Construction method for steel sheet pile cofferdam in high-flow-speed sandy gravel area

A technology of steel sheet pile cofferdam and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of increasing construction cost, prolonging construction period, etc., and achieve enhanced stability, improved structural strength, and good social economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS It should be understood that the specific embodiments described herein are intended to illustrate and explain the invention and are not intended to limit the invention.

[0044]In the description of the present invention, it is to be described in that, unless otherwise expressly specified and defined, the term "mount", "connection" should be used to understand, for example, may be a fixed connection, or a detachable connection, or One connection; may be a direct connection, or indirect connection through an intermediate medium, which can be a communication between two components or two components. The specific meaning of the above terms in the present invention can be understood in terms of specific cases.

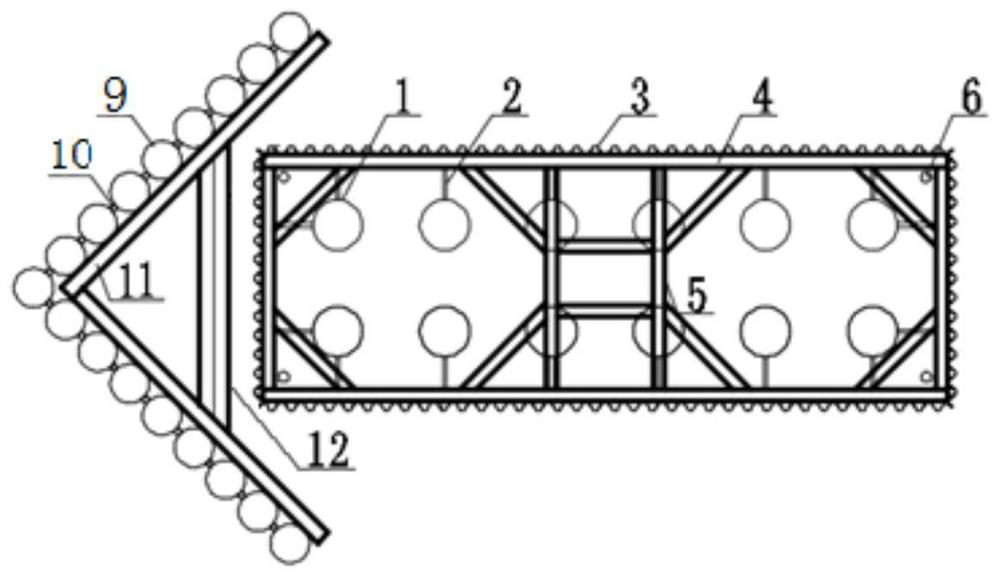

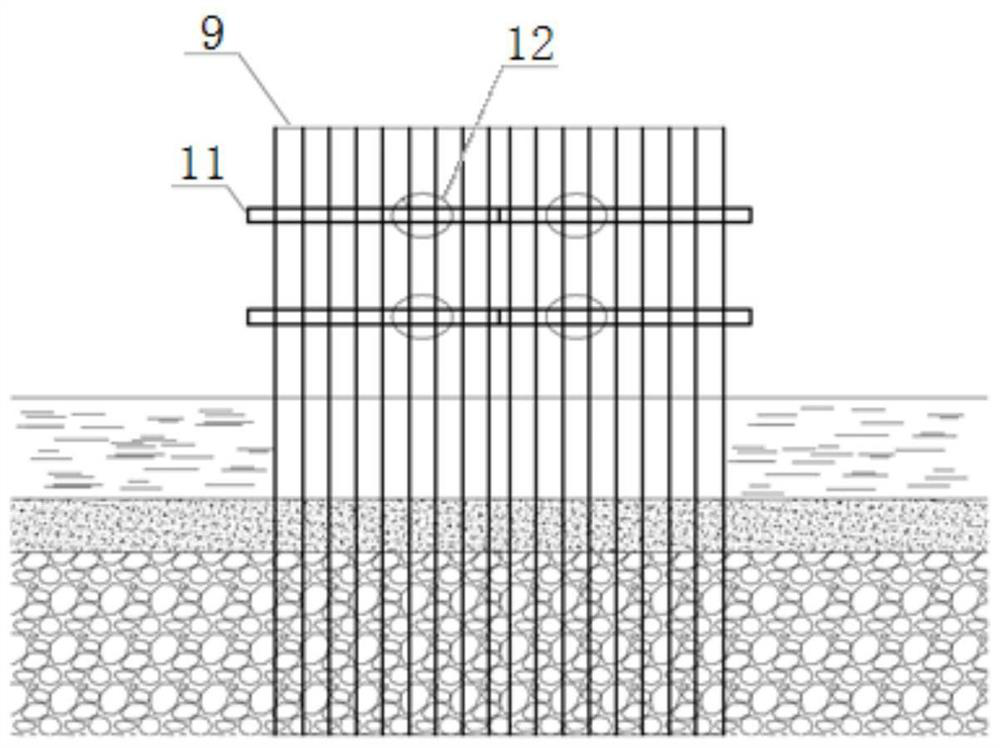

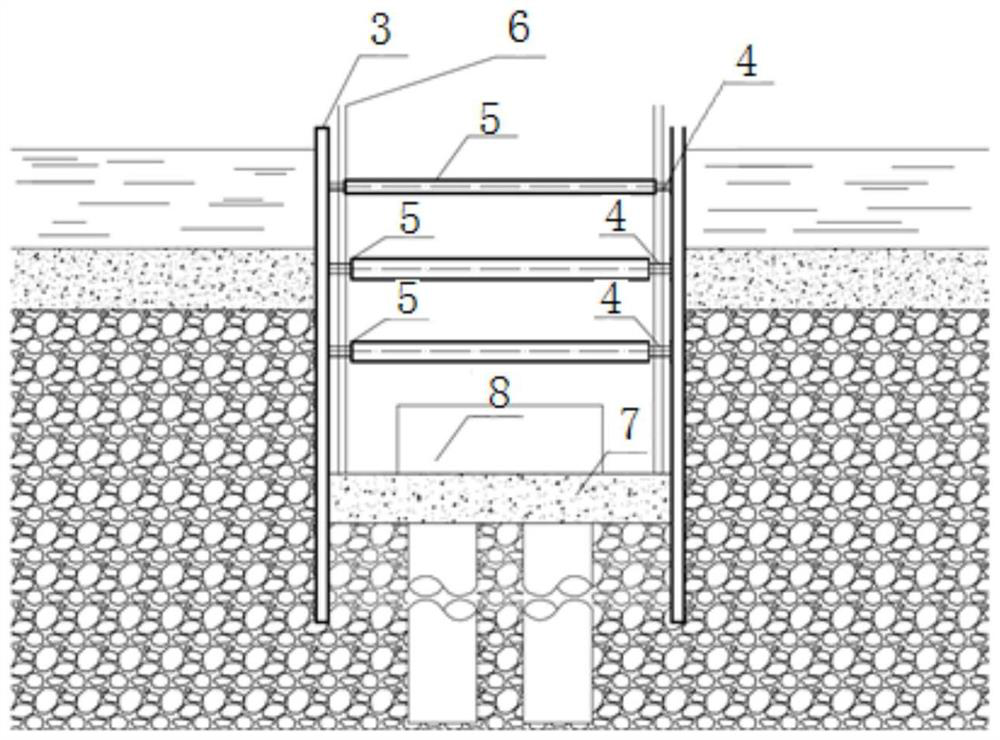

[0045] See Figure 1 to 4 As shown, the steel sheet pile cofferdam construction method of the large-flow rate sand-proof region of the present invention includes the following steps: S1, guide frame positioning: the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com