Liquid level instrument communication module for skid-mounted oil tank and communication method

A technology of communication module and liquid level meter, applied in the field of liquid level meter communication, can solve the problems of disconnection of communication, complex and changeable, inaccurate data transmission, etc., to achieve accurate data transmission, data transmission, and long-term high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

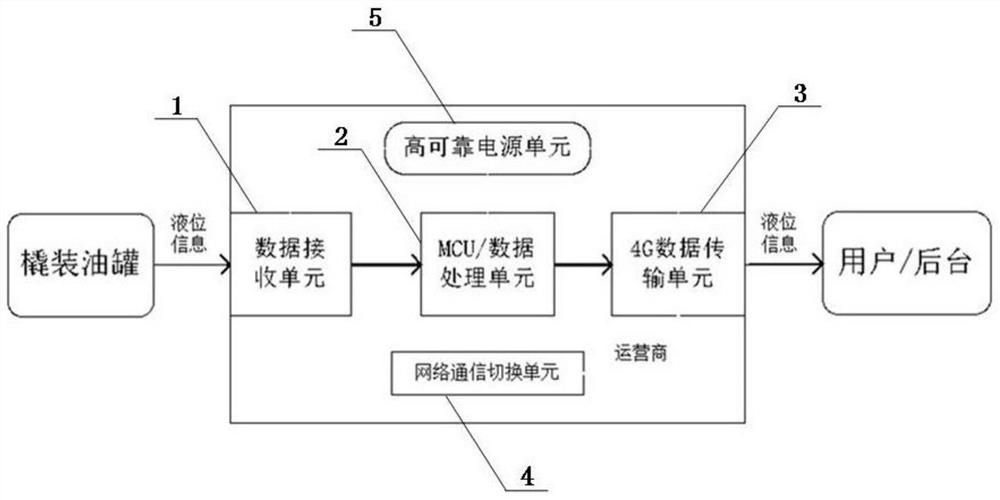

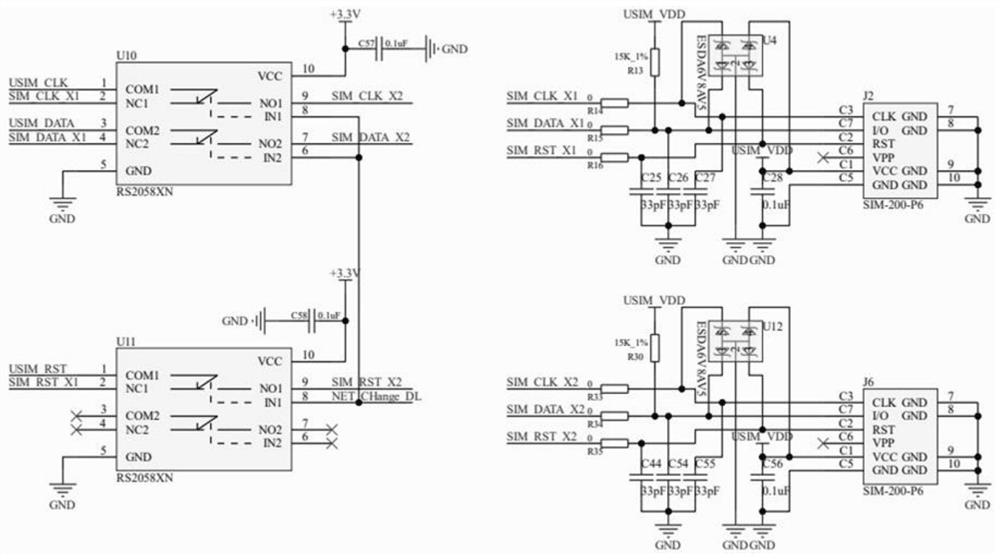

[0038] figure 1 It is a schematic structural diagram of a liquid level instrument communication module provided by Embodiment 1 of the present invention. As shown in the figure, the liquid level instrument communication module includes: a data receiving unit 1 , a data processing unit 2 , a 4G data transmission unit 3 and a network communication switching unit 4 . The network communication switching unit 4 includes an analog electronic switch 41 and a two-way Internet of Things card slot 42; the data receiving unit 1 communicates with the liquid level sensor of the skid-mounted oil tank; the data receiving unit 1, the data The processing unit 2 is sequentially connected to the 4G data transmission unit 3; the 4G data transmission unit 3 is communicatively connected to the background system.

[0039] In the present invention, a network communication switching unit 4 with a dual-card mode is added to the communication module of the liquid level meter, and two Internet of Things...

Embodiment 2

[0051] In order to illustrate the working principle of the communication module of the liquid level instrument, this embodiment provides a communication method for the communication module of the liquid level instrument, which includes the following steps:

[0052] Step 1: using the data receiving unit to obtain liquid level information from the liquid level sensor of the skid-mounted oil tank;

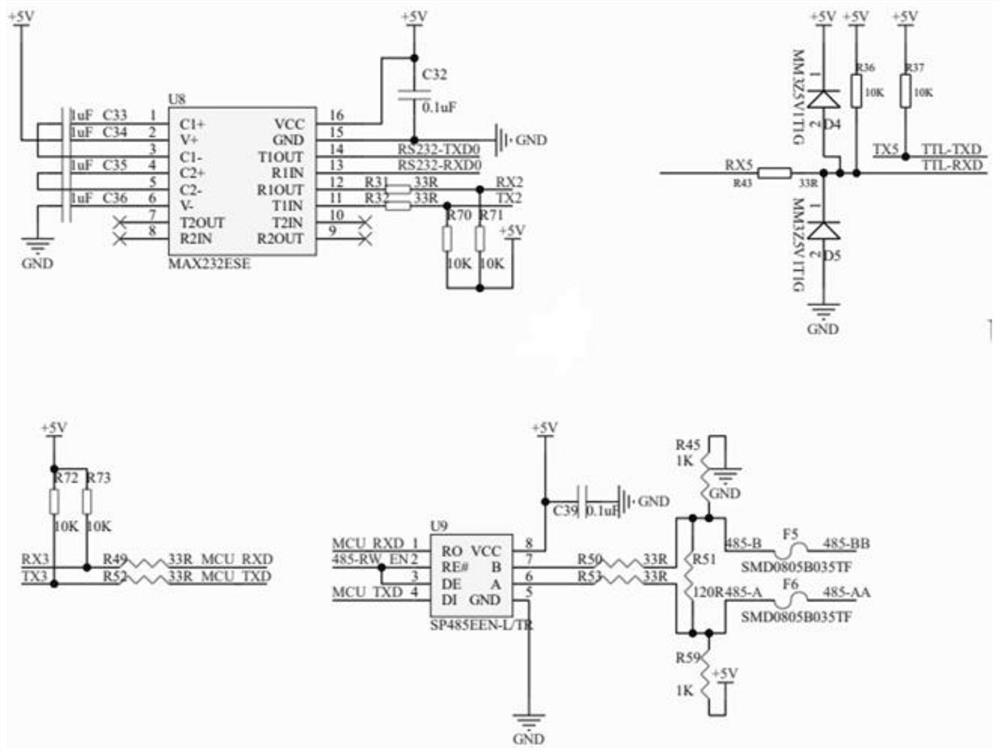

[0053] Step 2: Select one of the RS232 communication mode and the RS485 communication mode, and transmit the liquid level information to the data processing unit;

[0054] Step 3: using the data processing unit to analyze the liquid level information, and sending the analysis result to the 4G data transmission unit;

[0055] Step 4: Using the 4G data transmission unit to send the analysis result to the background system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com