Wall top and wall surface leveling instrument

A top wall, leveling technology, applied in the direction of building, building structure, etc., can solve the problems of small leveling range and low degree of instrument automation, and achieve the effect of large construction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

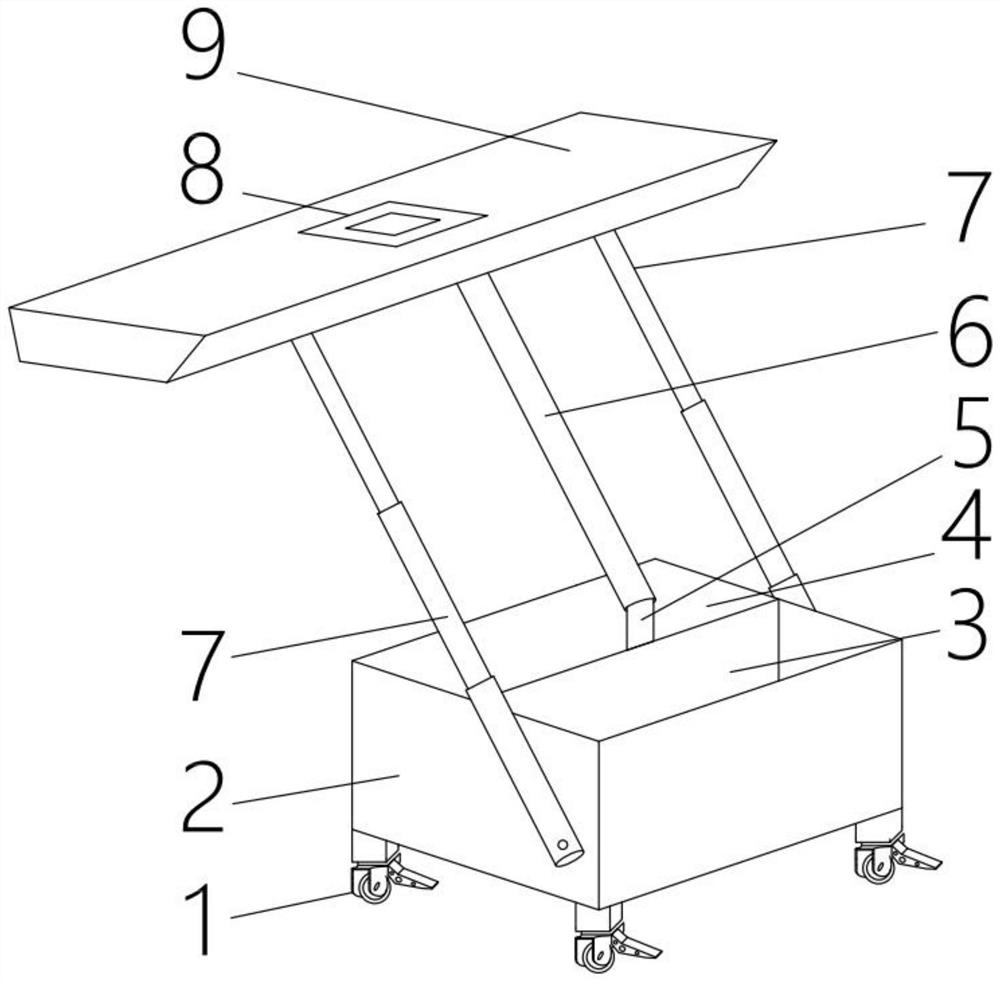

[0029] see figure 1 , the present invention provides the following technical solutions:

[0030] Wall surface leveling instrument on the top of the wall, including universal wheel 1, main box body 2, master control box 3, material box 4, feeding pump 5, feeding pipe 6, telescopic rod 7, leveling knife edge 8, scraper 9, the More than four universal wheels 1 are arranged under the main box body 2, a master control box 3 and a material box 4 are arranged in the main box body 2, a feeding pump 5 is provided at the outlet of the material box 4, and the lower end of the feeding pipe 6 is connected to the material box 4, the upper end is connected to the leveling knife edge 8, and the leveling knife edge 8 is arranged on the scraper 9. The two ends of the scraper 9 are respectively connected to the upper ends of two telescopic rods 7, and the two telescopic rods 7 are axially parallel. Two parallel outer sides of the box body 2.

[0031] Beneficial effects: the instrument is provi...

Embodiment 2

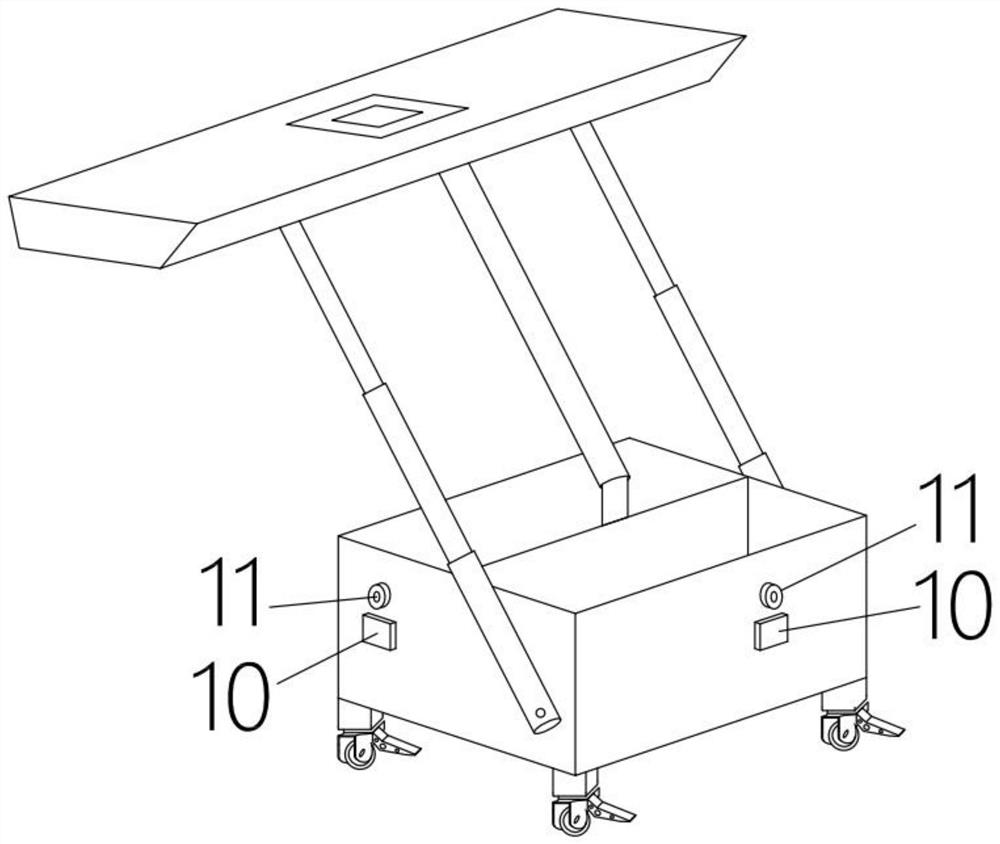

[0033] see figure 2 , the present invention provides the following technical solutions:

[0034] Preferably, as described in Embodiment 1, wall sensors 10 and cameras 11 are provided outside the four sides of the main box body 2 .

[0035] Beneficial effects: the wall sensor 10 and the camera 11 on the outside of the main box 2 cooperate with the master control box 3, so that the instrument can identify the position by itself and perform intelligent control or remote control.

Embodiment 3

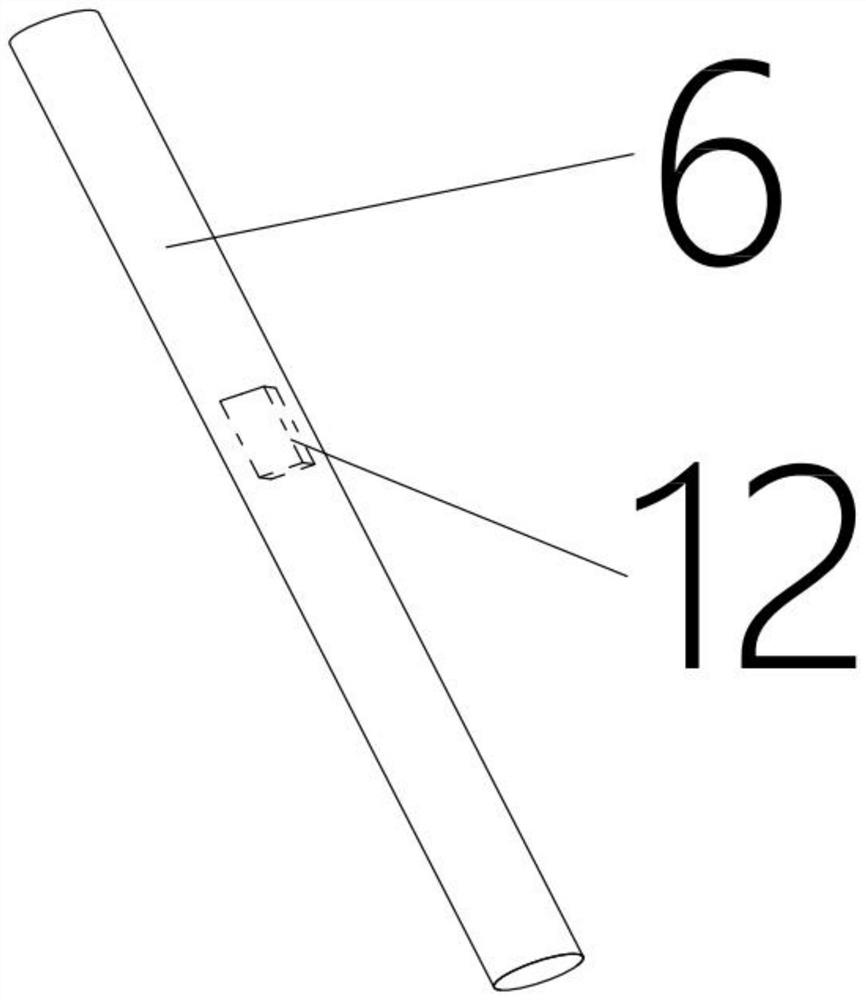

[0037] see image 3 , the present invention provides the following technical solutions:

[0038] Preferably, a pressure controller 12 is provided in the feed pipe 6 as described in Embodiment 2.

[0039] Beneficial effects: the pressure controller 12 in the feeding pipe 6 can detect the pressure in the pipe and regulate the feeding amount and feeding speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com