Interference layer system without carrier substrate, method for producing same, and use thereof

A carrier substrate and interference layer technology, applied in the field of interference layer system, can solve the problem of limited spectral characteristics adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0222] example

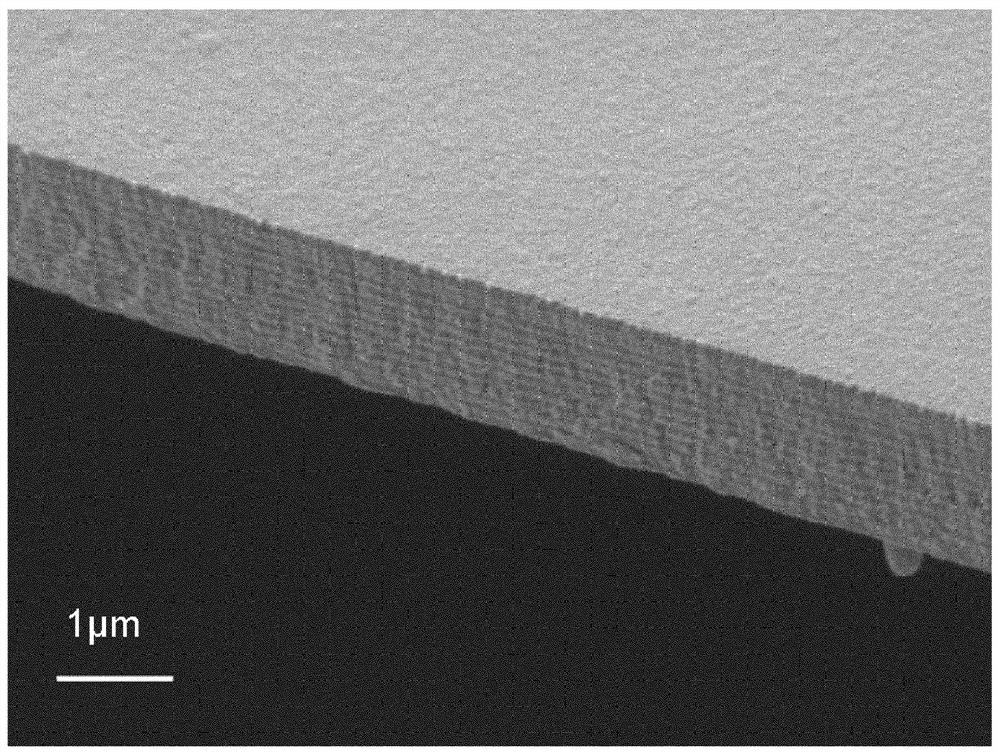

[0223] In the Satisloh 1200-DLF coating unit, an extensive substrate material in the form of a plastic substrate coated with polysiloxane-based hardcoat material MP-1154D (SDC TECHNOLOGIES, INC.) was used as A carrier base material is provided.

[0224] The plastic base material was an uncoated ophthalmic lens made of CR39 polymer and had a circular diameter of 6.5 cm, and a median thickness of 1.5 mm. First, primer PR-1156 (SDC TECHNOLOGIES, INC.) was applied to the plastic base material by dip coating in a layer thickness of 750 nm. Dry in a ULE 600 upright oven at 70 °C for 5 min at D-91126 Memmert GmbH + Co. KG, Schwabach, Germany. The polysiloxane-based hardcoat material MP-1154D was subsequently applied by dip coating with a layer thickness of 2500 nm. It was then dried and cured for 120 minutes at a temperature of 110°C in a ULE 600 upright oven of the company D-91126 Memmert GmbH + Co. KG in Schwabach, Germany.

[0225] Before the actual deposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com