A kind of rigid coupling that can be used for high-speed rotary connection and its preparation method

A rigid coupling, high-speed rotation technology, used in rigid shaft couplings, couplings with safety disconnect joints, couplings, etc., can solve the problem of large installation space, small torque transmission, shaft, bearing, etc. and other problems such as failure of moving parts, to achieve the effect of reducing concentricity requirements, protecting from damage, and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

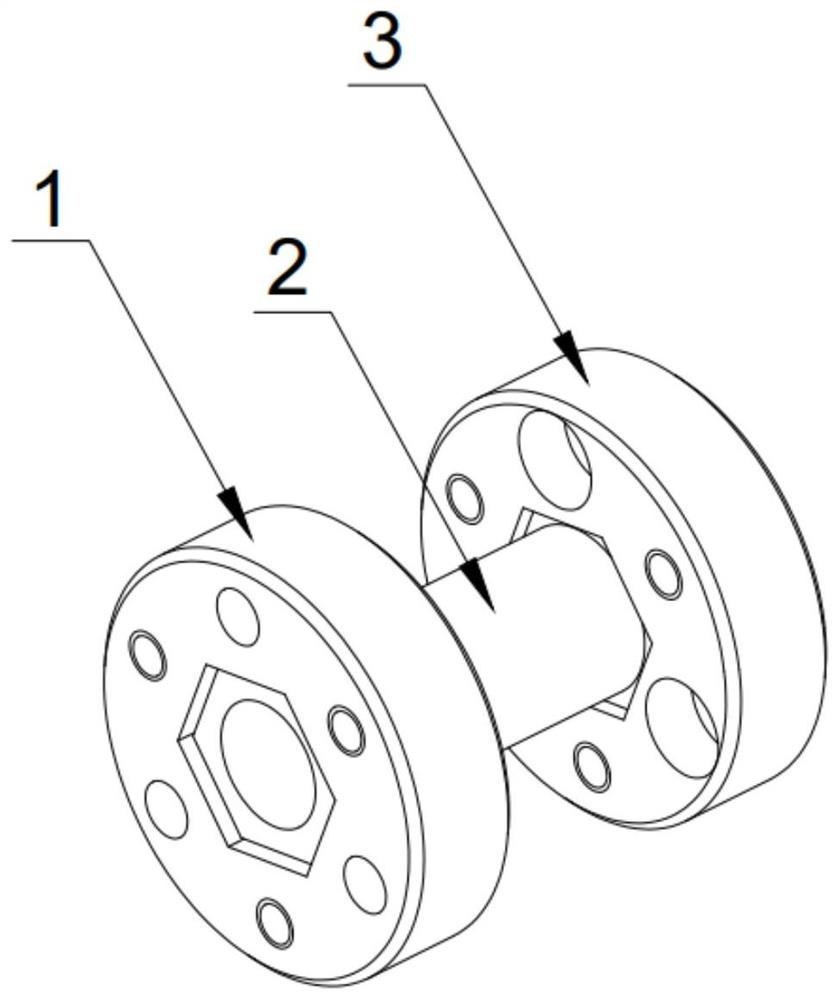

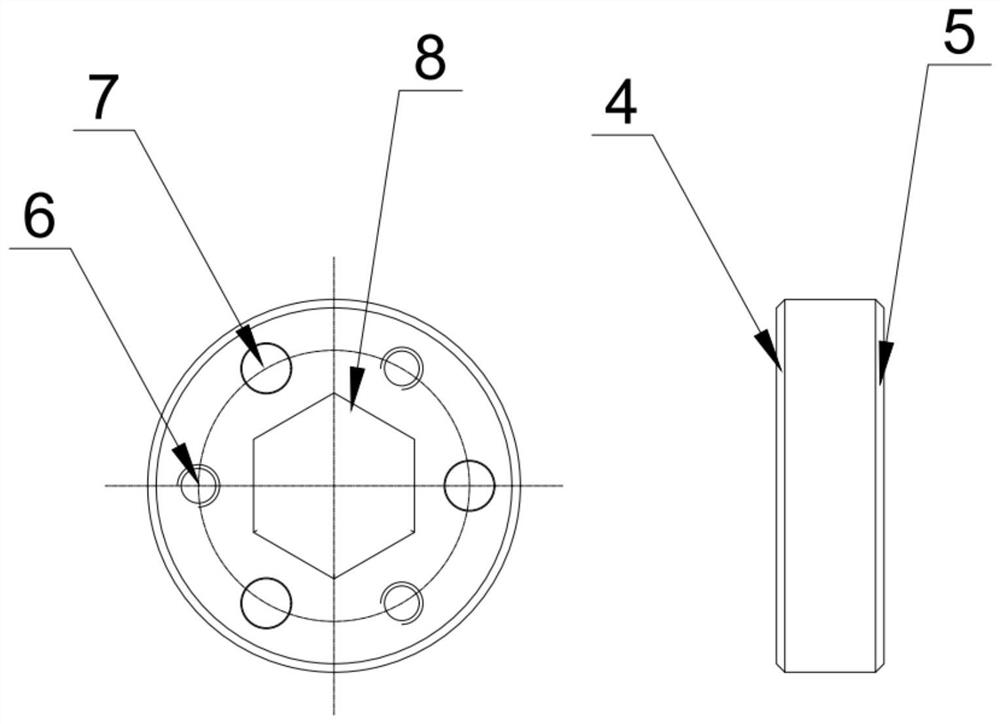

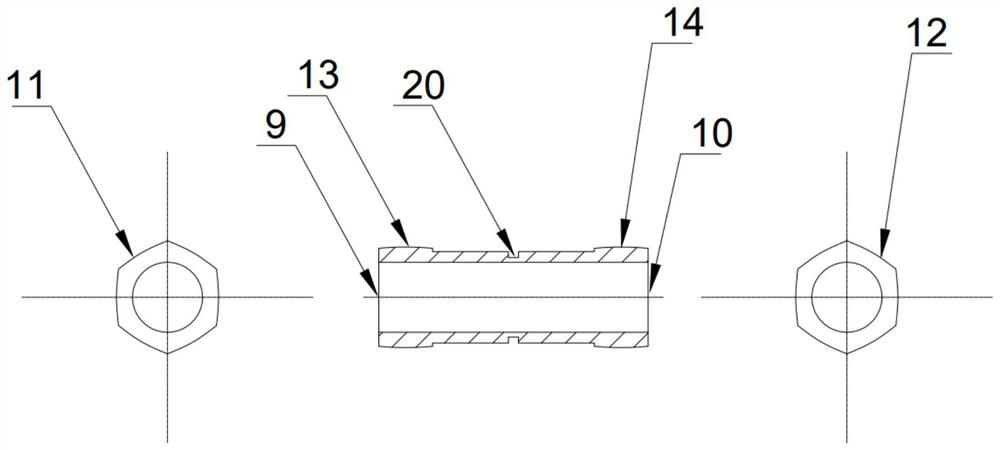

[0025] Example: see attached Figure 1-4 , the present invention provides a technical solution: a rigid coupling that can be used for high-speed rotary connection, which includes a left connecting flange 1, a connecting shaft 2 and a right connecting flange 3, and the center of the end surface of the left connecting flange 1 runs through A regular hexagonal inner hole 8 is provided, and on the end face of the left connecting flange 1, there are a plurality of threaded holes 6 and counterbore 1 7 in a circular array centered on the regular hexagonal inner hole 1 , and the left connecting flange 1 passes through The regular hexagonal inner hole-8 is fitted on the left end b13 of the connecting shaft 2; specifically, the left connecting flange 1 is fixed on the user's driving shaft through the counterbore-7 (or threaded hole-6) thereon .

[0026] The center position of the end face of the right connecting flange 3 is provided with a regular hexagonal inner hole 19, and the end f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com