Device and method for testing interface slippage performance of fiber composite material rod and binder

A fiber composite material and testing device technology, which is applied in the direction of measuring devices, analyzing materials, adopting mechanical devices, etc., can solve problems such as inaccurate measurement results and measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

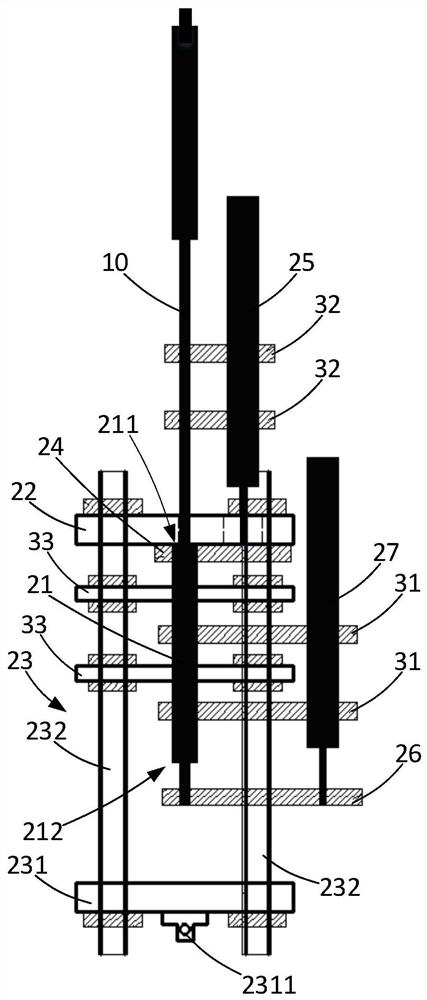

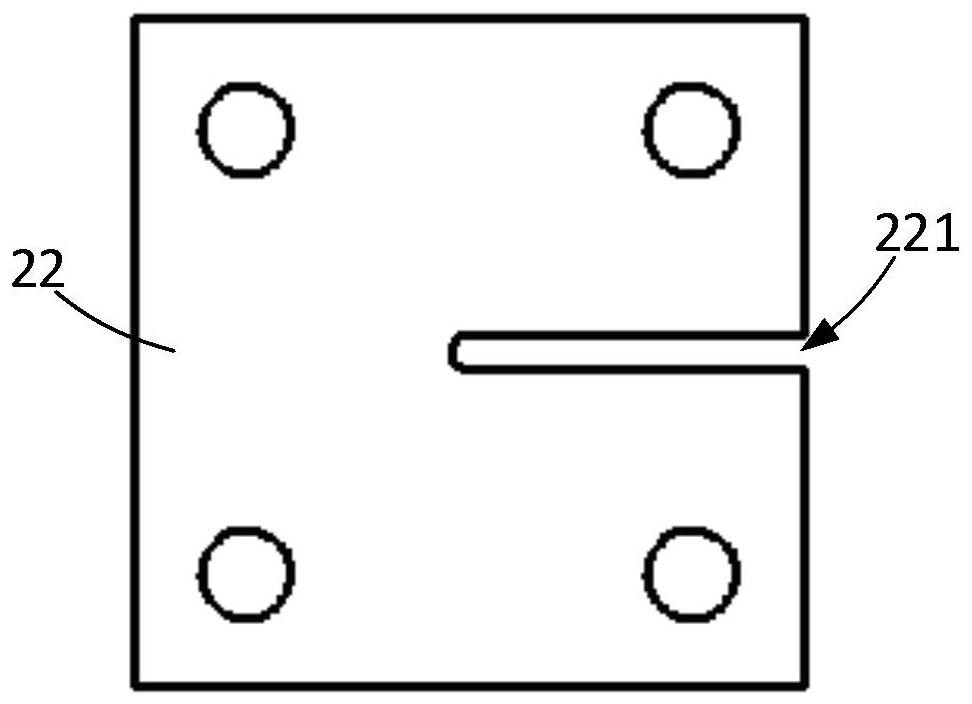

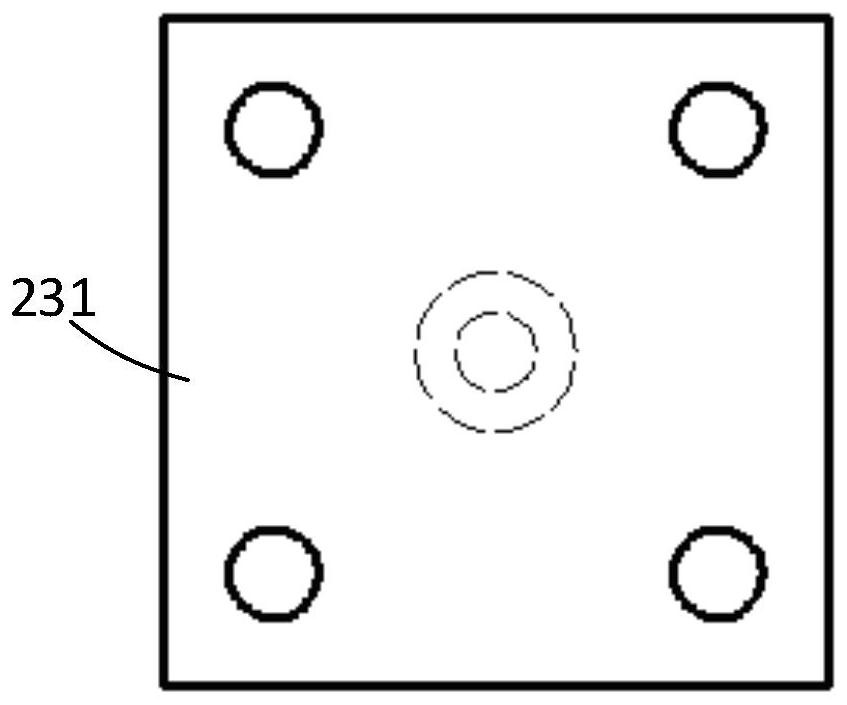

[0044] refer to figure 1 , the present invention provides a device and method for testing the sliding performance of the fiber composite material rod and adhesive interface, which has the characteristics of convenient operation, easy modification and high measurement accuracy, and can realize the measurement limit of fiber reinforced composite material rod and bonding Slip properties at the agent interface. The testing device and method ensure that the displacement of the casing is zero by leaning against the plate to tightly top the casing, reduce the influence of casing sliding on the result, and improve the accuracy of the test result. The device and method for testing the sliding performance of the interface between a fiber composite material rod and an adhesive according to the present invention will be described below with reference to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com