High-precision micro-water sensor zero drift correction method and storage device

A micro-water sensor and zero-point drift technology, which is applied to instruments, scientific instruments, and measuring devices, can solve problems such as unreliable zero-point calibration results, reduce procurement cycles and costs, and avoid unreliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

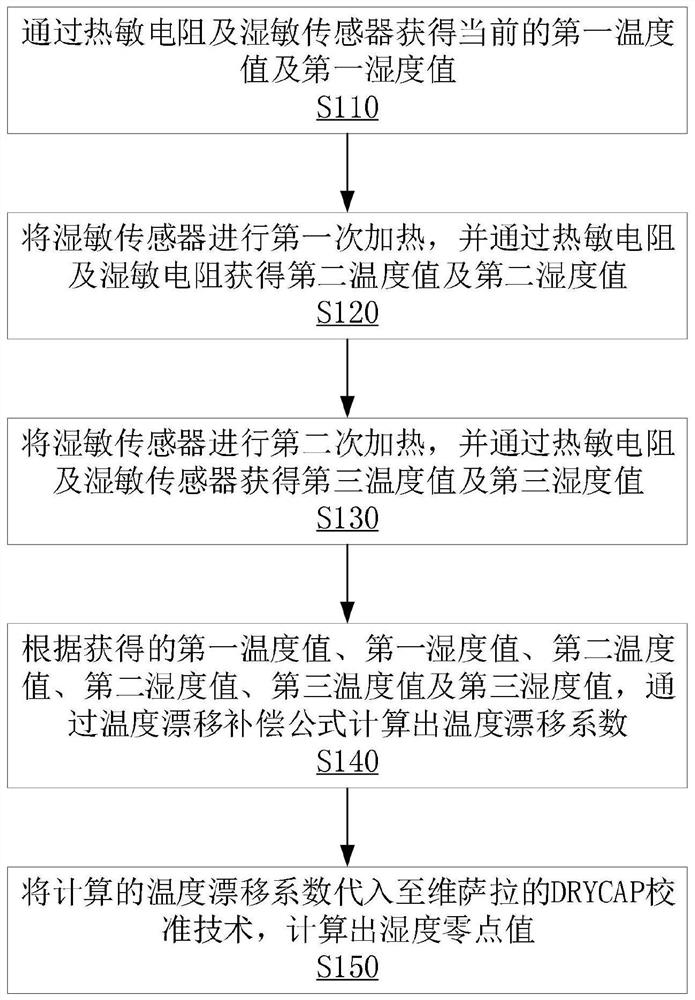

[0032] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

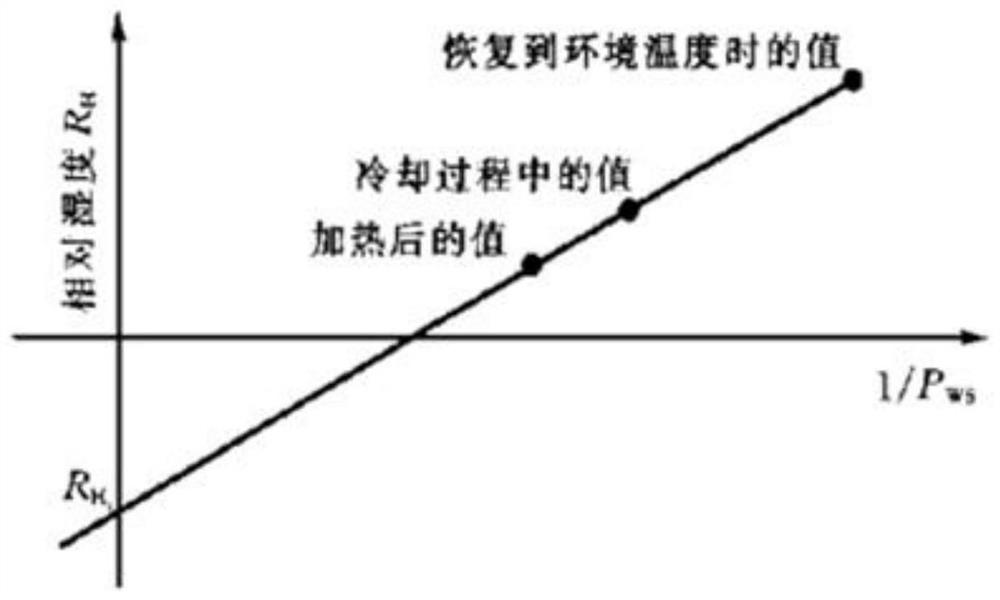

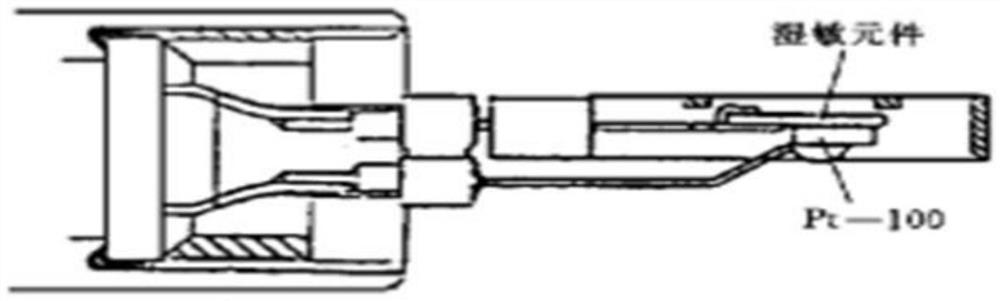

[0033] Such as Figure 1-2 As shown, in the DRYCAP calibration technology of Vaisala, Finland, the DRYCAP probe includes a polymer humidity-sensitive film capacitor and a thermistor. The capacitance value is proportional to the humidity value. The thermistor is used to heat the humidity-sensitive capacitor and record the cooling process. temperature value in . During the heating and cooling process, two sets of temperature values T1 and T2 were recorded, and two sets of humidity values RH1 and RH2 were recorded at the corresponding temperature, and Rh was the zero point drift of humidity.

[0034] According to the GO-ff-Gratch and Wexler correction formula, the saturated water vapor pressure (Pws) at temperature T can be obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com