Polyurethane coating construction base layer treatment agent and polyurethane coating construction base layer treatment method

A technology of polyurethane coating and base treatment agent, applied in the treatment of building materials, coating, marine engineering and other directions, can solve the problems of pinholes and bubbles, difficult construction, etc., achieve simple construction, excellent performance, improve pinholes and The effect of the bubble problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

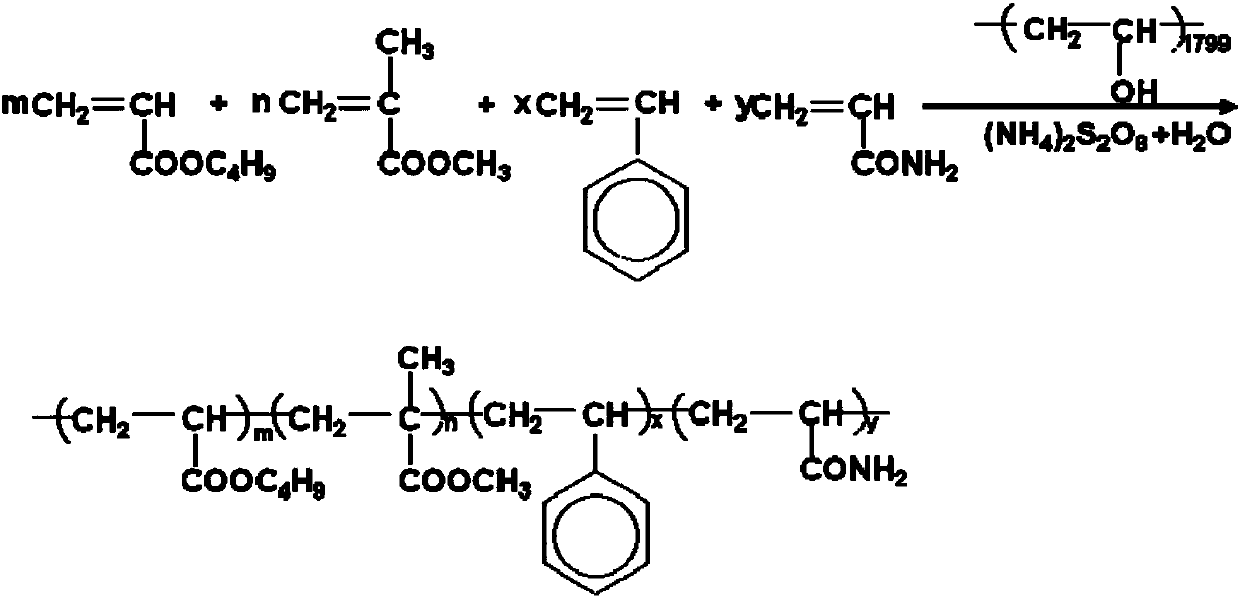

Method used

Image

Examples

Embodiment 1

[0036] Add 100g concentration to be 15% PVA aqueous solution, 50g NaHCO 3 , 10g TX-10, 250g H 2 O, adjust the temperature to 50-90°C, stir well; then add 75g (NH 4 ) 2 S 2 o 8 Aqueous solution; respectively add 50g of BA, MMA, ST, AM in the funnel, 3h dropwise addition; after continuing to keep warm for 1h, cool to room temperature, pour out the liquid material; add 200g of the gained liquid material into the mixing tank, keep The rotation speed is 300 rpm, stirring for 0.5h; then slowly add 200g of water into the mixing tank, and then stir for 0.5h; then add 5g of polydimethylsiloxane into the mixing tank to disperse for 10 minutes, and then put Increase the stirring speed to 600 rpm and add 2.5g of copper 8-hydroxyquinoline into the mixing tank and stir for 50 minutes, then the material can be packaged.

Embodiment 2

[0038] In the four-necked flask that condenser tube thermometer, dropping funnel, stirrer are housed, add 150g concentration be the PVA aqueous solution of 9%, 55g NaHCO 3 , 10g TX-10, 300g H 2 O, adjust the temperature to 50-90°C, stir well; then add 80g (NH 4 ) 2 S 2 o 8 Aqueous solution; respectively add 50g of BA, MMA, ST, AM in the funnel, and dropwise add in 3h; after continuing to keep warm for 1h, cool to room temperature, pour out the liquid material; add 250g of the gained liquid material into the mixing tank, keep The rotation speed is 300 rpm, stirring for 0.5h; then slowly add 250g of water into the mixing tank, and then stir for 0.5h; then add 15g of polydimethylsiloxane into the mixing tank to disperse for 10 minutes, and then put The stirring speed is increased to 600 rpm and 4g of copper 8-hydroxyquinoline is added to the mixing tank and stirred for 50 minutes, and then the material can be packaged.

Embodiment 3

[0040]In the four-necked flask that is equipped with condenser tube thermometer, dropping funnel, stirrer, add 200g concentration and be 5% PVA aqueous solution, 60g NaHCO 3 , 15g TX-10, 350g H 2 O, adjust the temperature to 50-90°C, stir well; then add 90g (NH 4 ) 2 S 2 o 8 Aqueous solution; respectively add 50g of BA, MMA, ST, AM in the funnel, and drop it in 3h; after continuing to keep warm for 1h, cool to room temperature, pour out the liquid material; add 300g of the gained liquid material into the mixing tank, keep The rotation speed is 300 rpm, stirring for 0.5h; then slowly add 300g of water into the mixing tank, and then stir for 0.5h; then add 30g of polydimethylsiloxane into the mixing tank to disperse for 10 minutes, and then put The stirring speed is increased to 600 rpm and 5g of copper 8-hydroxyquinoline is added to the mixing tank and stirred for 50 minutes, and then the material can be packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com