, a limit mechanism 4, a moving mechanism 5 and a top bending assembly 6, and the top bending assembly 6 The component 6 is fixed on the piston rod of the cylinder 7, the cylinder body of the cylinder 7 is fixed on the top frame 8, the top frame 8 is fixed above the workbench 2, and two symmetrically distributed bottom bends are arranged below the top bending component 6 The folding assembly 1, the bottom bending assembly 1 is fixed on the top of the workbench 2, the upper side of the bottom bending assembly 1 is provided with a support plate 3, and the support plate 3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com