Unit pole piece preparation method, unit pole piece and lithium battery

A pole piece and foil technology, which is applied in the field of cell preparation, can solve the problems of high production cost and large slurry waste, and achieve the effects of preventing slurry waste, avoiding slurry waste, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

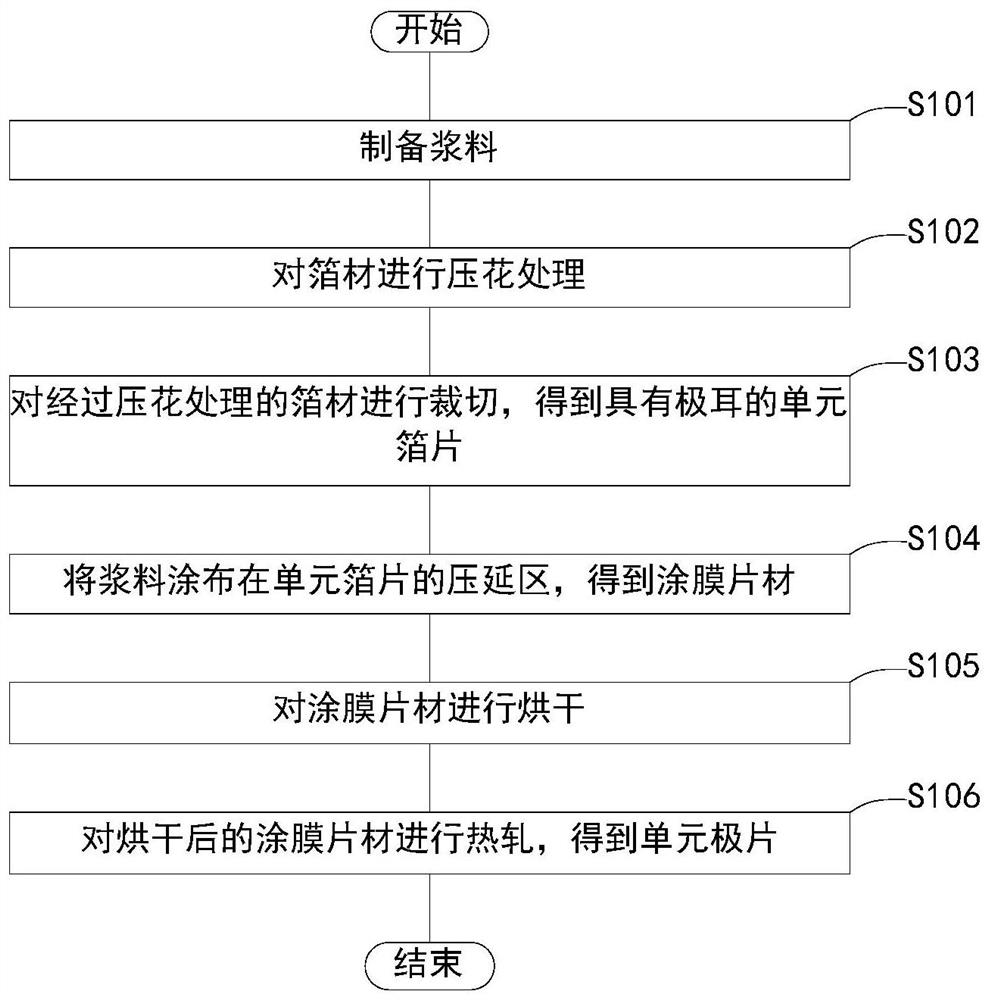

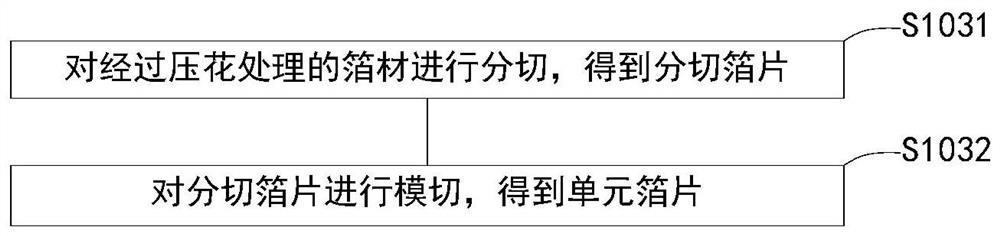

[0053] see figure 1 , figure 1 Shown is a flow chart of the method for preparing a unit pole piece provided in this embodiment. The method for preparing a unit pole piece can avoid waste of slurry and save production costs. The preparation method of the unit pole piece comprises the following steps:

[0054]Step S101, preparing slurry.

[0055] Mix the powder with the solvent to obtain a slurry that meets the process requirements. In order to prevent the slurry from cracking and falling off after coating, in this embodiment, the prepared slurry has a solid content of 75% to 85% and a viscosity of 5000mpas to 100000mpas.

[0056] Moreover, after the preparation of the slurry is completed, the slurry needs to be sealed and stored in an environment with a humidity less than or equal to 20%.

[0057] Step S102, embossing the foil.

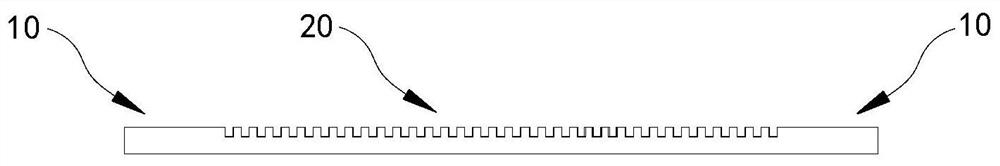

[0058] see figure 2 , figure 2 Shown is a schematic cross-sectional view of the foil after it has been embossed. In this embodiment, an embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap