Rivet placing equipment for automatic riveting production line and using method of rivet placing equipment

A production line and rivet technology, applied in the field of rivet placement equipment, can solve problems such as high cost of riveting, reduce the difficulty of riveting, improve the efficiency of riveting, and reduce the cost of riveting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

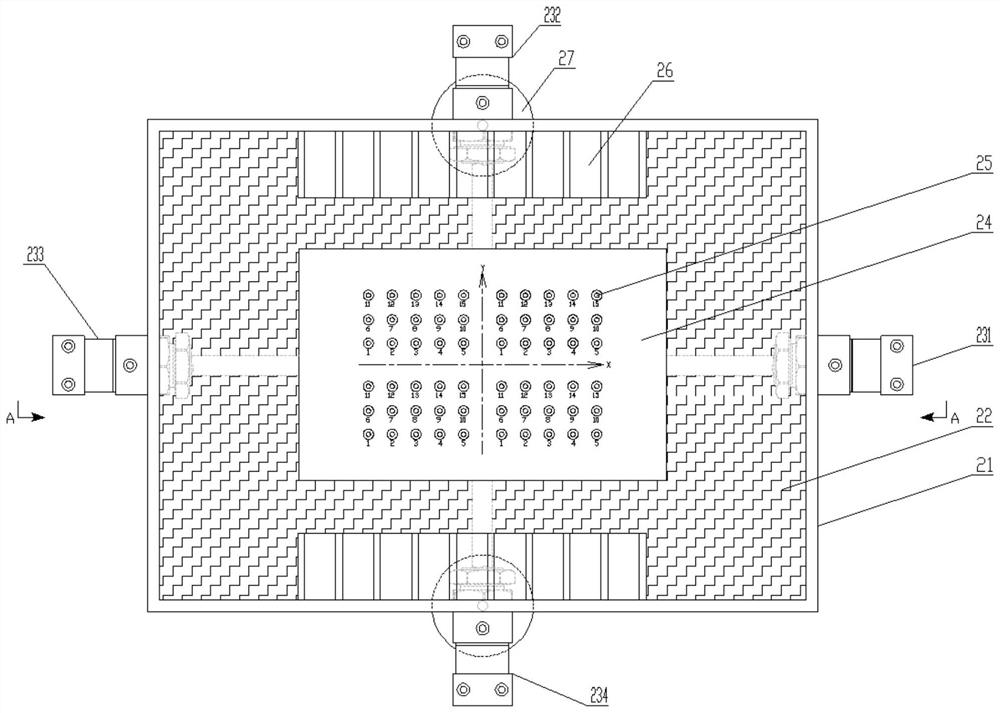

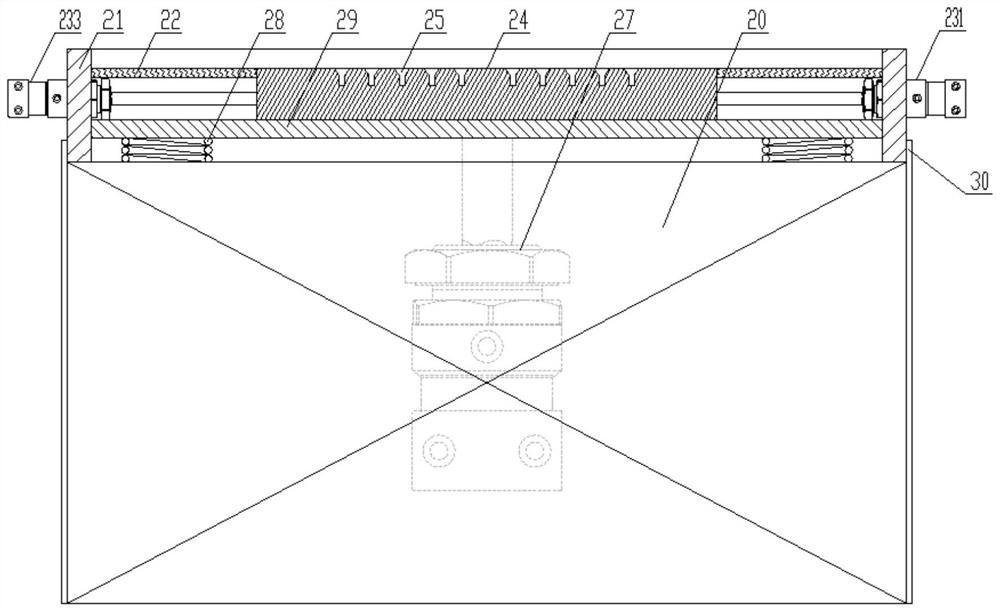

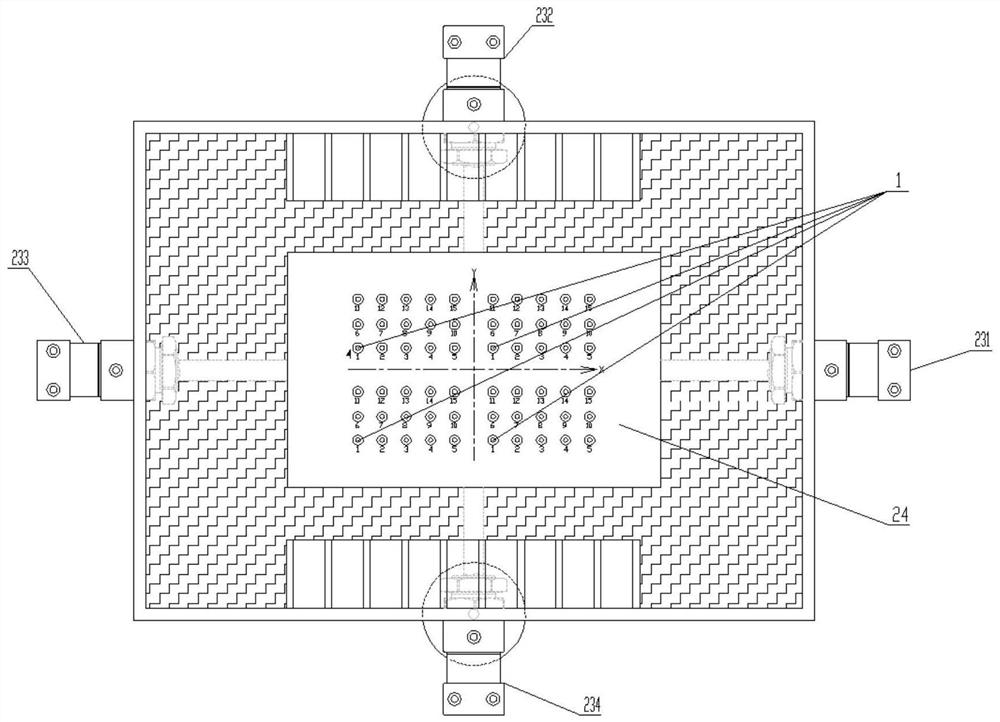

[0026] see figure 1 and figure 2 , a rivet placement device for an automatic riveting production line, including a rivet alignment machine, the rivet alignment machine includes a vibrator 20 and a rivet disc 24 arranged on the vibrator 20, and the rivet disc 24 is arranged with rivet receiving holes 25 in an array , both opposite sides of the rivet disc 24 are provided with guide grooves 26 , and the guide grooves 26 are used to guide the rivets to move onto the rivet disc 24 . An elastic bandage 22 with a thickness of 4 mm is arranged on the periphery of the rivet disc 24. One end of the elastic bandage 22 is fixedly connected to the edge of the rivet disc 24, and the other end is fixedly connected to the frame 21 of the rivet alignment machine. Plane; four sides of the rivet disc 24 are provided with cylinders for driving the translation of the rivet disc 24, which are cylinder one 231 on the right side of the frame 21, cylinder two 232 on the rear side of the frame 21, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com